Integrated Safety Valves for Unintended Car Movement

Jan 1, 2018

Integrated Safety Valves for Unintended Car Movement

An additional unintended-car-movement (UCM) safety requirement has been mandatory for new elevators and major modernizations since January 1, 2012, per EN 81-1/2+A3. Later, the requirement was also in the present standard, EN 81-20/-50. The requirement is to prevent UCM while the doors are open. There have been various solutions for traction and hydraulic elevators to satisfy the condition. All introduce additional mechanical, electrical and electronic parts that complicate installations, increase the cost and decline energy efficiency to a certain extent. Blain Hydraulics introduced two new UCM solutions to the hydraulic elevator sector during Interlift (p. 88). This article explains their concepts and discusses their advantages.

The Most-Applied UCM Solution

UCM had already been a necessity for traction elevators because of the counterweight. Though risk analyses of a properly designed hydraulic elevator do not dictate an additional UCM safety, since EN 81-20/-50 imposes it for all elevators, hydraulic elevators also require the UCM safety.

The UCM amendment requires detecting UCM, operating the actuator, stopping the movement within a certain distance and keeping the car stopped. This is managed by adding a redundant safety device to control both up and down movements. Considering all existing UCM solutions, achieving the UCM safety is much simpler for hydraulic elevators than traction elevators. The most-used and simplest solution is to add a second check valve in the cylinder line for down movement and include additional motor contactors in series for upward movement.

The solution for the up direction was solved immediately, but introducing the second check valve could have been an issue. Fortunately, Blain had already possessed an existing solution, the L10 pressure lock valve as the downward solution. L10, a solenoid-operated check valve, is connected between the elevator control valve and the cylinder. In the up direction, the check valve opens with the flow of oil and allows oil to pass through to the cylinder. In the down direction oil cannot pass through the L10 unless the solenoid coil is energized. To initiate downward travel, both solenoid coils on the L10 and on the control valve have to be energized. In this way, redundant safety is provided in the down direction. The coil on the L10 valve is deenergized to stop the car in the case of UCM. UCM detection can be sensed by, for example, a magnetic switch placed not more than 150 mm below the floor level. The L10 valve and its way of connection to the control valve is shown in Figure 1.

New Solutions

L10 is a simple solution by Blain Hydraulics that has been duplicated by many other hydraulic-elevator manufacturers. On the other hand, it has some drawbacks, such as being bulky, overheating the oil, and having low energy efficiency, difficulties in assembling and risk of external leakage. These drawbacks are fully eliminated with the introduction of the integrated L10: iL10 and L20.

iL10 is a solenoid-operated lock valve designed as a safety device against downward UCM for hydraulic elevators. It is a compact solution that has been designed within the down flange of EV-type valves. Basically, the iL10 flange replaces the existing down flange on EV-type control valves to make it UCM compatible. It can be easily applied to 1-2-in. EV- and SEV-type valves. All standard downward adjustments, as well as the self-

closing emergency lowering valve, are the same for the iL10. Therefore, there will be no difficulty in performing valve adjustments. Figure 2 shows the connection of iL10 with an EV100 control valve.

It was not possible to duplicate a similar iL10 solution because of the size of the 3/4-in. EV-series control valves’ down flanges. Instead, existing 3/4-in. L10 valves have been redeveloped and integrated with the 3/4-in. EV-series valves, eliminating the need for fittings and adapters. This new development, L20, has the same working principle as L10 but generates negligible pressure drop, and offers a compact design, ease of assembly, no risk of external leakage and higher energy efficiency. It is shown in Figure 3.

How iL10 Works

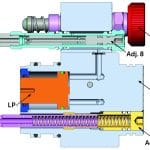

The iL10 flange has an internal lock piston (LP) and a solenoid (A3) as seen in Figure 4. The lock piston is used for locking the main down piston of the EV control valve to its closed position when the elevator is traveling up or stationary. For downward travel, the A3 solenoid coil on the iL10 and the down coils on the control valve should be energized. Energizing only the down coils on the EV control valve does not allow downward travel. When the elevator moves downward more than 150 mm while the doors are open, the lift controller detects a UCM situation and deenergizes the solenoid coil (A3) on the iL10 valve. The elevator decelerates and stops within 800 mm of downward movement with less than 1 g of retardation.

Advantages of iL10 and L20

Compact Design

iL10 is fully integrated with the SEV and EV 1-1/2- and 2-in . valves. It is basically a modified down flange that replaces the existing flange on the control valve. The L20 is fully integrated with EV 3/4-in. valves. As no extra fittings or adapters are required, the size of the complete unit remains compact or even unchanged (as in the case of iL10).

Compatibility

The iL10 and L20 can be integrated into existing Blain control valves without the need to change any existing piping or connectors, and, thus, are also ideal for renovation projects.

Installation

The iL10 and L20 can be either ordered preassembled with a new Blain control valve or as an upgrade to make an existing Blain valve UCM compatible. The iL10 replaces the Blain down flange and requires no separate tank connection. A separate tank connection from the L20 is required for the upgrade. However, for new, factory-assembled valves, no separate tank connection is needed.

Savings

Any device connected in the flow line increases pressure loss and, accordingly, motor size, energy consumption and oil temperature. The integrated iL10 and L20 are energy-efficient solutions by virtue of no or negligible pressure losses. The flange of the iL10 is placed on the control valve; therefore, it does not cause extra pressure loss to the hydraulic system. On the other hand, since the L20 is integrated and has been intelligently designed to reduce pressure losses (by 80%), it generates a negligible amount of pressure loss.

In hydraulic systems, pressure loss is converted into heat and quickly influences oil temperature. Extra pressure losses for frequently used elevators can increase oil temperature to a critical value, so an oil cooler might be necessary. Unlike other solutions, the iL10-flange and L20 are safe for frequent usage without generating excessive heat.

Since the iL10 and L20 are integrated, the risk of external leakage is reduced, and no extra fittings are needed. Thus, the solutions offer considerable savings in fittings and installation time.

Travel Quality

Elevator control valves have a minimum working pressure below which control of oil flow becomes problematic. Any additional pressure drop reduces the minimum control pressure further and deteriorates downward travel quality. Since the iL10 and L20 do not cause extra pressure loss (or only cause a negligible amount of it), they can be safely used in low-pressure applications without disturbing travel quality.

Conclusions

The two new products complement the existing Blain control valves by being integrated inside. They meet the requirements to prevent UCM, compliant with EN 81-20/-50. iL10 and L20 not only simplify the overall assembly, but also overcome the need to use extra adapters and fittings, thereby introducing a compact solution, reducing installation cost and offering greater energy efficiency.

- Figure 1a L10 safety valve and its connection to a control valve

- Figure 1b L10 safety valve and its connection to a control valve

- Figure 2 iL10 flange connected with EV type control valve

- Figure 3a (a) L10 safety valve connected to ¾” EV100 valve, (b) L20 safety valve connected with ¾” EV100 valve.

- Figure 3b (a) L10 safety valve connected to ¾” EV100 valve, (b) L20 safety valve connected with ¾” EV100 valve.

- Figure 4: Components of an iL10 flange

Get more of Elevator World. Sign up for our free e-newsletter.