In this Readers’ Platform, your authors from Chicago-based Colley Elevator explain how a simple upgrade can improve customers’ bottom line.

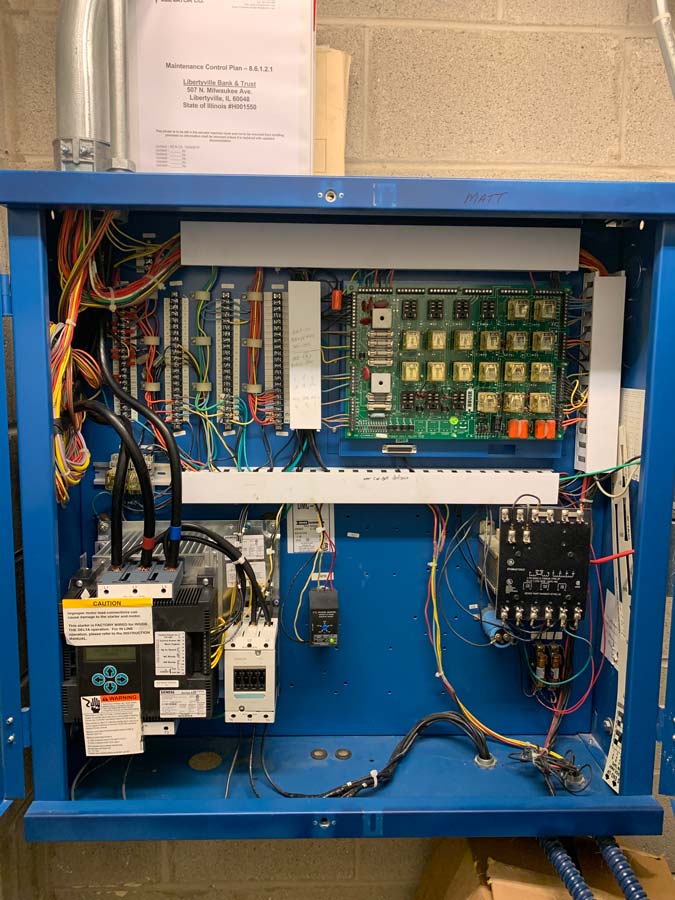

Chicago-area building owners and managers often have questions about their elevators, but when they turn to Colley Elevator Co., we stress that an elevator is a costly machine and a capital building asset. Aside from installation, there are costs for operation and maintenance, as well as decommission and removal. When a facility manager inherits an elevator, it is for the long haul. A few sentences added to the code long after the original installation could mean requirements for newly added safety enhancements, controller capabilities or custom-designed fixtures.

Thankfully, code changes are rare, and, when they do happen, most building owners understand they need to “grin and bear it.” No matter how painful, the cost must be absorbed for the elevator to continue operating, without violations, to serve its passengers.

We at Colley often try to stress component upgrades. Though some are not required by code, they can pay dividends in the long run by extending the life of the equipment. When performing an onsite examination of existing installations, we often see the opportunity for component upgrades unrelated to current code mandates. The most common of these is the potential to upgrade to a solid-state motor starter.

Solid-State Motor Starters

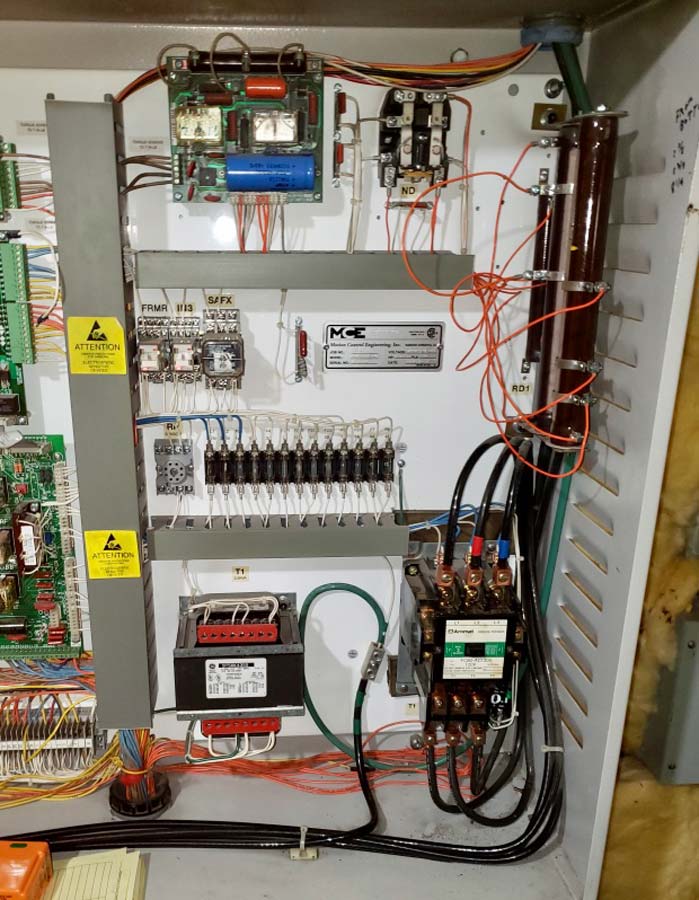

When a customer asks what they can do to improve the reliability or performance of their equipment without performing a full modernization, the most common recommendation is a solid-state (“soft”) starter. Soft starters control the influx of current to the motor upon startup, allowing a soft, gradual climb to full amperage — hence, the name. This relatively inexpensive addition has a variety of benefits.

