It’s In The Groove

Sep 1, 2021

In this Readers’ Platform, your author emphasizes that the rope prefers a U-groove.

Whether it’s in baseball when a hitter is “in the groove” and seems to be crushing the ball, or a golfer who has his “putting groove on” and drains every putt, being in the groove is where one loves to be. When it comes to ropes, this statement has a few qualifiers with it. Not only does a rope prefer a U-groove, but it prefers a full-round U-groove, with a 6% larger radius than that of the nominal diameter of the rope. If that is not the case, we can start calculating the crushing of the rope, instead of the ball, and the draining of the lifetime of the rope instead of the putts. The effects of more-aggressive grooves, such as V-grooves and undercut U-grooves, are not unknown, and one should understand the effects — both the benefits as well as the cost — of using these aggressive groove types. Before we can discuss any calculations, let’s first look at some of the different groove types that are used today, and the reasons behind using them.

First of all, with space becoming more and more expensive, efforts have been made to consume less of it with elevator machine rooms, which is evidenced by the number of machine-room-less (MRL) elevators in use today. This desire to occupy less space has led to smaller machines, which free up space but not without a cost. When one examines the torque requirements of a large machine (which can be directly correlated to energy consumption) versus that of a smaller machine, it’s easy to see the smaller machine requires less torque and, therefore, less energy consumption, which is a positive but, again, not without a cost.

For the purpose of examining torque, consider “machine size” to be the same as “traction sheave size.” The basic definition of torque is “![]() ,” in which

,” in which ![]() = torque, r = radius, F = force and

= torque, r = radius, F = force and ![]() = the angle between F and what is known as the “moment arm.” In a traction elevator, one can consider

= the angle between F and what is known as the “moment arm.” In a traction elevator, one can consider ![]() to be equal to 90° and, since the

to be equal to 90° and, since the ![]() , we can say

, we can say ![]() , or torque needed, is equal to the radius of the traction sheave times the force required. From there, one can see that as the radius gets smaller, the torque requirement is reduced. This is a positive as it relates to the size of the motor, but what has this done to the traction of the system? With a smaller sheave, and thus reduced arc of contact between the rope and the sheave and the need to achieve the same available traction, one has to increase the pressure between the rope and the sheave, i.e. the groove pressure. This can be done by undercutting the U-groove or utilizing a V-groove. The practical effect of undercutting the U-groove or using a V-groove is the rope is no longer fully supported in the U-groove, and there is less area of the rope in contact with the sheave. If we have the same loads distributed over a smaller area, it’s easy to see how the “groove pressure” itself would be increased.

, or torque needed, is equal to the radius of the traction sheave times the force required. From there, one can see that as the radius gets smaller, the torque requirement is reduced. This is a positive as it relates to the size of the motor, but what has this done to the traction of the system? With a smaller sheave, and thus reduced arc of contact between the rope and the sheave and the need to achieve the same available traction, one has to increase the pressure between the rope and the sheave, i.e. the groove pressure. This can be done by undercutting the U-groove or utilizing a V-groove. The practical effect of undercutting the U-groove or using a V-groove is the rope is no longer fully supported in the U-groove, and there is less area of the rope in contact with the sheave. If we have the same loads distributed over a smaller area, it’s easy to see how the “groove pressure” itself would be increased.

Understanding a few reasons behind the desire or need to have these more-aggressive grooves, we can now look at a few methods of calculating the number of bends that can be expected with the different types of grooves, as well as a method of equating one bend of an “aggressive” groove to that of a full-round U-groove. Once this is done, we can evaluate the cost side of the equation to see if the benefit is worth the cost, or at least understand what our expectations should be.

