Instruments for Elevator System Debugging and Diagnosis

Feb 1, 2019

An overview of systems used in elevator electricals and useful tools that help troubleshoot them

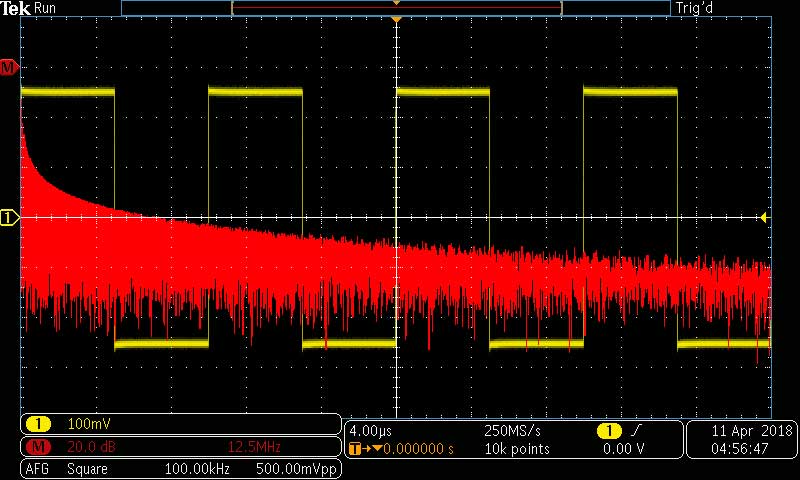

A spectrum analyzer resembles the more-familiar oscilloscope, but there are major differences. Both are very useful in elevator servicing and product development. The defining difference is that the oscilloscope is optimized to display electrical signals that are applied to the input(s) in the time domain, while the spectrum analyzer displays signals exclusively in the frequency domain (Figures 1 and 2).

In the time domain, a waveform is graphed in Cartesian coordinates. The X-axis is defined in units of time (usually seconds or fractions thereof ), while the Y-axis is defined in volts or fractions of a volt. The trace displayed on the oscilloscope screen tells us the instantaneous amplitude of the signal at any point in time.

The frequency domain is also a graph of the signal displayed in Cartesian coordinates. But, this same signal has a strikingly different appearance, which is solely due to the fact that the X-axis is defined in terms of frequency, rather than time. (In mathematics, the word “domain” applies to the independent variable, which, by convention, is plotted against the horizontal X-axis. The word “range” applies to the dependent variable, which, by convention, is plotted against the vertical Y-axis. You input the independent variable into an equation, apply the function, and the dependent variable appears at the output.)

Learning Objectives

After reading this article, you should have learned about:

♦ Test and measurement tools for elevator troubleshooting

♦ Advantages in a PC-based spectrum analyzer.

♦ Differences between time and frequency domains.

♦ Structure of a VFD.

♦ How PWM is used to control speed of an AC induction motor.

In the frequency domain, amplitude is plotted against the Y-axis, as in the time domain. A difference is that, in the frequency domain, amplitude is displayed in units of power (the product of voltage and current), rather than just volts. Also, the default scale is logarithmic, rather than linear, foreshortening the high end of the scale so that tall spikes can be displayed, while greater detail is shown at the low end. The logarithmic units, accordingly, are decibels. Each unit is a tenfold increase in amplitude. This is the way we see light and hear sound.

Most of today’s digital oscilloscopes can display signals in the frequency, as well as the time, domains. They do this by applying the Fast Fourier Transform (FFT) to the time domain signal. This involves a mathematically complex set of algorithms, but the user implements it by simply pressing two buttons in sequence: “Math” and “FFT.”

The frequency domain display shows the spectral distribution of all signal components. A perfect sine wave has no harmonics, so all you see is a single tall spike that represents the fundamental. A signal that is not a sine wave is also composed of a strong fundamental. However, this fundamental is accompanied by a series of harmonics that appear in the frequency domain as additional spikes at amplitudes that diminish as the harmonics are located further in frequency from the fundamental.

The frequency domain, as displayed in the oscilloscope, is sort of a side issue. As stated above, an oscilloscope is optimized to display signals in the time domain. It is useful to see a signal in the frequency domain, but the more-advanced technicians are satisfied with nothing less than the truly amazing spectrum analyzer. That is because it has potentially greater frequency range with greater resolution, faster response and several advanced features that permit the user to extract extensive data not available in the oscilloscope.

