This Product Spotlight looks at a unique and helpful product that was created by accident.

Stingl was founded in 1979 by Leonhard Stingl with “great entrepreneurial spirit and decades of sales and design experience in the lift industry” and is now known as an expert in fastening technology and shaft equipment, as well as a one-stop solution supplier of components in lift construction. Stingl GmbH, based near Heilbronn, Germany, serves customers in Germany, while Stingl Systems GmbH operates the international business. Beyond its standard products, the company offers custom, practical solutions from needs analysis and special construction to just-in-time construction service.

As a new offering to the vertical-transportation (VT) industry, Stingl developed and launched the oil- and chemical-binding agent Zauberwatte® — which means “magic cotton wool” — to combat contaminations.

The product was originally launched in 2015 by a company from Eastern Germany but was not intended for the lift industry. The magic cotton floss was not purposely developed but was the result of an “accident” in production, according to Dirk Schoeffler, Stingl managing director. The first applications were for the firefighting industry due to the product’s ability to absorb critical substances while also being water-repellent.

Together with partner company Universale Produkt — und Servicegesellschaft mbH from Aschau im Chiemgau, Germany, Stingl developed special forms of the Zauberwatte for application in the elevator and escalator industry. Universale CEO Martin Reichl used to work in the lift industry as a service technician. He knew about the common problems with oil spilling and the time-consuming cleaning in all relevant areas of the lift (cabin, shaft, machine room, etc.). Adding the product was an easy next step, as Stingl had been offering oilers and oil collectors for many years. Historically, conventional oil-binding agents were more difficult to handle and more time consuming to dispose of, and the new product remedied this.

Product Details

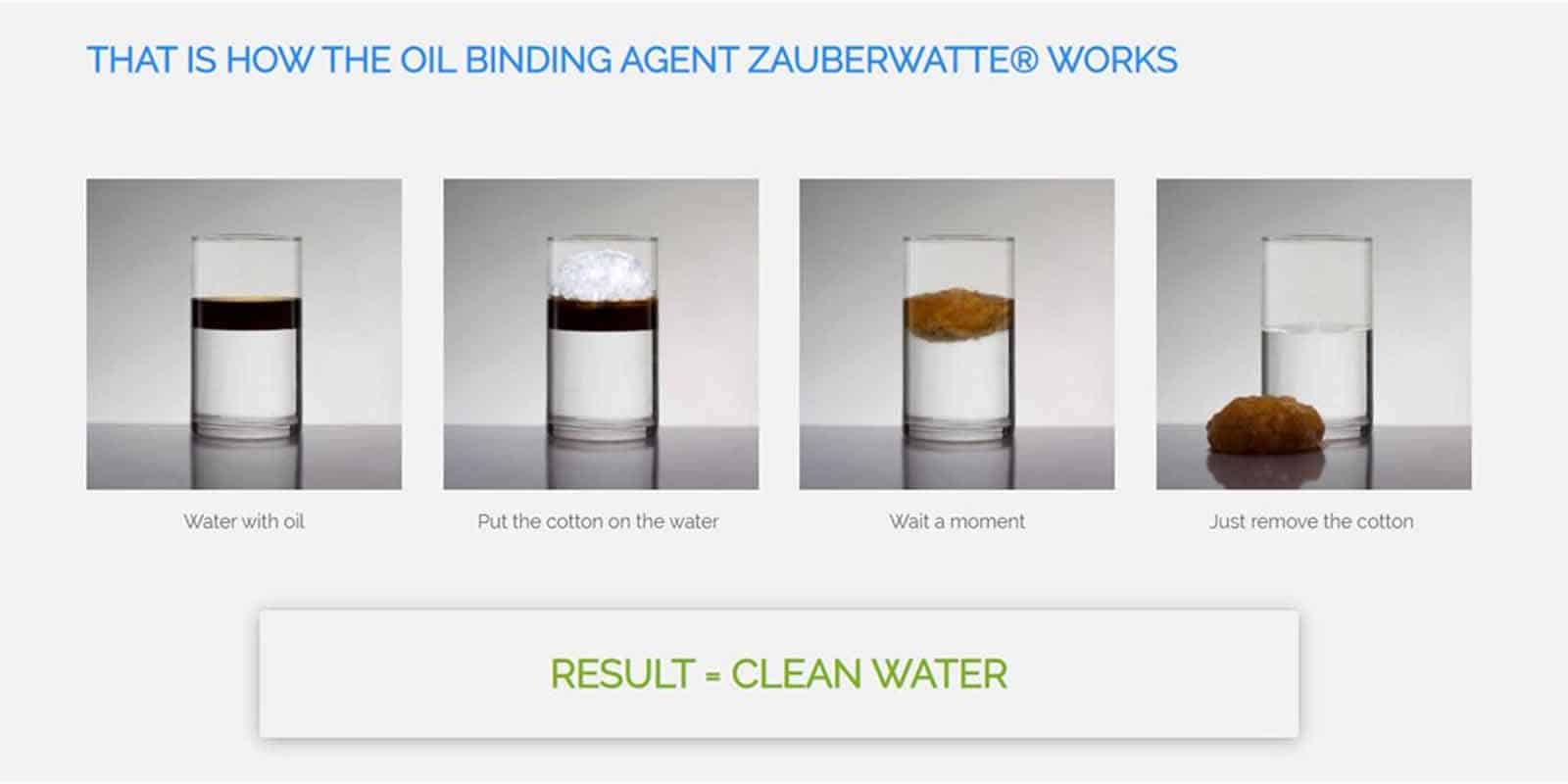

Zauberwatte absorbs everything that is lighter than water. Zauberwatte binds contamination from oil and chemicals within seconds, can be removed without leaving any residue and can then be recycled. Just 1 kg of Zauberwatte is enough to absorb 6 l of oil, which is 30% more than any other oil-binding agents available. Place Zauberwatte on the oil contamination, wait for a short period and simply remove it.

