The Inspection of the Taipei 101 Elevators: 10 Years Later

Dec 1, 2014

The elevators that were the fastest in the world until this year are thoroughly examined.

by Toshiaki Nakagawa and Shunta Sasaki

The 1,010-mpm elevators installed in Taipei 101 in Taipei have operated normally for nearly 10 years since their opening in 2005 (ELEVATOR WORLD, September 2005). These elevators are provided with special devices, such as in-car atmospheric pressure control and an active damping device, for supporting ultra-fast and -long travel. Toshiba Elevator and Building Systems Corp. comprehensively inspected these devices concerning deteriorations by long-time operation and the changes in riding comfort (such as car vibration). It confirmed that the units have provided good service and are capable of offering sufficiently safe and comfortable services.

Taipei 101 was completed at the end of 2004 and is 508 m tall, the world record at the time. Toshiba’s two ultra-high-speed elevators were also a world record (for speed), which stood until November 2014. The elevators were developed with the view of achieving not only this record, but also satisfactory riding comfort. Toshiba also made efforts to secure such reliabilities as safety and long life of the devices. To meet these requirements, new devices, such as a high-power traction machine and safety devices, were designed in accordance with large capacity at ultra-high speed. In addition to providing quality control of the elevators through periodic maintenance and inspection, Toshiba comprehensively inspected the elevators in June 2010 and June 2014. This inspection intended to check whether the devices maintained the same condition of performance and reliability as when they began operation.

Elevator Outline

Table 1 lists the main specifications of the 1,010-mpm elevator. It takes approximately 39 s. to run from the ground floor (B1 level) to the observatory of (89th floor) 382 m above the ground. The units are provided with a wide variety of specially developed devices to achieve stable travel at full speed and ensure safety and comfort.

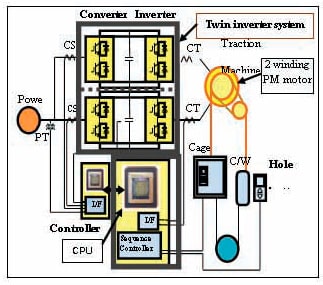

Drive System

The traction machine is a fast and large-capacity machine employing a two-winding permanent-magnet synchronous motor (PMSM). A twin-drive system is employed for independently controlling dual converters and inverters. The traction machine and control system have been subjected to periodic maintenance for examination of their operations.

