This History article examines the escalator as it came into its own.

The history of technical literature includes textbooks that have served multiple generations through multiple editions. One such iconic work is Mechanical and Electrical Equipment for Buildings, first published in 1935 and now in its 11th edition. Each new publication reflects editorial changes, the introduction of new authors and the steady introduction of new material. The book’s purpose was (and is) to provide a broad overview of mechanical and electrical equipment, and its intended audience was (and remains) engineering and architecture students. Thus, it offers an ideal lens through which to examine general information about and attitudes toward vertical transportation (VT) at moments in time.

The first edition covered elevators but not escalators. The second edition (1945) included a brief account of escalators in the chapter “Vertical Transportation.” The third edition, published in 1955, featured an entire chapter devoted to escalators.[1] The 13-page illustrated chapter provided a broad overview, which permits an assessment of escalator technology and use in the mid-20th century.

The chapter’s sources included “technical bulletins on elevators and escalators” provided by Otis and the Elevator Division of Westinghouse Electric Corp., and the ASME A17 code.[1] The specific industry contacts, mentioned in the book’s preface, included Edgar H. Nelson (Westinghouse) and A.W. Perryman and A.E. Feather (Otis). The version of the code reviewed by the authors was the revised 1937 edition (reprinted in 1945), which included new material created in 1942. This had been produced as part of a planned overall revision of the code that was delayed due to the impact of World War II. (The fifth edition of the A17 code was published in 1955.) The chapter’s content appears to indicate that the authors primarily relied on materials furnished by Westinghouse, a fact reflected in the chapter’s title, “Moving Stairways.” The authors introduced their topic by noting, “The moving stairway is frequently referred to as an escalator or as an electric stairway. Throughout this section, all three names will be used.”[1]

The fact that 20 years passed between the publication of the first and third editions of Mechanical and Electrical Equipment for Buildings and that it took that long for escalators to warrant a dedicated chapter serves as a reminder that the introduction of the escalator into the VT world was a lengthy process.

The authors’ examination addressed four primary topics: application or deployment in buildings, technology and safety, basic design parameters, and cost. The authors began by stating:

“Escalators are selected where larger numbers of people are scattered throughout a given area and on a number of floors; these people are interested in moving about almost continuously to various locations for short periods of time. Thus, traffic is constantly on the move, both up and down, and usually has a rather uniform base load with only occasional peaks.”[1]

Buildings or settings appropriate for escalators included large department stores and transit systems (subways, bus terminals and train stations). The advantages of escalator use in these settings was characterized as follows:

“The escalator not only delivers passengers comfortably, rapidly and safely, but also continuously receives and discharges its live load at a constant speed with practically no waiting periods at any landing. The many seconds of time which are lost by elevators are not present on traveling stairways. For example, time is not lost by acceleration, retardation, leveling, door operation [or] operator’s reactions; nor by pressing hall buttons, by passenger interferences in getting in or out of the cars, etc. One seldom sees a waiting passenger or congestion of passengers at the lighted comb plate of an escalator.”[1]

One of the interesting aspects of this comparison is the reference to operators. This serves as a reminder that, in the mid-1950s, most elevators still required operators — the new operator-less elevators were found only in recently completed “modern” buildings. The escalator was also presented as a system that could be easily added to an existing building:

“The corridors, aisles and other passageways in existing buildings usually provide space for floor openings adequate for the installation of escalators. In contrast, it would, in most cases, be almost impossible to install an adequate bank of elevators in an existing building to meet the growing needs for vertical transportation.”[1]

Within the realm of installation, the authors also addressed the impact of escalators on building life-safety system design. Although the 1955 edition of the A17 code was not referenced by the authors, they may have been aware of the changes it contained. Among the new rules was one that addressed the protection of floor openings: “Rule 800.1 Protection Required. Floor openings for escalators shall be protected against the passage of flame, smoke or gases in the event of fire.”[2] This may explain the authors’ detailed discussion of four different methods of

“affording protection in case of fire near escalators. . . the rolling shutter, the smoke guard, the spray-nozzle curtain and the sprinkler vent.” The descriptions of three of these systems were accompanied by illustrations depicting their basic components and installation characteristics (Figures 1-3). Additional installation images included drawings of the two basic configuration paradigms: crisscross and parallel (Figures 4 and 5).

