“The Vertical Transport of Goods”

May 1, 2021

Examination of a 1932 brochure by U.K. manufacturer Marryat & Scott reveals an early VT industry encounter with modern architecture.

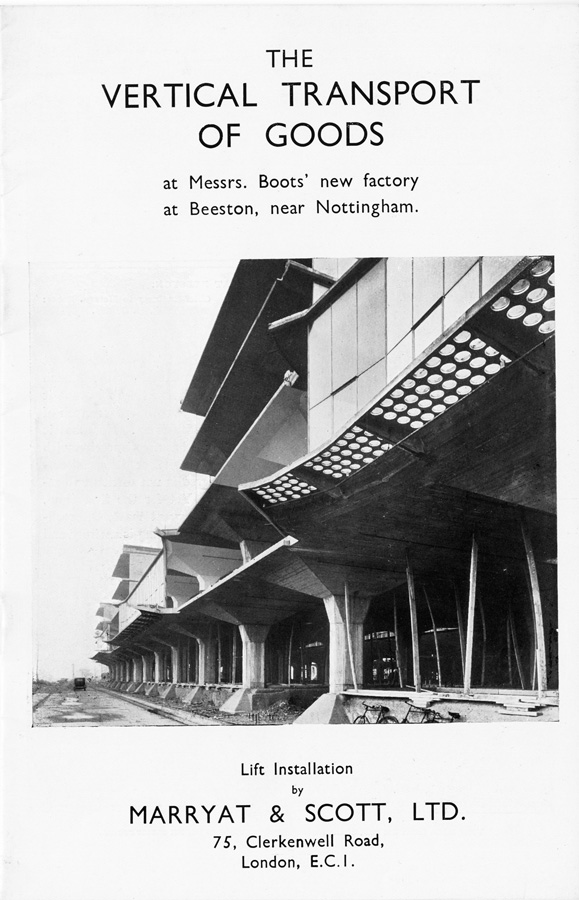

In 1932, the firm of Marryat & Scott, Ltd. published an illustrated promotional brochure that described its elevator installation in a recently completed British factory. While the publication of a brochure was a well-established commercial strategy, the decision to focus on a factory installation was unusual. The Marryat & Scott brochure also appears to have been written by someone outside of the company, perhaps a journalist. The basis for this assumption is an analysis of the writing style and tone, overall content and images. The first four pages of the 15-page brochure were devoted to a description of the building, and six of the 15 images depict the building’s architectural and engineering features. A photo of the building is also on the cover, a site typically reserved for an image of elevator machinery. The reason for this intriguing shift in advertising appears to have been an attempt to directly link Marryat & Scott to the emerging world of modern architecture.

The brochure’s opening paragraphs set the tone:

“There is always a moment in the development of any art in which originality of design and logical use of material entitle one to say that a new point of departure has been reached. . . . Messrs. Boots’ new factory at Beeston, near Nottingham, is such a work. . . . For the first time, in this country at least, the technique of the building is entirely and absolutely logical, owing to tradition only what is essential to the main conception.”[1]

The building perceived as a “new point of departure” was the Boots Pharmaceutical Factory, designed by English engineer/architect William Owens and built in 1930-1932. The assertion that the project represented a new, modern approach was supported by a discussion of the building’s concrete structural system, extensive use of glass and logical planning (Figures 1 and 2). Were it not for later events, this claim might be easily dismissed as hyperbole employed by the writer(s) to enhance their client’s reputation.

In 1940, English architect J.M. Richards, in An Introduction to Modern Architecture (which included an early assessment of British modern architecture), referred to the Boots factory as “one of the first large-scale modern buildings in this country [and] still one of the best.”[2] Approximately 40 years later, English architectural historian William J.R. Curtis called the factory one of the “most remarkable buildings of the modern movement in England.”[3] A survey of contemporary histories of modern architecture reveals that the building continues to be perceived as an important work of early modern architecture.

Marryat & Scott’s recognition of the building’s importance and apparent agreement with the author’s assessment is intriguing. (Regrettably, the author’s identity remains unknown; they were simply cited as “L.F.E.” in the brochure). It is possible this represents a new trend of elevator manufacturers seeking to adjust their product lines to meet changes in architectural style. The connection between elevator design and architectural design is, in fact, a topic that deserves further study.

