Power Play

Sep 1, 2017

How to modernize your existing elevator to achieve net-zero energy and meet modern urban mobility and sustainability challenges

Approximately 40% of total U.S. energy consumption was attributed to buildings last year, with elevators accounting for as much as 10% of that. Elevators consume 5 billion kWh per year, costing roughly US$500 million. Significant strides have been made to improve elevator efficiency. In an attempt to control the speed of elevators in the 1970s, for example, motor-generator sets that took AC power and created a DC current, which at the time was the only way to control the speed of a motor, were used. But, it wasn’t about energy efficiency; it was simply about improving an elevator’s performance.

In the 1990s, AC drive technology eventually advanced to a point where an elevator’s energy consumption was cut in half, inspiring elevator companies to reexamine how they could further improve the energy efficiency of their units. It was during this critical period that the energy efficiency of elevators was thrust into the spotlight.

A Powerful Movement

During this time, energy consumption was once again cut in half through improved regeneration processes. Instead of converting the regenerated energy into heat and dissipating it in the machine room, manufacturers were applying different transformers that cleaned the energy and put it back into the building, which helped contribute to nearly 40% of the energy being fed back into the structure. Elevators had become small energy consumers within a building, but the opportunity was there to do more. Enter net zero.

The Fraunhofer Center for Sustainable Energy Systems sought to [find out how much of a difference a net-zero elevator system makes] when it modernized an elevator in a 100-year-old Boston office building.

Approximately 10 years ago, manufacturers started looking for ways to make their new elevators net-zero energy units. While that was an important step toward increased sustainability in the built environment, the problem was that it was too narrowly focused. The number of new buildings added to the global total each year is less than 2%. In the U.S., more than 70% of all buildings are over 25 years old, meaning only a small fraction of the elevators installed worldwide were an option.

Around the time net zero was being introduced on elevator systems, a new certification that would redefine environmentally friendly buildings was being ushered in. The Living Building Challenge, created in 2006 by the International Living Future Institute to promote the most advanced sustainability efforts utilized to achieve zero-energy buildings, is a green building certification program that can be applied to both new construction and modernizations. This helped inspire the idea of modernizing elevators with net-zero energy systems, but the challenge was how to do it.

Getting to Net Zero

Getting to net zero requires a series of steps that diminish the energy consumption of every part of the elevator system. This process eliminates inefficient legacy components, enabling the owner to achieve the lowest energy consumption mode potential (i.e., the smaller the energy footprint, the smaller the amount of energy that has to be offset with solar or other alternative energy sources). For example, without optimizing the energy footprint, solar panels used to consume a significant amount of roof space, but today, those solar panels can be installed within the footprint of the elevator shaft itself, making it more practical and cost–feasible. The main components of an elevator system that can be optimized are:

- Controller

- Drive

- Machine room

- Motor

- Dispatching

- Lighting/ventilation

Regenerative drives recapture energy when the elevator is in motion, taking the energy regenerated during braking and, instead of dissipating it as heat in the machine room, cleaning it and sending it back into the building to be consumed by other devices. Often, machine-room cooling is never considered, because it is technically not part of the elevator system, but the dedicated AC cooling unit typically required can be eliminated or significantly reduced in size when regenerative technology is used.

Getting to net zero requires a series of steps that diminish the energy consumption of every part of the elevator system.

Net-zero energy is also achieved through the inclusion of a smart/learning controller with deep-sleep or hibernation mode, and automatic power-down of the cab lighting and fan circuit when the elevator is inactive. LED cab lighting is also an important part of a net-zero energy elevator system. Due to code requirements, many vintage elevator systems did not permit the lights to turn off, draining energy resources. In a low-rise building, for example, a typical elevator consumes more energy from the lighting system than it does actually moving people. Simply replacing halogen and incandescent bulbs with LED lights can deliver the performance of a fluorescent bulb but with 10-15 times the lifespan. LED lights should also be incorporated as the backlights of buttons.