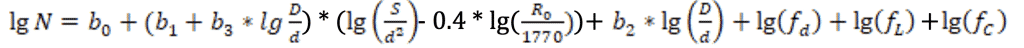

First, let’s look at the standard equation that is used by many in the industry. It’s commonly referred to as “Feyrer’s Lifetime Equation,” which was developed by Professor Klaus Feyrer of the University of Stuttgart in Stuttgart, Germany. Below is the basic equation to determine the number of simple bends one could expect:

There are various factors that must be taken into account when utilizing the Feyrer equations, but they will not be discussed in depth here. Instead, we will focus on one factor referred to by Feyrer as the “endurance factor,” known as ![]() and pertinent to the sheave groove. These endurance factors are factors that, when multiplied with the calculated number of bends obtained from Feyrer’s lifetime equation, produce a corrected number of expected bends.

and pertinent to the sheave groove. These endurance factors are factors that, when multiplied with the calculated number of bends obtained from Feyrer’s lifetime equation, produce a corrected number of expected bends.

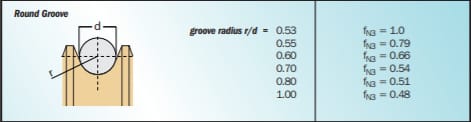

![]() is the factor describing the effect the groove design has on the lifetime of the rope. As mentioned above, a rope prefers to operate in a groove that has a radius 6% larger than the nominal diameter of the hoist rope. This is seen when one looks at the factors for the various sizes of standard U-grooves.

is the factor describing the effect the groove design has on the lifetime of the rope. As mentioned above, a rope prefers to operate in a groove that has a radius 6% larger than the nominal diameter of the hoist rope. This is seen when one looks at the factors for the various sizes of standard U-grooves.

The table below shows the factors for such grooves.

If we examine the ![]() factor for a groove that is 6% larger than nominal rope,

factor for a groove that is 6% larger than nominal rope, ![]() , we will see that the value for

, we will see that the value for ![]() is 1.0. To look at it another way, if one has calculated the expected life in a given installation to be 1,000,000 (1 million) bends, to apply the

is 1.0. To look at it another way, if one has calculated the expected life in a given installation to be 1,000,000 (1 million) bends, to apply the ![]() factor, one would simply multiply the calculated number of bends times the factor to obtain the “corrected number of bends,” i.e., 1,000,000 x 1.0 = 1,000,000. We can see that the basis for the groove factor is the 6% larger, full-round U-groove. If this same given installation were to have a groove that was, for example, 10% larger, the lifetime would be diminished. Although still a full round U-groove, the rope is not supported as it should be and the corrected number of bends would be 1,000,000 x 0.79 = 790,000 bends. Although not part of the round groove factors provided as part of Feyrer’s research, and the fact that most ropes are produced slightly larger than their nominal value, it is thought than any round U-groove that is less than 6% over the nominal rope diameter will also have a negative effect on rope life.

factor, one would simply multiply the calculated number of bends times the factor to obtain the “corrected number of bends,” i.e., 1,000,000 x 1.0 = 1,000,000. We can see that the basis for the groove factor is the 6% larger, full-round U-groove. If this same given installation were to have a groove that was, for example, 10% larger, the lifetime would be diminished. Although still a full round U-groove, the rope is not supported as it should be and the corrected number of bends would be 1,000,000 x 0.79 = 790,000 bends. Although not part of the round groove factors provided as part of Feyrer’s research, and the fact that most ropes are produced slightly larger than their nominal value, it is thought than any round U-groove that is less than 6% over the nominal rope diameter will also have a negative effect on rope life.

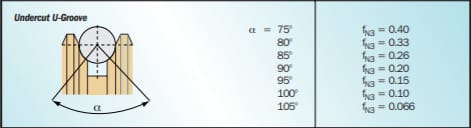

Staying with the same given installation with 1,000,000 calculated bends, let us look at changing the groove type to an undercut. This can be necessary, as previously stated, due to the traction requirement. The factors for this groove geometry were developed from 75° up to 105° in increments of 5°, as shown below.

