The Best VT Solution

Apr 1, 2018

In this Readers Platform, your author describes the benefits of Peelle’s vertical-slide doors in Freight Applications

It’s important for a building owner or architect to properly communicate the purpose of a proposed facility when consulting with an elevator professional. Elevator professionals will conduct their own discovery, i.e., who will visit, how often, for what purpose and the amount of elevator traffic that will result. They will also consider which materials are being stored, produced or moved.

When materials are being moved, it’s appropriate to assess their size, weight and quantity to determine the best vertical-transportation (VT) solution. While most passenger elevators can serve a dual purpose as a service or freight elevator for the occasional furniture delivery, they are not appropriate for high-volume goods production or storage, which could damage hoistway door panels.

There are many options to move freight in a building. Freight elevators, because they are heavy duty and rated for non-public use, are different from both material lifts and service elevators. They are application specific and designed based on the needs of the building owner/end user that were determined during discovery. The types of entities occupying a space are almost limitless. Grocery stores, factories, distribution centers/warehouses, garages, museums, convention centers and power plants are a few examples. Freight elevators are suitable for any facility throughout which material is transported by cart, hand truck, pallet, lift truck or vehicle.

Although there are different options to move freight, the most appropriate elevator type to be specified should be based on the material being loaded, rated class of the elevator and where incidental hoistway door impact is likely. To ensure maximum service for the building owner/end user, both the elevator and hoistway doors need to be considered. Since, according to some estimates, 80% of shutdowns are attributed to the hoistway door system, the choice should be easy. There are only two options: horizontal-slide doors, most commonly seen on passenger/service elevators, or vertical-slide doors, traditionally known as freight elevator doors, which are associated with heavy-duty elevators used to move freight.

Selecting the right type of elevator is critically important for the operation of your facility. The multifloor parking garage can’t operate without automobile lifts, the retail store can’t sell goods if the goods don’t make it onto the shelves, the manufacturing facility can’t produce products without raw materials, and the shipper can’t load goods onto delivery trucks if goods can’t reach the loading dock.

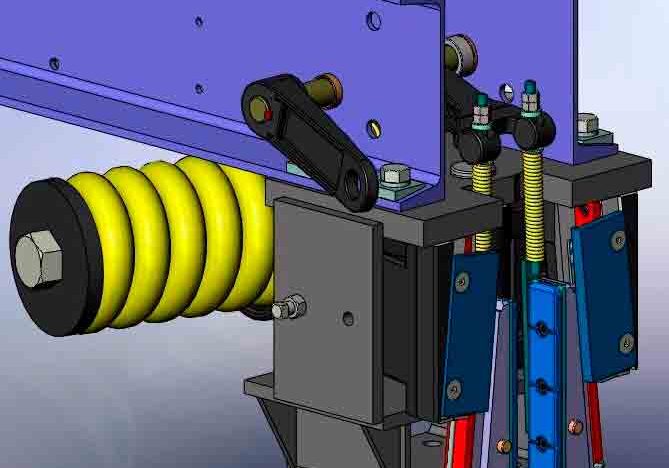

Vertical-, versus horizontal-slide doors, offer unique features. They are designed to provide long years of service to improve the lifetime value of the elevator. They offer the owner, facility manager and end user an option to help reduce shutdowns. Fewer shutdowns reduce elevator expenses and improve productivity, in turn maximizing sales. Some of their features are:

- Robust construction: Horizontal-slide doors are designed primarily for light-duty applications. This can result in damage due to incidental impact from loading misuse and abuse. Vertical-slide Peelle doors are designed specifically to the capacity and loading method of the elevator, are heavy duty and are reinforced to accommodate hand truck, pallet and forklift loading.

- Truckable sills: Horizontal-slide door sills are subject to damage, premature wear and debris infiltration, which affect door performance. Vertical-slide Peelle door trucking sills are specifically designed to the capacity and loading method of the elevator, and are flat to allow smooth loading. Door guides run vertically in the hoistway, so they do not become damaged during loading, and debris cannot gather in the door guides.

- Independent locks: Horizontal-slide doors that sustain a high impact may also suffer interlock misalignment, leading to a shutdown. Vertical-slide Peelle door interlocks are independent of the panels and located away from the openings, thus protected on the door guides.

- Space savings: Horizontal doors require a large amount of “return space” for the panels. Vertical-slide Peelle doors typically require 13 in. (330 mm) of return space. This means more usable building space.

- Sequence operation: Horizontal doors are subject to incidental impact during loading (when the entrance is not fully opened), causing a shutdown. Vertical-slide Peelle doors permit loading only when the hoistway and car-door entrance is fully open.

- Independent operation: Horizontal-slide doors have a mechanical coupling between the car door and hoistway door that can separate during heavy-duty loading, causing an elevator shutdown. Vertical-slide Peelle doors have independent operation with no mechanical coupling between the car door and hoistway door, allowing for heavy-duty loading.

A building owner/facility manager/end user can help ensure they are provided with an appropriate VT solution by engaging an elevator consultant. If a freight elevator with vertical doors is deemed the right solution, don’t accept an unsuitable substitution. The consultant and elevator manufacturer, along with their subcontractors, are responsible for specifying the right solution. The building owner has a responsibility to question product substitutions that modify the specifications driven by the discovery process.

Get more of Elevator World. Sign up for our free e-newsletter.