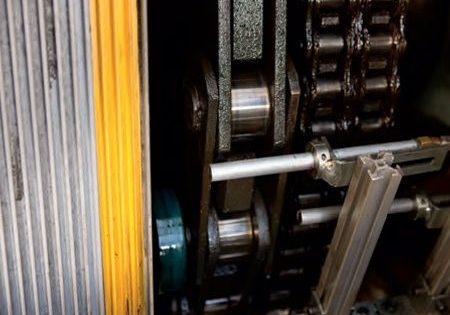

The technical discussion of escalators focused on the truss system and safeties. The truss was described as comprising three sections: upper and lower curving trusses, which carried “the complete weight of the stairway mechanism and its live load” and the straight truss that connected the top and bottom sections.[1] The authors noted that the “middle section may be any desired length to provide rises for floor heights of from, say, l0 to 23 ft. When the rise is over 20 ft, an intermediate support is located between the two end supports of the stairway.”[1] Basic safety features discussed and illustrated included the deck boards, inside panels, skirt guards, handrail guards, handrails and combplates (Figure 6). In addition to these components, the authors described various safety devices:

- “[The] automatic controls of a service brake bring the stairway to a smooth stop if electric power or mechanical parts should fail. Passengers would then walk the steps as they would any stationary stairway.

- “In case of overspeed or underspeed, an automatic governor shuts down the escalator and prevents reversal of direction (up or down) and operates the service brake.

- “An emergency stop switch is located near the combplate or in some unobtrusive location. Building employees and adult passengers may operate the switch to stop the escalator. A key-operated up-starting switch and another down-operating key-operated switch is available near the emergency

stop switch.”[1]

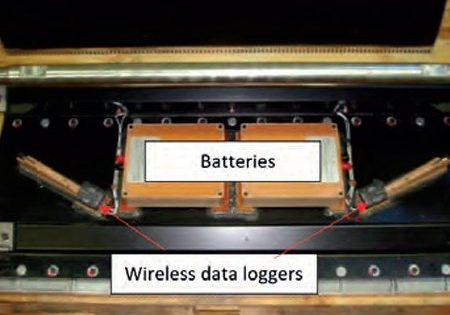

A foldout page with working drawings of a Westinghouse Type 32L Electric Stairway was also included, which provided detailed construction and installation information (Figures 7 and 8). The basic operational and design parameters were defined as:

- Speed: 90 or 120 ft/m

- Angle: 30°

- Stair depth: 16 in.

- Tread height: 8 in.

- Typical widths: 32 and 48 in. (considered standard production models)

- Maximum height: 25 ft

- Contract load: 4.6WA, where W is the nominal width of the escalator in inches, and A the horizontal projection of the length of the exposed treads in feet. For a 30° incline, A is equal to √3H, where H is the vertical rise of the escalator in feet (floor-to-floor height).

Escalator traffic analysis was characterized as “extremely simple, since the rates of travel are specifically given for the standard sizes, rises and speed.”[1] The imagined capacity was described in terms of passenger type:

“The passengers per step may vary, depending upon whether adults or children are considered. In general, one adult and two children, or two adults may easily stand on the 32-in. tread; three adults may easily stand on a 48-in. tread.”[1]

The suggestion that three passengers could ride on a single step ignores the fundamental safety guideline that passengers should hold onto the handrail while traveling. The authors also did not specify whether they imagined that every step would be occupied when calculating capacity (Figure 9).

The chapter’s conclusion addressed the issue of cost. The authors noted that the:

“. . .cost of an escalator includes the cost of the associated mechanical and electrical equipment, plus the shipping [and] installation charges. The manufacturer provides expert engineering and a union field erector who supervises the installation, which is done by unionized elevator and escalator mechanics.”[1]

They claimed that a “general average rule-of-thumb for quick estimating of costs for a 32-in. electric stairway, installed, is US$26,000 for the first 10 ft of rise and US$750 for each additional foot; the corresponding figure for a 48-in. stairway is US$32,000 and US$1000 for each additional foot.”[1] These estimated costs were for a Westinghouse electric stairway. They were also presented in a chart that allowed users to easily estimate the cost of an escalator for a given setting (Figure 10). The chapter’s final sentence reminded readers of the importance of working with VT specialists:

“It is especially important that the assistance of experts in vertical transportation be employed in the engineering analysis, specifications, installation and costs involved on all projects.”[1]

The fact that 20 years passed between the publication of the first and third editions of Mechanical and Electrical Equipment for Buildings and that it took that long for escalators to warrant a dedicated chapter serves as a reminder that the introduction of the escalator into the VT world was a lengthy process. While the invention of a new form of VT is often accompanied by a vision of its application, it is the actual use of a given system that reveals its strengths and weaknesses and suggests necessary improvements. Additionally, while, by the mid-20th century, the escalator was almost as well-known as the elevator, in was still sufficiently “new” and “unique” that American newspapers in 1955 continued to report (often with great enthusiasm) on the first escalator installed in their city.

References

[1] Charles M. Gay, Charles De Van Fawcett and William J. McGuiness. Mechanical and Electrical Equipment for Buildings, Third Edition, New York: John Wiley & Sons (1955). [2] American Society of Mechanical Engineers. American Standard Safety Code for Elevators, Dumbwaiters and Escalators, Fifth Edition, New York (1955).

Get more of Elevator World. Sign up for our free e-newsletter.