Performing the same calculation as before, but with a 90° undercut U-groove, one will obtain the following results: 1,000,000 x 0.20 = 200,000, or an 80% reduction in the life of the rope verses a round U-groove. In some cases, it is necessary due to the traction requirements to go all the way to a 105° undercut. In these cases, one would calculate 1,000,000 x 0.066 = 66,000 trips, or over a 93% reduction in rope life.

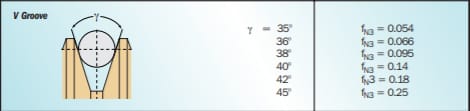

The final groove that we will look at is the V-groove. This groove type does have the benefit of generating the maximum traction when new or if sufficiently hardened as to prevent loss of its shape, but also has the largest cost associated with it. If the traction can be achieved with a 45° opening, then the cost is “only” 75% of the rope life, but if we were to go to the extreme of a 35° V, we would calculate (again with the same given install) 1,000,000 x 0.054 = 54,000 bends, or a 94.6% reduction in lifetime.

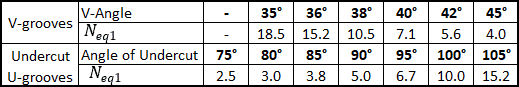

Another method of looking at the effect that groove profiles or shapes have on the lifetime of the rope is to equate the number of bends on an aggressive groove, undercut or V, to the number of bends it would take to cause the same “damage” if the bending were taking place on a full-round U-groove, or “equivalent sheaves.” According to Lubomir Janovsky, one can evaluate a system by calculating the amount of equivalent bends if the profile were again 6% larger than a nominal full-round U-groove.

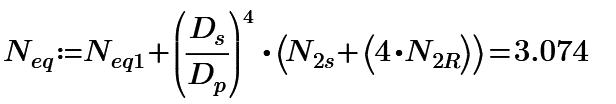

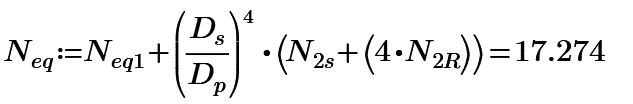

The following equation can be used to calculate equivalent number of sheaves:![]() . The value for

. The value for ![]() can be selected from the table below. For example, if we look at the last V-groove that was considered in the endurance factors above, 35°, we would select 18.5 as the value for

can be selected from the table below. For example, if we look at the last V-groove that was considered in the endurance factors above, 35°, we would select 18.5 as the value for ![]() .

.

The ![]() is the relationship between the traction sheave and the average deflector sheave. The

is the relationship between the traction sheave and the average deflector sheave. The ![]() is the number of deflectors with simple bends, and the