Atmospheric Pressure Control System

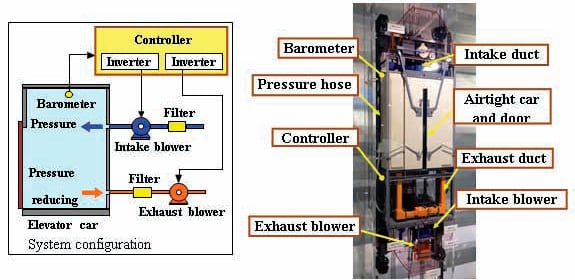

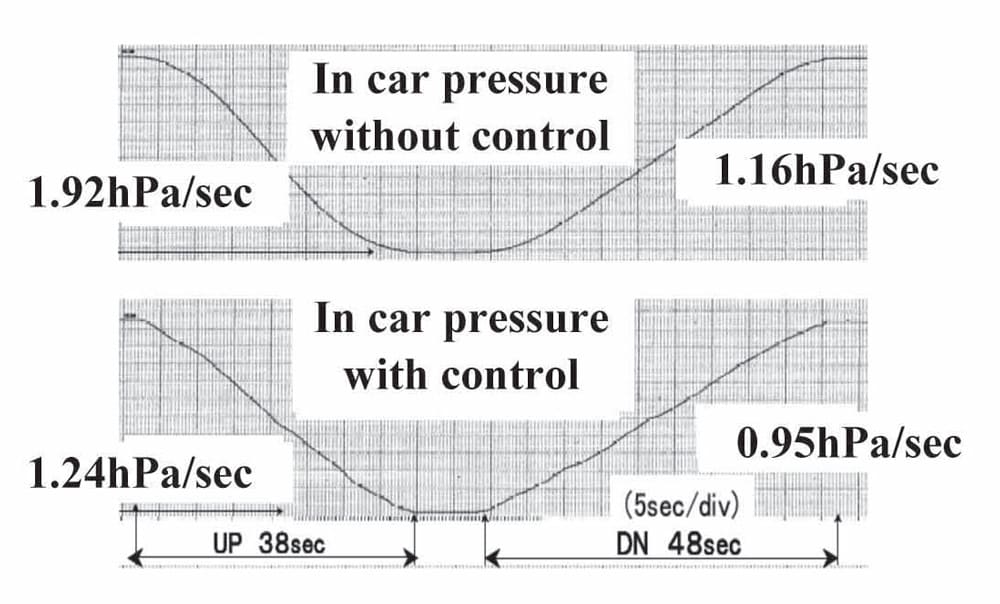

An atmospheric pressure difference of about 48 hPa arises between the ground and the highest floor at which the elevator stops in Taipei 101. This would cause passengers to experience uncomfortable stuffiness in their ears while moving up or down at high speed. To overcome this challenge, Toshiba developed the first atmospheric pressure control system for application in an elevator car. A decompression testing chamber was set on the ground, and tests of changing the pattern of atmospheric pressure change were made of both men and women, young and old. The tests proved that the stable rate of pressure change was acceptable. Therefore, the rate of atmospheric pressure change in the elevator car was controlled to be constant by supplying air into and discharging air from the elevator car using an exhaust blower and an intake blower.

It is necessary to ensure that the elevator car is sufficiently airtight to control the atmospheric pressure within it. For this purpose, special rubber is provided between panels of the elevator car. Furthermore, the elevator is structured so that when the door is closed, the door panel is made to sink to reduce the door gap. The rates of atmospheric pressure change in the elevator car while the elevator was moving up and down were 1.26 hPa/s and 0.95 hPa/s, respectively. These measurements are similar to the values of 1.24 hPa/s and 0.96 hPa/s measured when the elevator began operation.

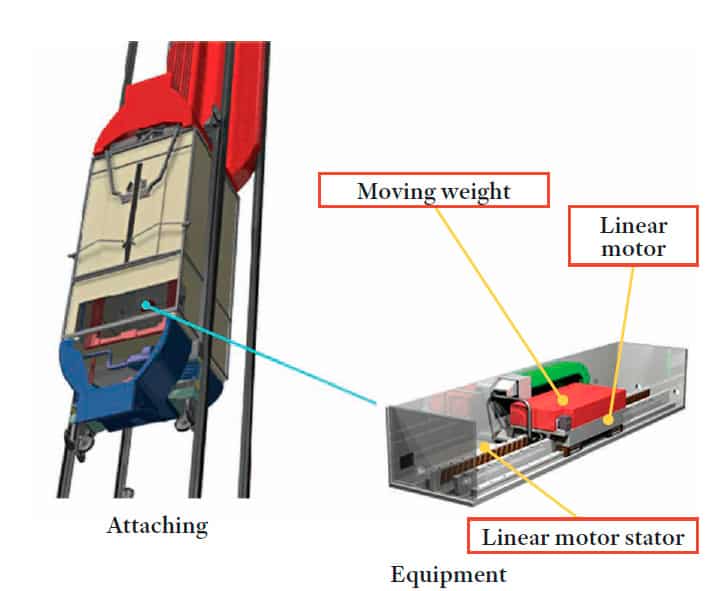

Active Mass Damper

Toshiba developed and adopted an active mass damper (AMD) to prevent the elevator car from swaying due to bends, curves or bumps in the guide rails. The AMD detects sway of the elevator car with a sensor and operates a movable weight by a linear motor to cancel out the sway and suppress vibration. The AMD is installed at the lower portion of the elevator car. In this comprehensive inspection, we checked the AMD devices and investigated whether the vibration restraint performance was maintained.

The vibration data measured by the acceleration sensor installed in the AMD was compared against the data by a new 2G acceleration sensor to check whether the acceleration sensor in the AMD performed normally. We also checked car vibration performance when they passed by each other. No decrease in the performance of the acceleration sensor was found. When the cars passed by each other, vibration was approximately 0.15 mps2, which was found to be almost equivalent to the data measured when the elevator began to operate.

