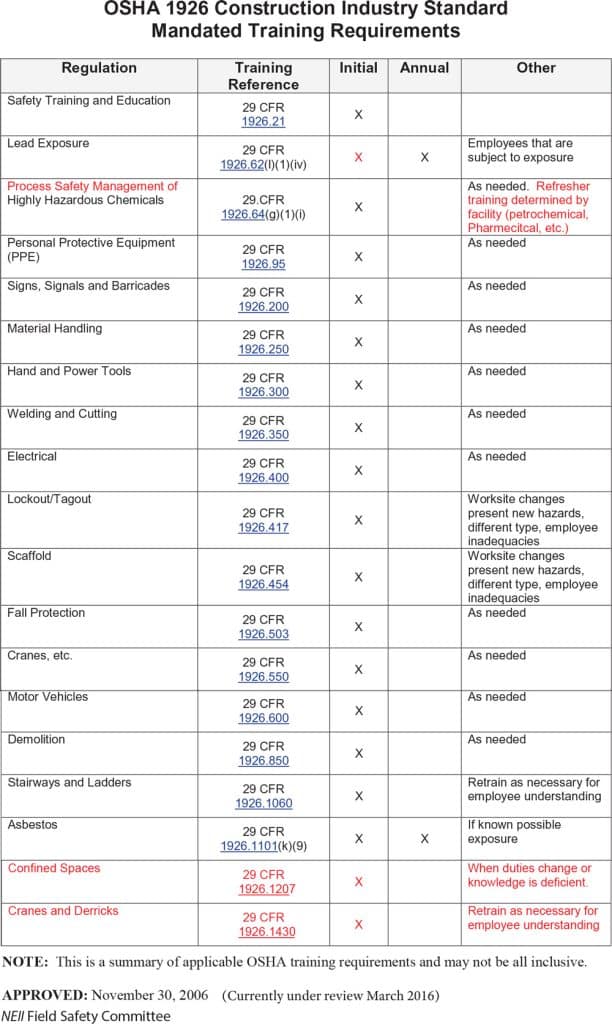

Training-program requirements and how to use NEII®’s matrices for OSHA’s general industry and construction standards

A thorough employee training program is an essential element of every employer’s safety and health management system. First, OSHA’s standards are replete with mandatory employee training requirements. Failure to provide training required by OSHA’s construction or general industry standards exposes an employer to costly OSHA citations. Elevator construction and service companies are no exception and, in fact, can be subject to more training requirements because of the high-hazard nature of the elevator/escalator work environment. Second, one of the few effective defenses available to an OSHA citation is to show that the violation occurred because an employee failed to follow work rules. To do this, an employer must be able to prove the employee was trained in that work rule. Without documented training (remember, if it’s not documented, it didn’t happen!), an employer will be unable to point to an employee’s misconduct as the cause of the alleged OSHA violation.

Keeping track of the myriad OSHA training requirements, and when or how often training must occur, can be an administrative pain. In an effort to help employers stay compliant, however, the National Elevator Industry, Inc. (NEII®), has compiled a set of matrices for OSHA’s general industry and construction standards. These easy-to-use charts describe the regulation topic, the standard imposing the requirement and the frequency required by OSHA.

The general industry standards set forth in 29 CFR Part 1910 (§ 1910) apply to employers engaged in elevator service or maintenance. The training matrix covers the training requirements for such major topics as lockout/tagout (LOTO) (§ 1910.147), electrical safety (§ 1910.332), powered industrial trucks (§ 1910.178) and first aid (§ 1910.151). It is important, however, that employers use the matrices as a starting point for their training programs, because it is intended only to summarize major issues, not substitute for an employer’s own program. When in doubt, get advice from a professional about the specific training obligations associated with the types of work employees actually perform.