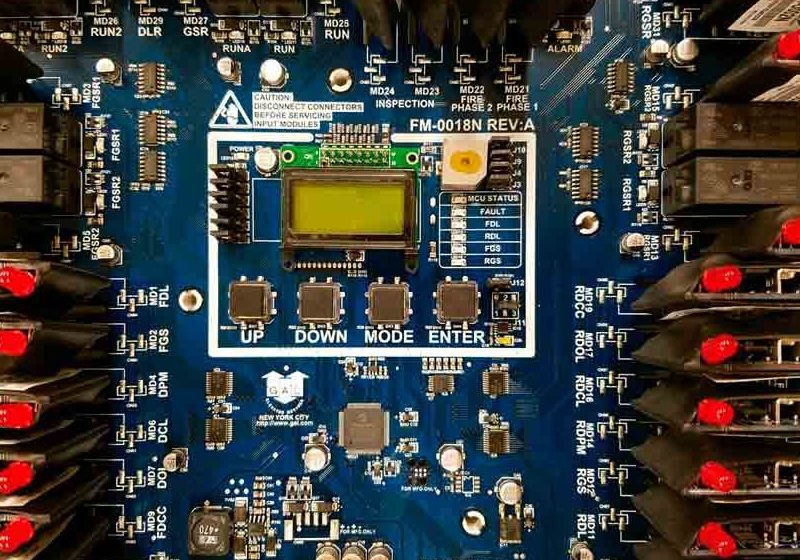

Smarter and more-efficient technology allows elevators to turn the lighting and fan off based on elevator trends, using such data as the last time a button was pressed, or use a two-speed fan to circulate fresh air through the cab based on occupancy. Another aspect of a net-zero elevator system is switching from relay to microprocessor controls on the board, which reduces the amount of energy and energy losses by having more integrated circuits per area of the printed circuit board, making the controller and circuitry more energy efficient. In addition, elevator companies developed special AC motors with variable-frequency drives that are designed for lower RPMs required by elevator systems, thus eliminating the need for reduction gearing.

Passing the Test

Net-zero energy elevator systems are great in theory, but how much of a difference do they really make? The Fraunhofer Center for Sustainable Energy Systems sought to answer that question when it modernized an elevator in its 100-year-old Boston office building with a net-zero solar energy system. Fraunhofer installed a 3.75 kW rooftop solar photovoltaic (PV) array that fit within the elevator footprint. Incorporating many of the energy-efficient features referenced earlier with a low-to-medium activity profile, the elevator used roughly 8 kWh per day. The solar PV array produced 11 kWh per day, which translated to an energy surplus of 45%. Even in a high-usage scenario where usage is doubled on business days, net-zero energy is still projected with the same

solar array.

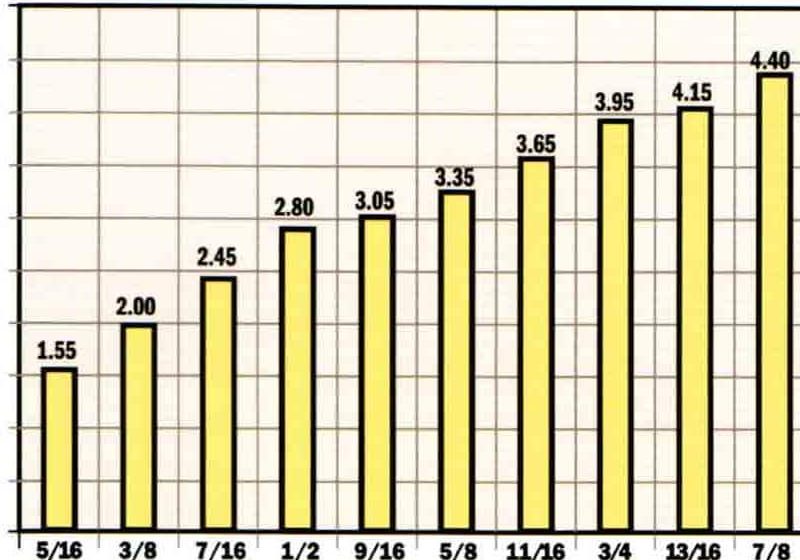

Fraunhofer then measured elevator power draw in another office building for several years, using different configurations compared to the one year of the net-zero energy elevator. Upgrading the elevator controller reduced standby power draw by more than 75%, from 400 to 100 W. Meanwhile, installing automatic powering down reduced cab standby power by 90%, from 90 to 9 W.

More people are seeking to ride the net-zero energy wave as the number of certifications being applied for continues to increase, and conferences like the Global Energy Forum, where people can learn more about net-zero or net-neutral buildings, become a priority. Twenty-five years ago, many people may have laughed at the thought of an elevator contributing to a net-zero building, but many also thought a sideways-moving elevator was impossible.

Get more of Elevator World. Sign up for our free e-newsletter.