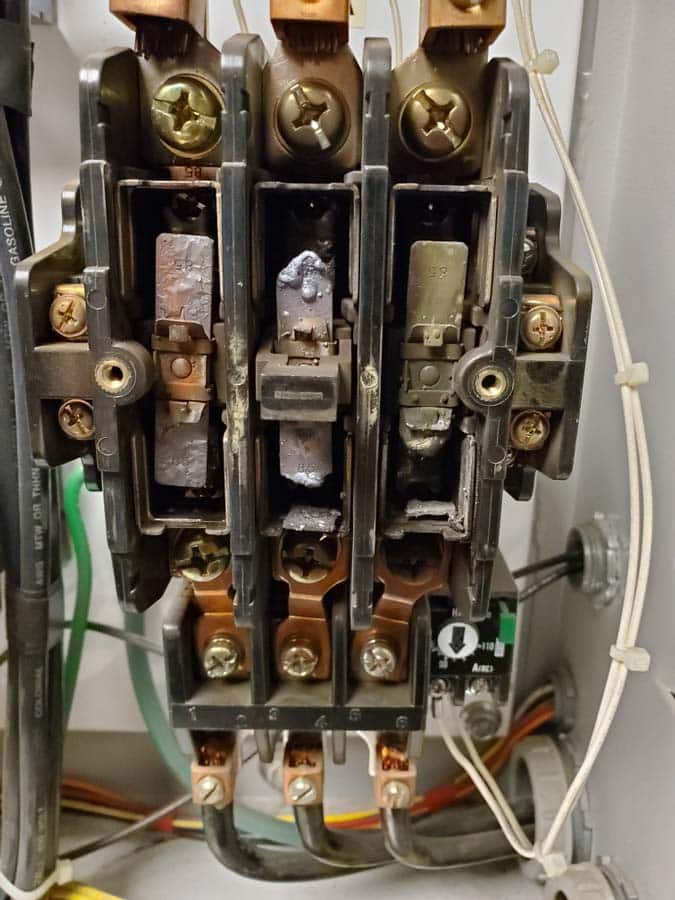

Soft starters have become the go-to choice in upgrading from the old electromechanical, or wye/delta motor starter contactors once standard on all hydraulic elevators. Electromechanical starters are considered yesterday’s technology, and, although they can exhibit an extended lifecycle when properly rated and maintained, we have seen too many fail. When they do, their repairs often cost more than a soft starter retrofit.

The controller’s original copper motor’s starting contacts create multiple points of failure that can deteriorate or weld due to wear or power issues. Upgrading from a mechanical-type hydraulic pump motor or generator starter ensures no coils or electrical contacts will fail. Additionally, having fewer mechanical parts often leads to fewer service disruptions. The best modern soft starters can even record and display fault codes. When properly installed and programmed, they provide the time and day of fault occurrence.

As a result, the time for troubleshooting can be drastically reduced, which often can lead to the identification of motor failure sources outside the controller. We typically see external sources in the form of incoming feed disruptions, such as those caused by the power company, brownouts and Mother Nature. For example, one of our customers with a five-stop hydro was having intermittent controller issues. Instead of trial-and-error troubleshooting on an array of contactors, we were able to identify intermittent power issues due to electrical service interruptions. The time saved by quickly isolating the source of the error meant a greatly reduced service invoice to the customer.

Solid-state starters also provide motor protection with reverse-phase detection, three-phase voltage monitoring, voltage comparisons and motor winding current. In this way, they are similar to another set of in-line fuses. Soft starters can not only protect the motor from sudden power surges, but also prevent everyday wear and tear. In an electromechanical motor starter, starting current can be seven to 10 times higher than a high-speed running current and may even reach 10-15 times more in higher-efficiency motors. The ability to adjust the starting and stopping current reduces the strain on mechanical components, resulting in improved overall performance and leading to longer motor life.

Additionally, an upgrade to solid-state starters can offer a psychological benefit for the building’s passengers. This is realized when the upgrade eliminates starter noise or the dreaded “bang” when an older unit starts and runs. The upgrade also can improve ride quality and perception of safety. Giving riders peace of mind helps reduce nuisance issues (e.g., “water cooler talk”), which, in turn, can reduce callbacks.

Convincing the Customer

As longtime industry mechanics, we need to envision ourselves in the customer’s position. When we discuss upgrades, we should imagine it’s our money that’s being spent. We firmly believe that a good contractor is the customer’s partner and advocate who helps them maximize their investment and have it pay dividends for years to come.

Get more of Elevator World. Sign up for our free e-newsletter.