“New York, New York, a Eleva’ Town”

Mar 1, 2018

Looking at NYC’s vertical-transportation heritage through the unique Park Row Building

The 1944 Broadway musical On the Town featured the song “New York, New York” (music by Leonard Bernstein with lyrics by Betty Comden and Adolph Green). The lyrics include the well-known phrase “New York, New York, a helluva town.” (In the 1949 MGM movie version, “helluva” was replaced by “wonderful” to satisfy censors). This background is offered as an explanation (with apologies to Bernstein, Comden and Green) for the above title. The origin of this song-inspired article was the December 15, 2017, issue of The New York Times that featured “Riding a Time Capsule to Apartment 8G” (written by Andy Newman with photographs by Thomas Prior). This lengthy article highlighted the diversity and unique characteristics of New York City’s (NYC) existing stock of “vintage” elevators. This prompted the desire to examine two decommissioned elevators in the Park Row Building in Lower Manhattan, which I had the opportunity to visit and photograph in March 2017. (This building is also featured in “Elevator Telephony,” ELEVATOR WORLD, November 2016). These machines, designed and built by Sprague Electric Elevator Co. in the 1890s, are examples of a unique type of drum machine manufactured in NYC in the late 19th and early 20th century. They also serve as a reminder that the city — in both its “living” and “dead” examples — possesses a “helluva” vertical-transportation heritage.

The Park Row Building (the tallest building in the world from 1899 to 1908) was designed by Robert H. Robertson and built in 1896-1899. The building was best known for its use of 10 Sprague vertical screw-driven electric elevators, which were versions of the horizontal screw-driven electric machines designed by Frank Sprague and Charles Pratt. These machines initially served as the building’s primary elevator system. (For a discussion of these systems, see my book From Ascending Rooms to Express Elevators: A History of the Passenger Elevator.) However, the vertical machines proved as problematic as their horizontal predecessors in their operation, and they were replaced in 1913/1914 by Otis traction machines.

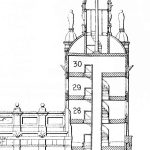

In addition to the primary passenger elevators, Sprague also supplied the building with a sidewalk elevator (“The Sidewalk Elevator,” EW, June 2004) and two drum machines that served the building’s twin seven-story towers that grace the main façade (Figure 1). These machines ran from the 26th to the 29th floor (four stops). A combined elevation/section drawing published in Engineering News in 1896 illustrated one of the tower elevator shafts. Interestingly, this drawing made no allowance for a penthouse or machine room. This could be read as evidence that the original design relied solely on the circular stairway for movement between the tower floors, with the elevators added later, perhaps during construction. (Figure 2 illustrates an approximation of the machine-room location.) The presence of the circular stairways resulted in circular shafts and cars, and the quality of the original open metalwork shaft doors remained evident, even as they were being readied for demolition (Figure 3).

The tower elevators were “Type V” drum machines, which were described by Sprague as its “medium-sized machine” and “the one best adapted for ordinary requirements.”[1] These machines were powered by a two-pole, 6-hp electric motor. Sprague described this motor design as capable of carrying “heavy overloads without sparking,” while maintaining “a constant speed under variations of loads.”[1] The elevator had a 2500-lb. capacity, with a maximum operating speed of 180 fpm. The machine employed a worm-gear connection between the engine and winding drum, with a steel worm gear turning a bronze worm wheel. A 1904 Sprague catalog showed the machine and controller mounted on a cast-iron bedplate, approximately 4 X 5 ft. in size, which was characterized as “an unusually compact arrangement” (Figure 4).[1]

The Park Row Building tower elevators were designed to carry an average load of 1200 lb. (the cars had a four-foot diameter) at a top speed of 110 fpm with a total rise of 33 ft., 3 in. Their installation differed from the catalog depiction in that the controllers were not located on the machine bedplate (Figure 5).

A feature evident in both the catalog and installation photographs was an “automatic control mechanism,” which was also known as a “floor controller” (seen to the left of the machine controller in Figure 4; a detail is shown in Figure 6). Otis engineer George H. Malcolm later described this device as follows:

“The Floor Controller, a device by which the elevator is automatically stopped at the desired floor, is provided with arms corresponding to the number of floors, which are caused to rotate by means of a chain driven from the winding drum, and therefore at a proportional speed to that of the latter, thus maintaining a definite relation to the position of the car in the hatchway. By means of certain contacts arranged in series with the Reversing Switch, an operating circuit is established when a button is pressed and is not broken until the Floor Controller assumes a position corresponding to the floor desired.”[2]

The tower elevators featured push-button control in the cars. In 1899, with the absence of automatic leveling devices, floor controllers were used on drum machines to ensure cars stopped level with the landings.

The motor controller employed one primary and two secondary solenoids, and was described by Charles Pratt in 1899 as “entirely electric” in its operation:

“. . . the making, braking, reversing and circuiting through a resistance when stopping being accomplished by the two solenoids on either side of the main solenoid. The rheostat solenoid in this controller is direct lifting against gravity and is governed by an adjustable air dash-pot in the interior of the coil. The contact brushes are carried on the end of the plunger, making contact with the rows of segments on either side. The movement of this plunger is about 10 in., and its rapidity of movement is easily varied by the air dash-pot from 1-5 s. as desired.”[3]

The Sprague catalog provided additional information on the controller’s operation:

“The moving parts of the controller are the two circuit breakers, one on either side, and the rheostat regulator in the middle. The latter is lifted by the action of the solenoid when the current is admitted to the motor, and, in its ascent, it cuts out the starting resistance step by step, giving a gradual and even acceleration and keeping the current low. When the current is shut off, the regulator returns by gravity to its original position, and the elevator cannot be started until all of the resistance is again in the armature circuit.”[1]

One of the tower elevator controllers revealed traces of past elevator-maintenance personnel with the notations “up” and “down” added to identify the functions of the secondary solenoids (Figure 7).

The rarity of these machines is indicated by the fact that the catalog’s listing of “some notable installations of Sprague elevators” referenced only 122 machines in NYC. While, admittedly, this was a partial or selective list, when compared to the number of elevators inspected by building officials in 1904 (the year the catalog was published), 2,830, the opportunity to examine these machines was the equivalent of finding a needle in haystack. This “find,” of course, prompts a question regarding what other treasures — working or idle — remain to be discovered in NYC, which is, of course, “a eleva’ town.”

Acknowledgement

This opportunity was made possible by the generosity of Donald Friedman, PE (Old Structures Engineering, PC), who facilitated your author’s visit to the Park Row Building.

- Figure 1: “Elevation/Partial Section Drawing,” Park Row Building (“The Park Row, 30 Stories High, New York,” Building Engineering News, October 8, 1896)

- Figure 2: “Tower Section,” illustrating location of elevator machine room, Park Row Building

- Figure 3: Exterior of circular elevator shaft, Park Row Building

- Figure 4: Sprague Type “V” elevator[1]

- Figure 5: Park Row Building, Sprague Type “V” elevator

- Figure 6: Park Row Building, Sprague Type “V” elevator floor controller

- Figure 7: Park Row Building, Sprague Type “V” elevator controller

References

[1] Sprague Elevator Co. “Sprague Electric Elevators,” NYC (1904).

[2] George H. Malcolm. “The Automatic Residence Elevator,” Architects’ and Builders’ Magazine (August 1909).

[3] Charles R. Pratt. “Elevators,” Transactions of the American Society of Mechanical Engineers, Vol. 20 (1899).

Get more of Elevator World. Sign up for our free e-newsletter.