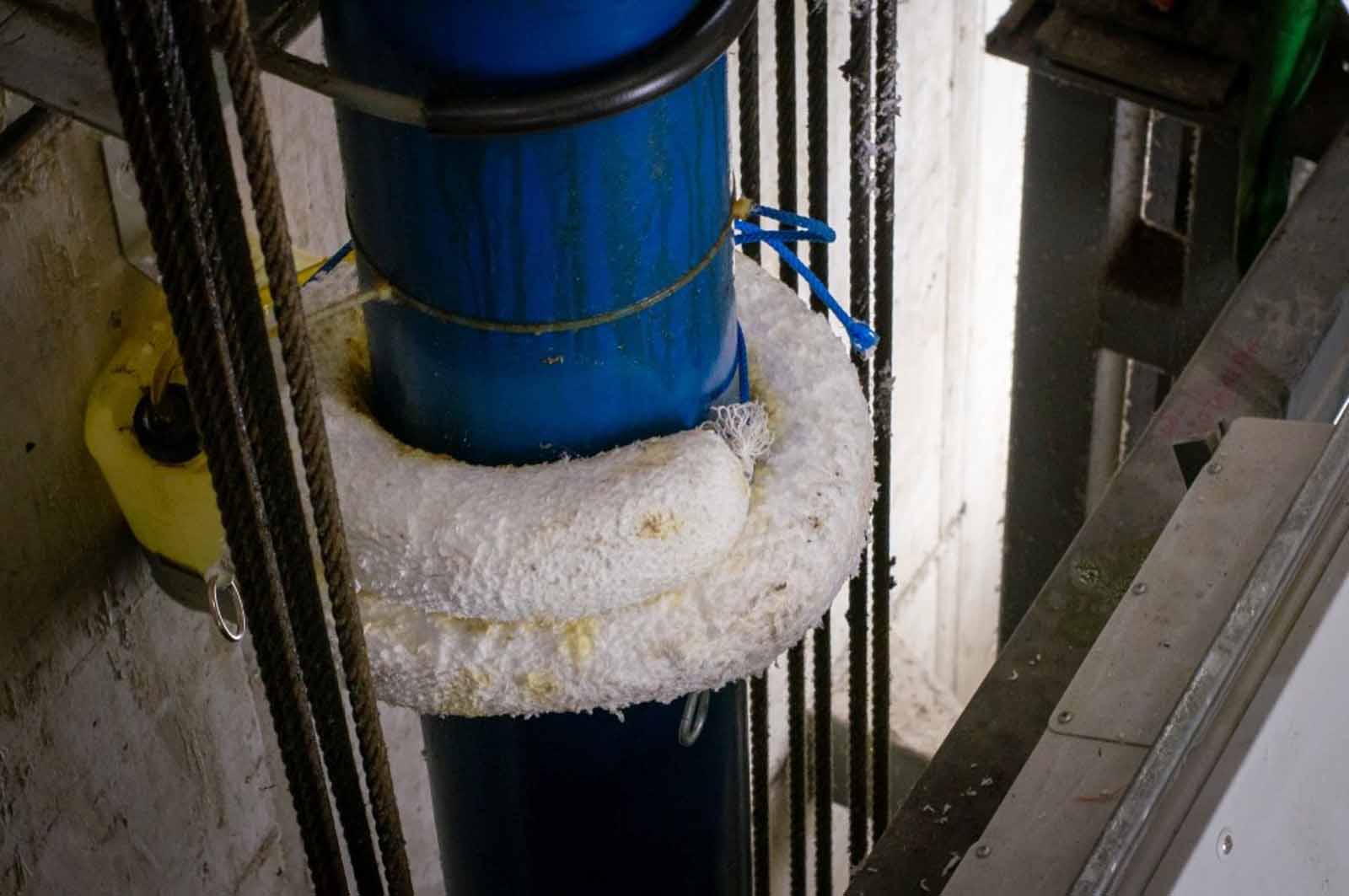

This product has been adapted for use in the elevator industry, e.g., during maintenance jobs. The Zauberwatte pad is a smart addition to any oil collection container and, thus, a real relief for lift maintenance. There is no spilling when the pads are removed and disposed of, which saves time cleaning the pit. This also applies when using the net sleeves on hydraulic lifts. The cloth wipes work well for smaller incidents of oil spilling, be it on the car roof or in the pit or machine rooms. The wipes can be put in service cars without requiring major space.

Other special product forms, like bigger mats, allow for dealing safely and efficiently with water-oil scenarios in the pit, e.g., after severe weather conditions. The mats are simply thrown into the pit with the oil-water mix. After a few minutes, the mat has absorbed the oil and can be removed, and clear water can be pumped out of the pit. This is a major advantage over the common disposal of an environmentally critical mix of oil and water.

Zauberwatte was the winner of the European Inventor Award 2017 and is certified by DEKRA Umwelt GmbH.

The advantages:

- Quick and clean removal of used oil from containers

- Easy transport of new and used Zauberwatte pads in service boxes

- Container cleaning approximately 80% quicker than before

Get more of Elevator World. Sign up for our free e-newsletter.