In this instance, given the overtly modern design employed by Williams, Marryat & Scott’s response was to provide 10 large freight elevators at strategic points throughout the factory to facilitate the flow of goods and support the manufacturing process. The latter fact was highlighted by the author in a somewhat exuberant fashion:

“The success of a manufacturing plant, as that of an army in the field, which in many ways it resembles, depends on its internal communications. Evil communications, in fact, corrupt good managers. In this building, communication between [floors] depends largely upon lifts, whose shafts are focal points in the design.”[1]

The system featured large cabs, approximately 7-1/2 ft wide by 12 ft deep, and each elevator had a 4000-lb capacity. All the elevators also employed push-button control.

In their discussion of this (and other aspects of the system), the author often displayed a somewhat condescending attitude toward the factory’s employees. The use of push buttons was perceived as important, because the elevators would be in “constant use by the girl operatives.”

One critical aspect of the installation that was not fully automatic was the elevator doors, which consisted of manually operated, vertical biparting shutters (Figure 3). The doors were designed such that they could “be handled smoothly and easily by the youngest employee.”[1] The rationale for the use of this door type included an assessment of the factory’s production needs. The vertical door system provided an:

“. . .absolutely clear approach from any angle with no loss of floor space, and they prevent the movement of trucks or goods into the lift until they are fully and properly opened, thus saving the damage frequently caused both to trucks and to the lifts themselves when the more usually fitted gates are only partially drawn back. . . . The ease of handling thus insured seems of even greater importance when one realizes that many of the loaded trucks are handled by women and are frequently loaded with glassware.”[1]

The only exception to the use of vertical doors was found in the basement, where it was decided that it was too difficult to provide space for the lower shutter to pass below floor level.

