Sometimes-overlooked procedures are important for hydraulic elevators.

Hydraulic oil is the lifeblood of the hydraulic system; it is estimated that 80% of failures in an oil system are related to oil quality and cleanliness.[1] However, little attention has been given to the oil in the hydraulic elevator over the past 40 years.

The elevator code has no specific requirements for the hydraulic oil, and the elevator service contract rarely addresses oil quality or ownership; as a result, the oil is not addressed. This results in failures of covered components, like seals, valves, submersible motors and piston rods.

Mineral-based AW-32 is the most commonly used oil in the elevator industry; however, vegetable and synthetic oils are beginning to see additional use. If a baseline sample of the oil is available, it is possible to determine the rate of oxidation in the oil or the oil’s ability to perform as required by the hydraulic system.

TAN

The total acid number (TAN) is a measure of base oil degrading and is a reliable indication of oil aging. AW-32 has a TAN of 0.3 due to the addition of additives; as the additives are depleted, the TAN will drop to 0 before increasing rapidly. A TAN delta increase of 1 is considered to be out of tolerance for most hydraulic oils; once it gets past +2, the oil is no longer fit for further use, and continued use can lead to failures. The most common problem associated with high TAN is early seal failure.

Viscosity

Viscosity is a measure of the oil’s resistance to flow; most elevator components, including seals, valves and pumps, are designed to operate with an oil viscosity of 32-46 centistokes. When the viscosity is too low (a delta of -6 centistokes), adhesion between the seal and rod will result in low-speed vibrations and burnishing of the piston rod. A burnished piston will have increased surface contact between the seal and rod, resulting in premature seal failure.

An increase in viscosity, a delta of +2, can be a result of oil contamination or oil oxidation. When the oil viscosity is too high, increased heat loads are placed on the power units, and leveling issues will develop due to the reduction in viscosity index.

Viscosity index (VI) is a measure of the stability of the oil’s viscosity between 40°C and 100°C. AW-32 has a viscosity of 32 centistokes at 40°C and around 8 centistokes at 100°C. As the low-temperature viscosity increases the swing between the high and low temperatures, viscosity becomes wider, and the valve becomes difficult to set. This is observed by cars that overshoot the floor early in the day and struggle to reach the floor later in the day.

Contamination

Contamination can alter the VI of the oil, resulting in excessive component wear and unintended movement. There is no standard in the elevator industry for VI. New mineral-based oils have a VI between 90 and 120; vegetable and synthetic oils can have a VI up to 200. Contaminated oil can have a VI as low as 50 or 60; cleaning the oil can restore the VI closer to its original levels. Note that cleaning the oil does not alter the VI; it removes contaminants that affect the oil’s performance, increasing the VI reading. It is recommended that the VI be monitored and kept above 90.

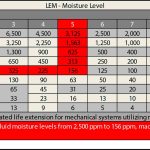

Water is the most common contaminant in the hydraulic elevator system due to the hydroscopic nature of hydraulic oil and the open reservoir utilized in hydraulic elevators. Even as little water as 250 parts per million (ppm) can alter the transition and leveling times of the elevator, resulting in excessive heating and rapid oil oxidation. Water will react with the common oil additive ZDDP when reservoir temperatures exceed 130°F, resulting in seal and pump wear, as well as increased oxidation of the oil and acid formation.

Water entrains air in the oil, resulting in pump cavitation and micro-dieseling. Micro-dieseling is the fracturing of the hydrocarbon molecules as air bubbles travel from an area of low pressure, the reservoir, to an area of high pressure, the pump. Due to the frequent and prolonged bypass times present in hydraulic elevators, micro-dieseling is a common source of oil degrading. This change is permanent and cannot be reversed.

Water reverses the chemical process used to make ester-based and vegetable oils, and leads to oil breakdown, polymerization and rancid smells. Hydrolysis changes the oil chemically and cannot be reversed. Keeping a vegetable oil dry is of paramount concern.

Small particles (5-15 microns in size) are the most detrimental to moving and sliding components, because they can enter the small clearances in the system and cause pump and valve wear. Typically, the hydraulic elevator does not have any form of oil filtration.