The spectrum analyzer is enormously useful in elevator servicing and product development, particularly when it comes to examining digital circuits and transmission lines, notably CAN bus, as used extensively in the motion controller and its interaction with the elevator’s many sensors and readouts, and the pulse- width-modulation (PWM) signal that controls the inverter section of the variable-frequency drive (VFD), which regulates speed and torque of an AC induction motor.

However, two problems arise in deploying a spectrum analyzer. For one, we must recognize the fact that this instrument has a rather steep learning curve. The controls, at first, are not familiar to the user; the readouts have strange names and units; and the menus interact with the display in ways that are perplexing and not, at first, intuitive. Just learning to center the display can be a challenge. But, after a few days of reading the documentation and practicing on various waveforms, it begins to makes sense and, eventually, becomes familiar.

The other spectrum analyzer aspect that may be problematic is the price. The sad reality is that spectrum analyzers are substantially more costly than digital oscilloscopes. A midrange instrument may have a price tag of close to US$50,000, which is OK for the National Aeronautics and Space Administration and European Organization for Nuclear Research, but not doable for technicians outside of an advanced lab or production facility.

Recently, the price gap has closed and, in fact, gone the other way. Tektronix has introduced a PC-based spectrum analyzer that connects via USB to a user-supplied PC. Since nearly everyone on the planet owns or has access to a PC, the cost of the computer does not have to be a factor. The Tektronix RSA306B PC-Based Spectrum Analyzer can be obtained for under US$4,000.

The manufacturer also furnishes in a flash drive (or as a download from the website) SignalVu-PC, which is the software that, once installed on the user’s computer, enables it to display signals from the module in the frequency domain in an elaborate onscreen interface that is fully interactive. There is also a high- functioning Demo Three board that provides an array of signals designed to bring the user up to speed and ready to engage in big troubleshooting and debugging projects.

Elevator troubleshooting is primarily an electrical/electronic undertaking. While it is true that equipment malfunction can be purely mechanical, as in a door binding and failing to close properly, most faults are either purely electrical or have a strong electrical component. These may be divided into two categories, having to do with the voltage level. The elevator motor requires a relatively high operating current, which is delivered most efficiently by a three-phase, high-voltage supply. There are still lots of legacy DC motors in service, and in an elevator overhaul, it often makes sense to retain the DC system, which requires only a simple rectifier to operate smoothly and efficiently, the principle maintenance consisting of periodic brush replacement. New installations and most renovations, however, choose the lower-cost three-phase induction motor powered by a VFD (Figure 3), which is often located, along with the motion controller, in a floor-to- ceiling steel enclosure in the machine room.

The VFD consists of two sections connected by what is known as the DC bus. At its input is the rectifier section, made up of six diodes that comprise a full-wave rectifier. Each of the three legs (L1, L2 and L3) is connected to the midpoint of a pair of diodes. The outputs of these three pairs of electrolytic capacitors are connected to the positive (+Vdc) and negative (-Vdc) sides of the DC bus after the DC filter and buffer, which remove AC ripple to create a pure DC.

A safe way to measure voltages that float above but are referenced to ground is by means of a differential probe. Notice that the center point, defined by the two capacitors, which form a voltage divider, is grounded. This is very important, because it means the positive and negative DC lines that are the DC bus are both referenced to but float above ground potential. Neither is grounded. Consequently, if a conventional bench-type oscilloscope with a ground(ed) reference lead as part of the probe is connected to the DC bus, there will be a severe ground fault, sparks will fly, and oscilloscope and VFD may be damaged.

Safe ways to measure this voltage will follow. First, continuing along the current path to the motor, it must be said the voltage on the DC bus is higher than the AC voltage fed to the rectifier at the VFD input. The reason for this puzzling phenomenon is that the DC output of a full-wave rectifier relates not to the AC RMS input, but rather to the peak-to-peak voltage of that waveform. Accordingly, for the three-phase, 480-V VFD typical in elevator installations, the voltage at both ends of the DC bus is 1.414 times the line voltage, so it measures very close to 678 VDC.