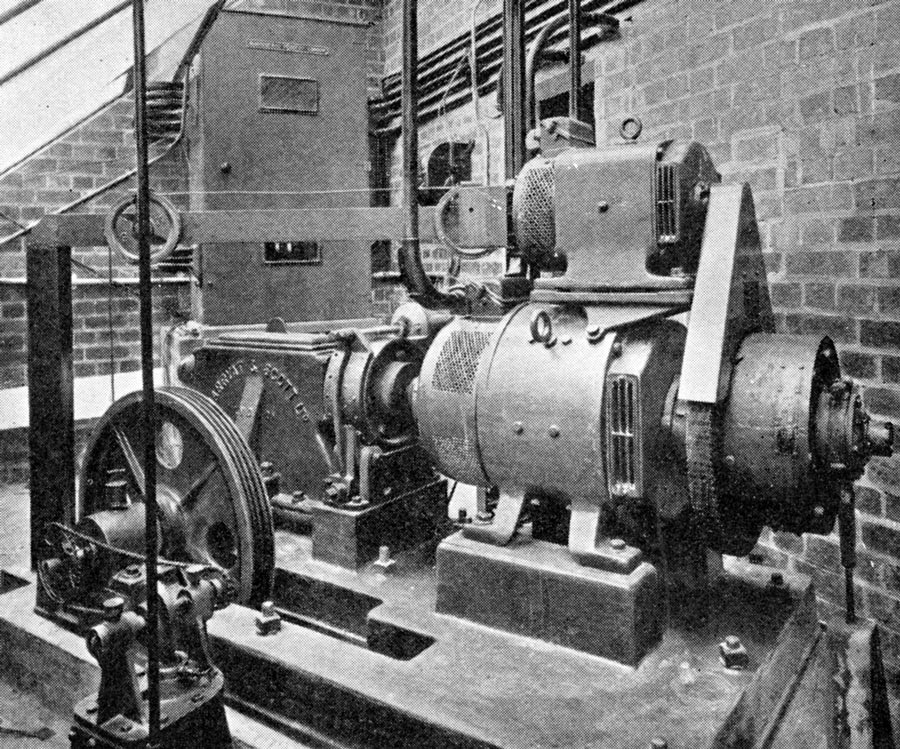

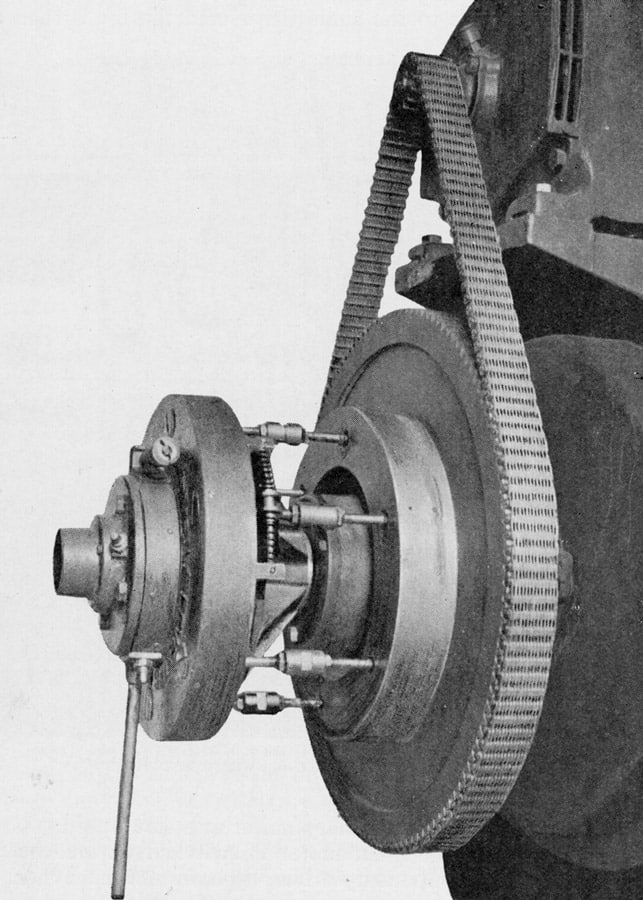

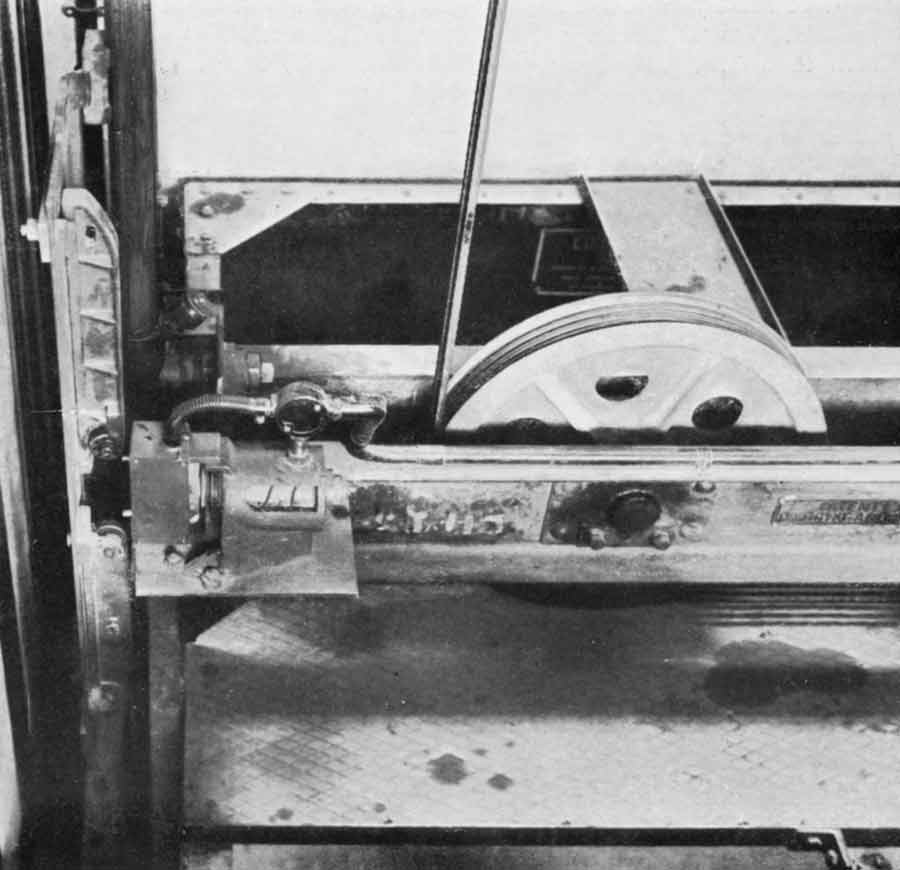

A critical aspect of successful elevator operation in this setting, with goods moved throughout the day on a variety of wheeled carts, was the automatic leveling system. Marryat & Scott had developed and patented the Leveltric system in the mid-1920s. This system employed a slow auxiliary motor mounted on top of the main motor. The two motors were connected by a chain drive equipped with a speed-operated clutch (Figures 4 and 5). When a car approached a landing, the clutch would engage the auxiliary motor and connect it to the drive shaft, while turning off the main motor. The auxiliary motor would then stop the car at the landing. This action was controlled by a leveling switch mounted on the car. The switch was equipped with two sensors that extended when the car approached a designated landing. Depending on the direction of movement, the upper or lower sensor would engage a panel mounted in the shaft. This action would close the circuit of the auxiliary motor, which would take over from the main motor and level the car. The auxiliary motor would disengage after both sensors entered a depression in the center of the panel (Figure 6).

