The National Ski Jumping Center of the 2022 Beijing Winter Olympics

Jan 1, 2022

Inclined Lifts

Zhangjiakou, China

submitted by Jiang Liming, Suzhou Rhine Lift Manufacture Co., Ltd.

Project Overview

The 2022 Beijing Winter Olympics are planned to be jointly held in Beijing and Zhangjiakou, Hebei Province, from February 4 to February 20, 2022. This is the first time that the Winter Olympics will be held in China.

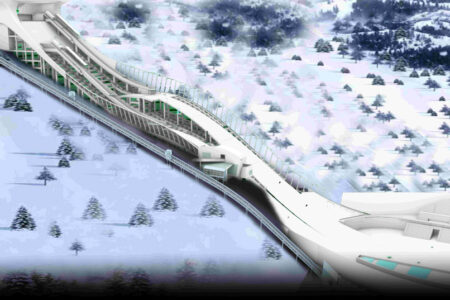

The National Ski Jumping Center is one of the most complex and technically difficult competition venues in the 2022 Winter Olympics in Zhangjiakou. The design concept comes from the traditional Chinese ornaments Ruyi, which means auspiciousness, so it is also known as “Snow Ruyi.” Because of its unique architectural style, “Snow Ruyi” has become the most eye-catching venue in the 2022 Winter Olympics.

The National Ski Jumping Center is the first ski jumping venue in China. It consists of the Peak Club (departure area) at the top of the mountain, the grandstand area at the bottom of the mountain and two racetracks. One of the two tracks has a drop of 136.2 m (large platform track) and the other has a drop of 114.7 m (standard platform track).

The Transportation System

To contribute to the Olympic effort, Suzhou Rhine Lift Manufacture Co., Ltd. designed, manufactured and installed two inclined elevators for the National Ski Jumping Center. The elevators have passed the acceptance inspection and were put in use in July 2021.

During the Winter Olympic Games, the Rhine inclined elevators will serve as the skiers’ on-site transportation, helping them move up and down between the bottom and the top of the ski jumping platform.

Installation Challenges

The inclined elevators for this project are installed on the mountain. Firstly, due to the steep mountain, the transportation of materials became a big problem. Secondly, the climate in Chongli of Zhangjiakou is very special. Winter begins in October. Early snowfall, thick snow and long snow periods brought great challenges to the inclined elevator construction. Therefore, modular installation was carried out for this project. The car was formed in the factory and hoisted and assembled on-site. This greatly improved installation quality and efficiency. At the same time, it reduced scratches on car surfaces in the assembly process.

Technology Innovation and Highlights

- Challenges caused by low ambient temperature: The temperature in Chongli, Zhangjiakou, is very low in winter, with the lowest temperature ever reaching -32°C. This requires low temperature resistance for outdoor materials and components.

- Low temperature resistant components are used in the speed reducer and levelling inductor in the shaft.

- The metal structure is made of materials no less than GRADE C, which are suitable for low temperature operation.

- The guide shoes are made of specially customized carbamate with low temperature resistance and can be adapted to a -40°C environment.

- The cables in the shaft can be adapted to low temperatures.

- The oil inside the buffer is low temperature resistant hydraulic oil.

- Other necessary parts are adapted to low temperature.

- The inclined elevators of this project have variable inclination. They are located next to the National Ski Jumping Center. The running inclination changes with the mountain shape, thus, there is an arc guide rail section in the middle. This is the first inclined elevator project with variable inclination in China, and also the fastest outdoor inclined elevator project with variable inclination in China.

- For this project, conventional elevator traction machines did not meet the requirements, so the traction machines of this project are specially customized. Speed reducers from Siemens Foolad and brakes imported from Japan Sanyo were used in the traction machine design.

- Communications and power supply between control system and car were carried out by wireless communication signal control and safety slip contact line solution. Because the running inclination changes, the traditional wired way could not be applied in this project. Wireless communication is used to transmit the signal of floor selection. For safety locks and safety loops, safety slip contact lines are used to confirm physical safety.

- This is the first time that electric cylinders have been applied to inclined elevators. The use of electric cylinders can solve the problem of low temperature resistance. Compared with hydraulic systems, it can reduce after-sales problems.

- Car doors and landing doors are controlled without a mechanical door vane. It solves the problem that the door vane structure cannot be used due to the change of running inclination. The landing doors also adopt a drive door system with control.

- The guide rail system is integrated with the steel structure. In this way, the structure is simple and the construction is convenient.

- Variable running speed design. Taking into account the running effect of the inclined elevator on the arc guide rail, variable running speed design is adopted. The inclined elevator decelerates before entering the arc guide rail section, and then speeds up after passing the arc guide rail section. Such design makes the inclined elevator running process more stable.

Credits

Developer: Zhangjiakou Olympic Sports Construction and Development Co., Ltd.

Architect/ Designer: Zhang Li (Dean of School of Architecture, Tsinghua University)

Project contractor: China Railway Construction Engineering Group Transportation System

Contractor: Suzhou Rhine Lift Manufacture Co., Ltd

Equipment manufacturer: Suzhou Rhine Lift Manufacture Co., Ltd.

Get more of Elevator World. Sign up for our free e-newsletter.