The final, inverter section of the VFD is a mirror image of the front-end rectifier section regarding component layout, but the components are different. Rather than six diodes that compose the full-wave rectifier, the essential components in the inverter section are insulated-gate bipolar transistors.

In the rectifier section, the three-phase sinusoidal utility power is combined, rectified and filtered to make bipolar DC, as required at the six semiconductor power inputs. There are also, as in typical transistors, six signal inputs (not shown for clarity in the schematic) at these switching semiconductors. These devices can power 500-hp loads. The PWM low-voltage signal from the remote user interface and/or automatic controller causes the semiconductors to switch on and off in phase sequence to create a three-phase pulse, the width of which is modulated to control the motor speed. This high-voltage, high-current energy is conveyed through appropriate cabling to the motor.

To power an elevator, an AC motor must be capable of reversing direction, and, for a three-phase motor, this is simple enough. By means of appropriate switching, manual or automatic, any two of the three legs are reversed. However, a good elevator installation also requires smooth and reliable speed control. For example, as the elevator car approaches a landing, motor RPM is reduced so that the passengers are not jolted by an abrupt stop. Also, the car is required to move slowly in inspection mode.

In the popular imagination, a large rheostat is turned to reduce voltage to slow the motor. This expedient is not satisfactory for an AC induction motor. At below-rated voltage, AC motor windings become heater elements. The motor is slowed, but this crude method greatly stresses motor windings and insulation, making for a very short service life.

For decades after Nikola Tesla and George Westinghouse in the late 19th century introduced the highly efficient induction motor, the DC motor, with its required rectifier and brush-commutator maintenance, was retained in elevator and similar sensitive applications. This worked, but the far-less-expensive VFD/induction-motor combination, as described above, was introduced in the early 1960s and has since dominated the worldwide market wherever speed control is a factor.

The VFD can vary the speed of an AC induction motor by synthesizing a square wave that has a varying duty cycle. Rather than adjusting the applied voltage, the duty cycle, which is the percentage of time the pulse is high, is adjusted. In this way, the power to the motor can be varied to control its speed without generating excessive heat. The motor can cruise along below or above rated speed with no problem, as long as cooling and bearing constraints are observed. (If it turns slower, a bigger fan might be needed.)

Variation of the duty cycle is known as PWM. A low-voltage PWM signal is generated at a remote human operator interface, which, in an elevator installation, may be decentralized and consists of call buttons, sensors and the like integrated with a motion controller. By means of digital circuitry, the PWM control signal can be synthesized by one of several methods:

- The intersective method makes use of a triangle waveform, easily synthesized by an oscillator, in conjunction with a comparator. The desired signal is compared to the triangle waveform. When it exceeds the triangle waveform, a logic high state is created. When it is less, the result is logic low. This is the digital PWM signal.

- In the delta modulation method, the desired signal is integrated and compared to reference signal limits. The PWM changes state at these reference levels.

- In the delta-sigma method, a reference signal is established, then the output signal is subtracted from it. The error signal so formed is integrated, and, when this signal exceeds limits, the PWM signal changes from logic high to logic low or from logic low to logic high.

- Space-vector modulation is used in three-phase VFDs. A reference signal is sampled at uniform intervals. Then, the reference signal is synthesized as the average of vectors that have been selected as fractions of the sampling period.

- Direct torque control is another method to regulate AC motors. Motor torque and magnetic flux stay within hysteresis limits, because the device semiconductors are switched on as required.

- In the time-proportioning method, a counter fires and is reset at the conclusion of each PWM cycle. The output changes state.

Good resolution is obtained by employing a high-speed counter.

The signal that modulates is nonlinear, and this gives rise to infinite bandwidth in the PWM signal, which is conveyed to the VFD. If motor behavior is erratic, the control signal needs to be verified. An induction motor’s RPM depends on two parameters (the number of poles and the frequency of AC power applied at the input), aside from loading.

As in any AC motor, in an induction motor controlled by a VFD, temperature rise is determined by the current through the windings. When the frequency is reduced, the voltage at its input must also be reduced to limit the current.