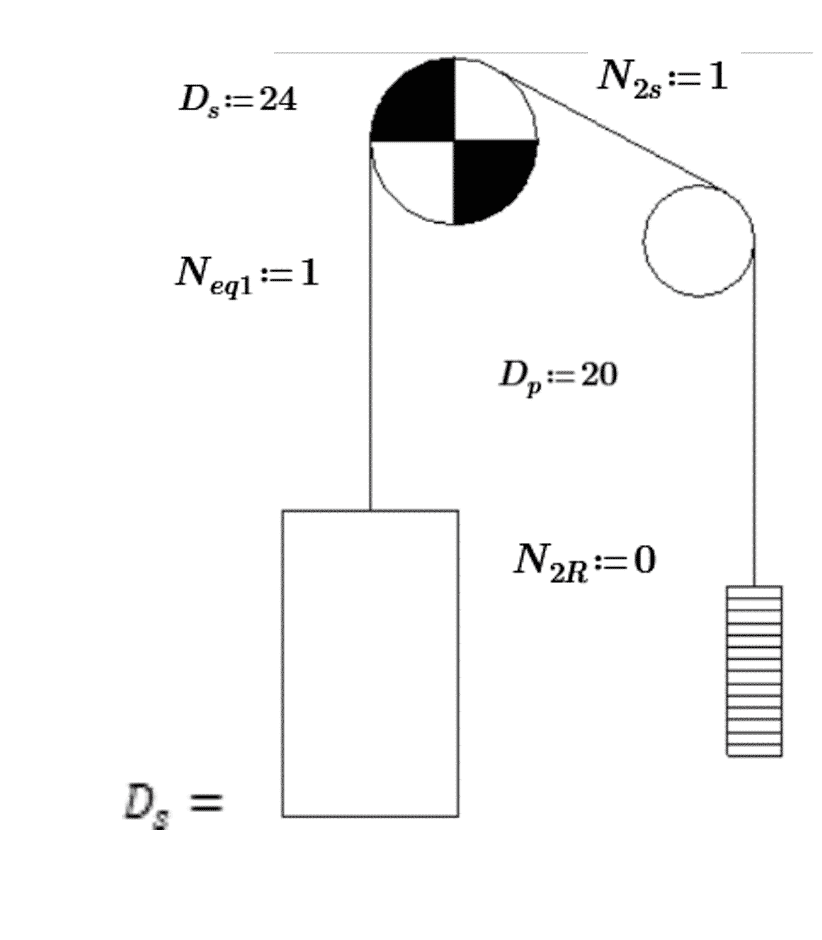

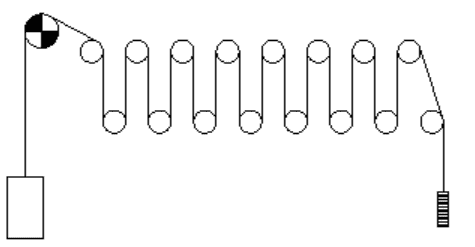

is the number of deflectors with simple bends, and the ![]() is the number of deflectors with reverse bends. This method is easily shown with an example using the simple system below.

is the number of deflectors with reverse bends. This method is easily shown with an example using the simple system below.

Consider the following variables:

Traction Sheave is 24 in. round U-groove

Deflector Sheave is 20 in. ![]() since we are equating to equivalent round U-groove.

since we are equating to equivalent round U-groove.

Traction sheave is 24 in. ![]()

![]() Only one deflector sheave, so there is no need to average. If there were multiple deflector sheaves with different diameters, one would simply take the average as the

Only one deflector sheave, so there is no need to average. If there were multiple deflector sheaves with different diameters, one would simply take the average as the![]()

![]() . There is only one deflector with a simple bend

. There is only one deflector with a simple bend

![]() . There are no deflectors with Reverse bends.

. There are no deflectors with Reverse bends.

If we plug these values into the appropriate portion of the equation, the calculation yields a result of 3.074 equivalent sheaves. One may ask, “If the drive sheave and deflector are both round U-grooves, why was the results not 2?” The reason for this is the deflector sheave is smaller, or tighter, with a bend that takes place at the deflector. One sees this in the portion ![]() of the calculation and can see the ratio of the large traction to smaller deflector yield 1.074 additional bends, when considering the bends on the larger traction sheave. If the deflector were the same diameter as the drive, this would have been the case.

of the calculation and can see the ratio of the large traction to smaller deflector yield 1.074 additional bends, when considering the bends on the larger traction sheave. If the deflector were the same diameter as the drive, this would have been the case.

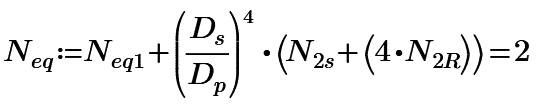

Now, let’s consider the same installation shown with the same 24-in. diameter traction sheave and 20-in. deflector, but with the traction sheave having a 105° undercut.

From the table at left, a 105° undercut U-groove has a ![]() . Another way to think of this is to consider one trip through a 105° undercut U-groove is the equivalent of 15.2 trips though a round U-groove.

. Another way to think of this is to consider one trip through a 105° undercut U-groove is the equivalent of 15.2 trips though a round U-groove.

Now, the calculation yields:

So, what one would look at and say it clearly only has two bends in the system? Because of the geometry of the groove and the smaller deflector pulley are equivalent to a system with full-round U-grooves made up of a traction sheave and 16 additional deflector sheaves, for a total of just over 17 equivalent bends per trip as represented above.

