Technology Is Key

Aug 5, 2022

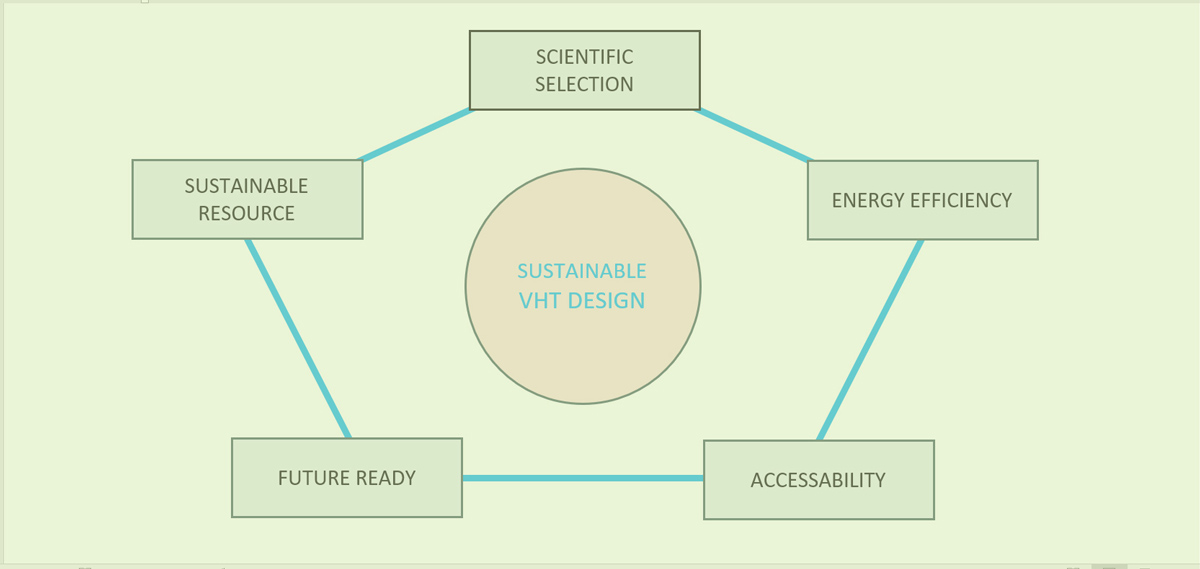

Your author talks about a strategic approach to better VT design to enhance sustainability.

Of the 17 United Nation’s Sustainable Development Goals, three are very prominent and relevant to the vertical-transportation (VT) industry. They are:

- Goal 7, Affordable and Clean Energy. Energy is the dominant contributor to climate change, accounting for approximately 60% of total global greenhouse gas emissions. While this goal is specific in its commitment to ensuring access to affordable, reliable and modern energy services, it also targets improvements in energy efficiency.

- Goal 11, Sustainable Cities and Communities. Rapid urbanization stresses natural resources. It also creates parity between communities. Half the world population lives in cities today. This goal promises to make urban habitats safe, inclusive, resilient, sustainable and affordable. It pays special attention to persons with disabilities and the need for accessible infrastructure in an inclusive society.

- Goal 12, Responsible Consumption and Production. Consumption drives production and vice versa, which, in turn, drives the global economy. This goal targets the use and scientific management of natural resources. Material-efficient strategies, such as a minimalistic approach to design and material recycling, are encouraged. Responsibly sourced materials that do not damage the environment are key.

Strategies

Selection

Good people flow/circulation is critical for a building to meet the very purpose for which it was built. A methodical and scientific approach ensures optimum design and material usage. Circulation in buildings is complex, and VT systems should be designed to meet passenger traffic demands. Any other approach may lead to either under designing or over designing a VT system. Either way, the impact is most likely irreversible. Even if it is reversible, it would be an expensive undertaking that wastes time and resources and diminishes good will. Simulation tools could provide closer-to-reality scenarios for decision making. Taking the advice of experts is recommended, since they can provide guidance on all aspects of VT systems, including regulatory requirements.

Efficiency

VT system efficiency is not just about handling passengers, but about providing the right equipment. Gearless, permanent-magnet synchronized motors are compact machines that are very energy-efficient and use fewer resources in manufacturing. Elevator manufacturers have designed compact gearless machines and other equipment traditionally housed in a machine room to fit into the hoistway, eliminating the requirement for a separate machine room on top. Machine-room-less (MRL) elevator systems enable less heat dissipation and energy consumption compared to larger, previously used systems.

Gearless traction MRL elevators provide superior performance, as they are significantly reduced in size, including their power cables, with a compact design that reduces the cost and environmental concerns associated with conventional equipment that consists of large geared machines housed in separate machine rooms.