Ride Comfort Performance

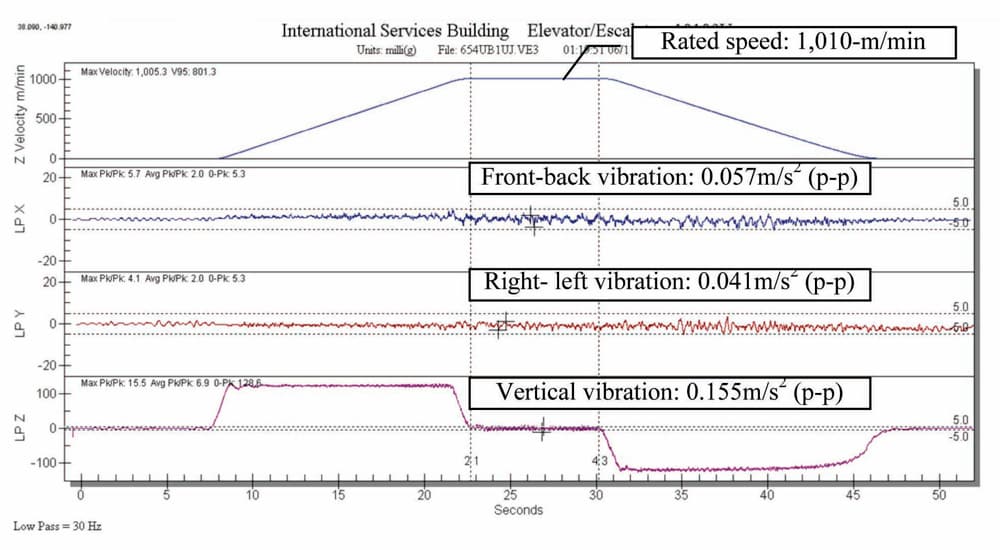

Toshiba checked the vibration and noise of the elevator car, not only in the case of the rated speed of 1,010 mpm, but also at 1,101 mpm. The upper and lower, right and left, and front and backward car vibrations were very small. Comfortable riding was realized, despite speeds exceeding 1,000 mpm. We assumed this would be the same at speeds of 1,010 mpm (Figure 9). We confirmed the performance is almost the same immediately following installation. Though vibration increases a little when at the speed of 1,101 mpm, it is adjustable by the selection of parameters, which realized comfortable riding (Figure 10).

Summary and Conclusion

A main reason these elevators maintained very good performance without any major trouble over 10 years of operation is the regular checking of their condition and maintenance of them. A business partner, Golden Friends Corp. Ltd. of Taiwan, makes every effort to service the units for maintenance. Toshiba taught Golden Friends the maintenance plan and manages it. We will continue this process, including regular and comprehensive inspection for performance and quality. We believe this elevator system’s technology remains advanced, even after 10 years.

Figure 1: Taipei 101

Figure 2: Traction machine

Figure 4: Atmospheric pressure control system

Figure 5: Pressure change in car by atmospheric pressure control device upon installation completion

Figure 6: Pressure change in car by atmospheric pressure control device at this inspection

Figure 7: AMD

Figure 8: AMD sensor performance

The-Inspection-of-the-Taipei-101-Elevators-10-Years-Later-Figure-8

Figure 10: Car vibration of elevator OB38 (1,101 mpm, upward)

Table 1: Main elevator specifications

References

[1] Yoshiaki Fujita, Tadashi Shudo, Masaaki Hirai, Kousei Kamimura, Sueyoshi Mizuno and Toshiaki Nakagawa. “1,010m/min Elevator Installed in the Taipei101, Elevator,Escalator and Amusement Riders Conference” (2005), The Japan Society of Mechanical Engineers, Lecture, collected papers, p.31-34.

[2] Toshiaki Nakagawa, Takashi Nishikawa and Hiroyuki Kimura.

“High-Reliability Technologies for World’s Fastest Elevators,” Toshiba Review, Vol.60 No.5 (2005), p.26-29.

[3] Tadashi Shudo, Kosei Kamimura and Shingo Maeda. “1,010m/min Elevator Installed in the Taipei101 Building,” Elevator Technology 15: Proceedings of Elevcon 2005, p.185-194.

[4] Hiroaki Mizuguchi, Toshiaki Nakagawa and Yoshiaki Fujita, “High-Speed Elevators in Taipei 101,” ELEVATOR WORLD, September 2005, p.71-76.

Get more of Elevator World. Sign up for our free e-newsletter.