Lastly, both of these methods reflect the accumulated damage to the rope or, in other words, reflect the reduction in lifetime caused by these aggressive grooves. If we were to compare the factors of the two differing methods of calculation of the effect of the groove on the rope, we would see that they are basically in agreement. Simply multiply the Feyrer ![]() factor by the corresponding equivalent sheave for a given groove profile, and the results will yield 1. See Table 1.

factor by the corresponding equivalent sheave for a given groove profile, and the results will yield 1. See Table 1.

|

Groove |

fn3 |

Equivalent Sheaves |

Compare |

|

Round Groove r/d = 0.53 |

1.000 |

1.00 |

1.00 |

|

Undercut U-Groove 75° |

0.400 |

2.50 |

1.00 |

|

Undercut U-Groove 80° |

0.330 |

3.00 |

0.99 |

|

Undercut U-Groove 85° |

0.260 |

3.80 |

0.99 |

|

Undercut U-Groove 90° |

0.200 |

5.00 |

1.00 |

|

Undercut U-Groove 95° |

0.150 |

6.70 |

1.01 |

|

Undercut U-Groove 100° |

0.100 |

10.00 |

1.00 |

|

Undercut U-Groove 105° |

0.066 |

15.20 |

1.00 |

|

V-Groove 35° |

0.054 |

18.50 |

1.00 |

|

V-Groove 36° |

0.066 |

15.20 |

1.00 |

|

V-Groove 38° |

0.095 |

10.50 |

1.00 |

|

V-Groove 40° |

0.140 |

7.10 |

0.99 |

|

V-Groove 42° |

0.180 |

5.60 |

1.01 |

|

V-Groove 45° |

0.250 |

4.00 |

1.00 |

Table 1

Does this mean one should not use the various V-grooves or undercut U-grooves in their system? That is not the point of this information. The main point is that there are many things that must be considered when deciding how a system is to be designed, and what can be and should be expected out of a given configuration. If the benefit of more space in the building outweighs the additional cost of ownership, or the reduction in energy consumption outweighs the additional maintenance, then the decision was made for the right reason. There is one final thing to understand when looking at the effect that the groove has on the ropes, and that is, all ropes are not equal. This may be better said that all rope types are not the same.

When thinking back to the large D-to-d machines, where the ropes were running in a full-round U-groove, standard 8×19 ropes performed well and lifetime was not an issue. With today’s 40:1 ratios of traction sheaves to rope diameter, combined with the higher pressures generated from the aggressive groove, our only recourse is to use a high-performance (HP) rope design. These would be an independent wire rope core (IWRC) or a parallel wire rope core (PWRC). Both HP designs are produced in full steel as well as mixed-core, meaning the core is either a combination of steel and polypropylene, or steel and sisal. When it comes to the selection of which HP rope to use, there are a few points to keep in mind. First, there is not a single design that is appropriate for all installations. Both IWRC and PWRC ropes have their unique advantages and disadvantages. Understanding this will aid in selecting the best rope for a particular installation. Secondly, no rope, even a high-performance rope, is going to reverse the effects smaller sheaves and aggressive grooves have on the lifetime of a rope. What it can do is provide “better” results or “better” lifetime than that of a standard 8×19 rope, if the proper HP rope is selected. When one looks at the slightly higher cost of an HP rope versus the cost of changing the less-expensive 8×19 — multiple times, in some cases — it’s not hard to see the benefit of the higher-performance ropes.

If we understand the cost versus the benefit, we can be confident in the decision we are making. Whether it’s in maintenance planning, cost of operation calculation or — in the best case — specifying what is desired up front so that the best decision can be made, the old adage holds true: “Knowledge is Power.” Knowing what you have, what you are getting or what you are providing should be the goal for all.

Get more of Elevator World. Sign up for our free e-newsletter.