Inline filtration is not practical due to elevator flow rates. To filter objects smaller than 5 microns, the filter would have to be impractically large to allow a sufficient flow rate for proper elevator operation. Offline filtration is a practical way to filter properly without affecting elevator oil flow or operation.

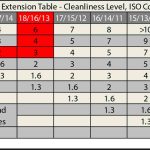

ISO 4406:99 Cleanliness Level Standards measures the number of particles greater than 4 microns per milliliter of oil. This standard is common in other industries, with specific limits for different types of equipment — for example, computer-numerically-controlled milling machines and plastic injection machines. However, there is not a standard for elevators. Maxton Manufacturing Co. recommends filtration of 5 microns or smaller. The company reported, “Approximately 20% of the valves sent back for warranty are contaminated. The other 80% are misadjusted or no problem was found, and 90% of all valves sent back for repair are contaminated.”

Improvements in International Organization for Standardization (ISO) cleanliness codes can be correlated to show increases in equipment dependability and life extension (Table 2). A decrease of the ISO code from 22 to 18 represents a life extension factor of three times. It is your author’s recommendation that the maximum ISO code for a hydraulic elevator be 20, which is 5,000-10,000 particles per milliliter of oil; the ISO target should be a code of 18, which is 1,300–2,500 particles per milliliter of oil.

An elevator maintenance control program (MCP) that includes TAN, viscosity, VI, water content and the ISO cleanliness code will increase the service life of the equipment and provide achievable goals that can be quantified by existing tests currently utilized in other industries.

The system components of the hydraulic elevator system are very robust; by introducing standards and regularly monitoring the oil condition, we can reasonably expect to increase the service life of the hydraulic equipment by two to four times. An annual oil analysis, at minimum, should be conducted to identify potential problems to prevent unplanned shutdowns.

Because oil analysis and maintenance have a direct impact on the service life and reliability of the elevator equipment, they are more critical for sites with fewer vertical-transportation options. The cost of an elevator failure or outage at a location with one elevator is higher than when there are multiple elevators. For example, an assisted-living center with one elevator has a more critical need than a hospital that has a bank of four elevators to spread out the risk.

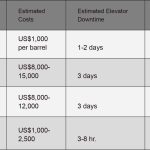

The cost of a single breakdown far outweighs the cost of regular testing and remediation. The annual cost of an offline filtration unit for an elevator is around US$600 per year and does not require the elevator be shut down to maintain the oil. (Annual cost is based on the purchase of a filtration unit with a 30-year life expectancy and one filter insert per year.)

In critical locations with a limited number of elevators, it is reasonable to increase the frequency of the oil analysis and filtration to prevent expensive breakdowns and outages.

Data Tracking

Data tracking is valuable to the building owner and the prospective service company. As part of an effective MCP, historical data of oil condition and its trends will alert the building owner of possible problems that may be developing, allowing remediation steps to occur prior to a failure. Annual maintenance with predictable outages will allow the building owner to manage downtime, instead of being forced to react to it.

Clean oil is also a negotiating tool for building owners, as it reduces the service company’s unknowns. Considering that 80% of the failures in an oil system are oil related, oil that has been maintained and documented is more desirable, because it is less likely to cause a failure of the oil system.

Conclusion

Standardized tests for TAN, viscosity, water, VI and oil cleanliness make oil analysis a reliable tool by which to increase the service life and dependability of hydraulic elevators through proactive maintenance. Offline filtration protects the oil, the lifeblood of the hydraulic system, and can extend the service life of the equipment and increase the reliability of the elevator system. Both oil analysis and offline filtration should be considered an essential part of elevator maintenance.

Acknowledgements

- Hal Gorman — Gorman Co., Inc.

- Dan DaCosta — EnBio Industries

- Eric Peterson — American Accessibility Technology

- Karl Keller and Billy Shrum — Maxton Manufacturing Co.

- Peter Smyth — C.C. Jensen A/S

- Sumary

- Table 1: Moisture level has a direct impact on the life of the oil and hydraulic-system components; there is a direct correlation between moisture content and machine life.

- Table 2: A decrease of the ISO code from 22 to 18 represents a life extension factor of three times.

- Table-3

Reference

[1] C.C. Jensen A/S. “The Importance of Oil Maintenance,” Clean Oil Guide.

Get more of Elevator World. Sign up for our free e-newsletter.