Door motors can also be gearless, and are designed to enter standby mode or efficiently reduce or remove power consumption when not in use. They can be programmed for variable door-open and -close times. Regenerative drives are among the most significant innovations in energy-efficient elevator technology. An elevator moving up with a light load and coming down with a heavy load generates more power than it consumes, which results in a considerable amount of energy loss as power is lost in the form of heat through resistors installed in the elevator drives. Regenerative technology can also be applied to escalators, which can, additionally, be outfitted with power-saving features such as automatic slowdown or shutdown when traffic is light or nonexistent.

Additional heating would require cooling, and adds to the cost burden on the building owner depending on the size, duty and number of elevators in a building. The regenerative drive replaces the traditional braking resistor, and can be used alongside the elevator drive. The drive transforms mechanical power into electrical power and pumps it back into the electrical grid, where the energy can be utilized by another elevator or system that requires power. In this way, regenerative drives can save up to 70% of energy and reduce the strain and cost of the heating, ventilation and air conditioning (HVAC) system, eliminating excess heat in a building that would have been otherwise wasted. Thus, this factored energy usage supports an overall efficiency strategy.

Accessibility

An accessible ecosystem is built on the principles of universally inclusive design. The design and composition of the environment is so that it can be accessed, understood and used to the greatest extent possible by all people regardless of age, size or physical ability. This is a civilizational need, irrespective of whether it is mandated as a regulation. Society succeeds when it supports all, regardless of their shortcomings.

While the The Rights of Persons with Disabilities Act, 2016 is very clear on the aspects that must be addressed in ensuring a barrier-free and accessible VT system, the implementation of the same is crucial. Regulatory and licensing agencies seldom insist on compliance. More often, it has been a voluntary action by responsible developers. The compliance should not be viewed as a cost factor or extravagance, but as a responsible provision that ensures a sustainable and inclusive environment for all.

Bare-minimum requirements such as adequate capacity, operating panels with Braille buttons positioned at appropriate heights, announcement systems, handrails, signages and tactile way finders need to be provided without hesitation. These do not cost much. The requirements can be exceeded, but should never be ignored.

Future Forward

Any planned development should consider possible future scenarios. Designs need not be precisely accurate, but should account for potential changes in usage, traffic flow and occupancy — for example, as a result of a population increase. It is prudent for any traffic designer to factor in a minimum variance so a building can handle a given volume of population as time elapses. At the same time, considerations should not be so emphasized that they dent the developer financially or impact resources. This could defeat other strategies, such as energy efficiency and material responsibility.

Control systems that are more contemporary must be understood for their applicability and implemented reasonably. Growth in construction, user profile changes and innovations have transformed the way elevators are designed to work. One such major advancement in elevator control technology is the destination control system (DCS). Elevator manufacturers are designing systems for enhanced speed and safety with advanced high-tech features. DCS is one example. When a passenger presses the button for a specific floor, an indicator directs them to a specific elevator that will take them to their destination faster. The advanced routing allows efficient mobility of passengers, particularly during high-traffic hours. In the same fashion, internet-connected elevators, commonly referred to as IoT, work by sending real-time alerts to building managers about problems, which saves time and money on repairs.

Linear induction motors have enabled manufacturers to design cable-free elevators that allow mobility in horizontal, as well as vertical, direction. These cable-free elevators make the elevator cabs move in linear directions along magnetic rails, which saves energy and reduces the building’s carbon footprint by a significant amount compared to conventional elevators. The costs of such systems are high. But, as time progresses, when volume increases due to demand and more players come into the field, costs are bound to drop.

Other innovative solutions — such as double-deck elevators with pantographs and two independent elevators operating independently in a single shaft — are good modernization options for high-rise, high-volume buildings. Nevertheless, sensible and wise decision-making to objectively identify the best fit for requirements is important.

Resources

Material utilization is a key strategy for any sustainable design. Minimalistic design should not be an unconscious design decision and should not compromise any of the basic design strategies that would alter the very character of the product and render it lifeless.

Elevators should last long. Frequent replacements or modernizations are deterrents to sustainability. What needs to be done is a very important consideration. The solution, though simple, is very strategic: Maintenance is key. An elevator needs care. To prolong its useful life, monitored maintenance at periods determined by the OEM is a must. Repairs and replacements should be carried out on time so the problem does not cascade and affect other components or parts of the equipment. Replacements and modernizations should happen only when the OEM or the service provider is unable to provide support for the equipment with respect to spare parts, non-availability of trained manpower or when more energy-efficient modern technology can provide cost benefits in the short term.

If cost is a major concern, recycled or upcycled elevators and components can be an option. However, the crucial aspect should continue to be safety, code compliance and — above all — energy efficiency. Most steel hardware can be recycled and used after proper refurbishment. However, the controller and all related electronic components, including the prime mover, must be replaced. If a proper standard operating procedure is adopted, recycled or upcycled equipment and components can create their own alternate markets in the lower segment, which is very price sensitive.

Strategic planning and incorporating ideas that help build sustainable, high-performance, energy-efficient, low-impact buildings is the key to a save our planet from deterioration.

Get more of Elevator World. Sign up for our free e-newsletter.