For example, the general industry matrix for LOTO states that only “initial” training of an employee is required. Technically, this is true. Under § 1910.147(c)(7), an “authorized employee” must receive training prior to performing hazardous energy control during work. Moreover, as the matrix notes, retraining is required when an employee changes jobs, works on equipment presenting new hazards, a change in procedures occurs or “whenever a periodic inspection under paragraph (c)(6). . . reveals. . . that there are deviations from or inadequacies in the employee’s knowledge. . . .”

When in doubt, get advice from a professional about the specific training obligations associated with the types of work employees actually perform. . . . It is highly possible OSHA would view a typical 5 ft.-deep elevator pit, needing a ladder to access, as a confined space.

What is this “periodic inspection under paragraph (c)(6)?” It is an inspection of the energy-control procedure that must occur “at least annually. . .” What does this have to do with training? The periodic inspection of the energy-control procedure must also “include a review, between the inspector and each authorized employee, of that employee’s responsibilities under the energy-control program. . . .” In other words, an employer must review, or audit, its employees’ knowledge of LOTO procedures at least once a year. In my mind, this review is much more of a training exercise than a bureaucratic checking of boxes. Many employers make this review a key part of their hazardous-energy-control training, which they perform at least once a year as part of an audit process that examines multiple key safe work rules beyond LOTO, such as fall protection, safe hoistway and pit access, and personal protective equipment. Therefore, although the general industry matrix does not have an “X” in the annual column next to LOTO, the reality is that the prudent employer would be wise to do annual LOTO training and audits to comply with the annual obligation to review all authorized employees on their knowledge of the procedures.

The permit-required confined-space (PRCS) standard has also imposed complicated training requirements. Adding to the complication is that OSHA now has adopted a PRCS standard for construction work. Previously, elevator-industry employers performing construction work needed only to be concerned with a general training requirement set forth at § 1926.21(b)(6). Since August 2015, however, a detailed construction PRCS standard with explicit training requirements has been effective. Although not set forth in the construction-industry matrix, OSHA specifically listed elevator and escalator pits as examples of potential confined spaces in construction work. Accordingly, it is imperative that elevator-industry employers performing construction work be aware of this standard, found at § 1926.1201 through 1213.

The construction industry PRCS standard is very similar to the general industry standard. For example, without addressing the specific criteria a pit must meet to satisfy the definition of a PRCS, it is highly possible OSHA would view a typical 5-ft.-deep elevator pit, needing a ladder to access, as a confined space. Should that pit then have the potential to contain a hazardous atmosphere (welding fumes? explosive vapors from glue?) or “any other recognized serious safety or health hazard” (moving equipment, such as counterweights or a temporary work platform?), an employer with employees working in the pit could be faced with a situation where OSHA believes training required by the new construction PRCS standard should have occurred. § 1926.1207(a) sets forth initial training and retraining whenever duties change or employee knowledge seems deficient. I expect OSHA will aggressively seek to apply the general industry and construction PRCS standards to the elevator industry. Fortunately, because of the close overlap between the general industry and construction PRCS standards, providing training to comply with the general industry requirements will likely satisfy construction requirements.

Another new construction-industry standard that elevator-industry employers need to consider (but which is not in the NEII construction training matrix) is the new crane and derrick standard for construction at § 1926.1400 through 1442. These requirements replace the old standard set forth at § 1926.550. This is important because companies performing elevator or escalator construction frequently have their own employees lift materials and equipment with cranes. Any employees engaged in this work, such as operators, signal persons or riggers, are subject to the detailed training requirements at § 1926.1430. This training must occur before employees perform such work, and retraining must be provided whenever there is reason to believe an employee’s knowledge is deficient.

All in all, the NEII summary training matrices for general industry and construction are an excellent guide for employers seeking to ensure that they are covering all of the topics at the correct frequency to comply with OSHA standards. Providing such training also helps position the company to defend against violations caused by employee failures to follow work rules. It is important to remember that, although the matrices are a strong start, they are not a substitute for a thorough analysis of the work environment, OSHA standards and consultation with a safety professional.

Get more of Elevator World. Sign up for our free e-newsletter.