A VFD will maintain a uniform volts-to-Hertz ratio at any frequency. Accordingly, PWM characteristics include lower voltage created by narrower pulses that are more numerous during a given time interval. Conversely, higher voltage is created by fewer pulses that are more widely separated. Critically, as mentioned above, the applied voltage is close to a square wave, but the current through the motor more closely resembles a sine wave. This necessary condition is due to the inductive nature of the load.

Elevator troubleshooting is primarily an electrical/ electronic undertaking.

A relatively new development in the ongoing progression of elevator technological innovation has been the introduction of CAN bus as a means for subsystem communication. As in all digital interactivity, the winning strategy in debugging new equipment and diagnosing existing equipment involves understanding how these communication buses work so they can be evaluated.

First, we need to consider precisely what, in data processing, constitutes a bus. In the traditional electrician’s workplace, a bus is a heavy conductor capable of carrying lots of current, frequently at elevated voltage. The bus is typically located inside a service enclosure, rigidly fastened in place on insulating mounting hardware. Since it is not insulated (or, more properly, is insulated by the air that surrounds it), a bus can be more compact than a wire of the same ampacity, so expense and valuable space inside the enclosure are conserved. In digital communication, which is essential in all but the smallest elevator installations, “bus” has a somewhat broader meaning, describing the complete media, including cabling, devices and software.

Buses can be parallel or serial, with fewer conductors. Serial bus systems are less expensive to implement but require greater knowledge and expertise to debug and diagnose. CAN bus is a serial bus introduced by Bosch in 1983. It was intended to replace the automotive wiring harness with an onboard digital system that would link automotive components and systems for motor vehicles in ways that would promote efficiency, economy and safety. It was enormously successful, and is used today worldwide in cars, trucks and tractors.

CAN bus soon spread to many mechanical and industrial applications, including elevator technology, where it was quickly found to be suitable due to economy, noise immunity and reliability in compromising environments. It works well in elevator technology, especially in group installations. Traveling cables are required to carry a modest amount of power for operating doors, lights inside the car, etc. Additionally, serial CAN bus cables are carried to the moving car, and at times, this media, including terminations, must be checked in the course of debugging and diagnosis.

When you consider the high-power conductors and control devices for the elevator motor(s), plus the large quantity of serial CAN bus control wiring, there is a large amount of test and measurement that technicians and engineers are required to do. When it comes to elevator diagnosis and repair, of course, time is of the essence.

In elevator maintenance and fault mitigation, two areas are critical. The first is documentation. In a complex system, maintenance manuals with complete block diagrams and schematics are needed to make sense of the large amount of cabling and printed circuit boards that make it all work. Secondly, technicians need a complete range of test and measurement equipment to check power quality and digital signaling integrity throughout today’s complex electrical systems.

It is important to realize that an array of instrumentation is needed. Regarding power flow to the motor(s), we must realize that a single instrument, such as an oscilloscope or a multimeter, will not suffice to measure voltages and current. A multimeter, spectrum analyzer, clamp-on ammeter and handheld oscilloscope with isolated inputs (from ground and from each other) are needed just to get started. Similarly, in the digital domain, protocol and bus analyzers are valuable, but before beginning digital signal tracing, it is best to take conventional analog measurements of digital pulses to determine if there is excessive noise on the logic high pulses, which would prevent proper rendition at the receiving end.

In digital troubleshooting, simple measurement tools such as the logic probe and multimeter may reveal information that would be missed in a full-scale protocol analysis, which should be undertaken after the preliminary, simpler measurements are completed.

Learning-Reinforcement Questions

Use the below learning-reinforcement questions to study for the Continuing Education Assessment Exam available online at www.elevatorbooks.com or on p. 117 of this issue.

♦ What is the difference between a serial and parallel bus?

♦ Why is CAN bus superior to traditional wiring in sensitive locations?

♦ What is the role of analog instrumentation in digital measurements?

♦ What are the similarities in rectifier and inverter sections in a VFD?

♦ Why is a full-wave rectifier output greater than the AC input?

- Figure 1: Square wave displayed in the time domain

- Figure 2: The same square wave displayed in the frequency domain

- Figure 3: Schematic diagram of a three-phase VFD

Get more of Elevator World. Sign up for our free e-newsletter.