The brochure’s author saw the Leveltric system as emblematic of Marryat & Scott’s approach to elevator design:

“In these lifts, there seems to be no conceivable part of the mechanism which is not, so to speak, censored by some automatic device ready to correct any sign of weakness or strain. There is electromagnetic braking, which takes charge in the event of any failure of current; there is an additional brake on the car in case of any accident to or defect of the winding machinery; there is a safety device to discern and correct any inequality of strain on the guide ropes; there are devices to prevent the shutter doors being opened when the car is not at their level; and there are, of course, the usual precautions against simultaneous calls from different floors; in fact, after a careful investigation of the safety features, one feels that it would require a considerable mechanical knowledge and a positively devilish ingenuity to contrive to hurt oneself in any way while handling these lifts.”[1]

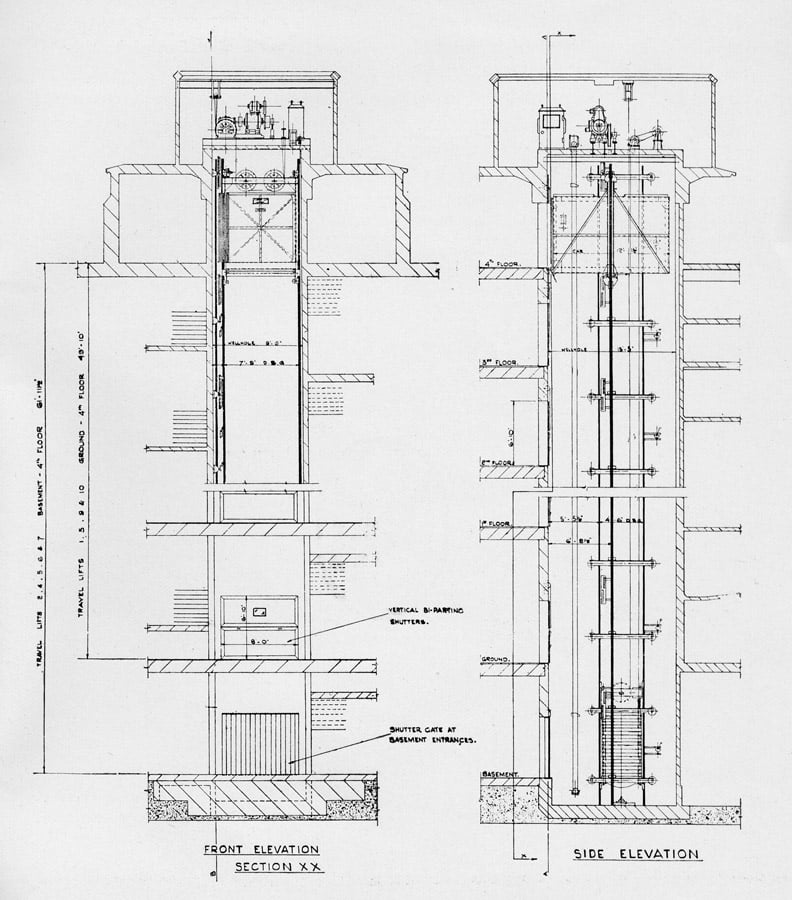

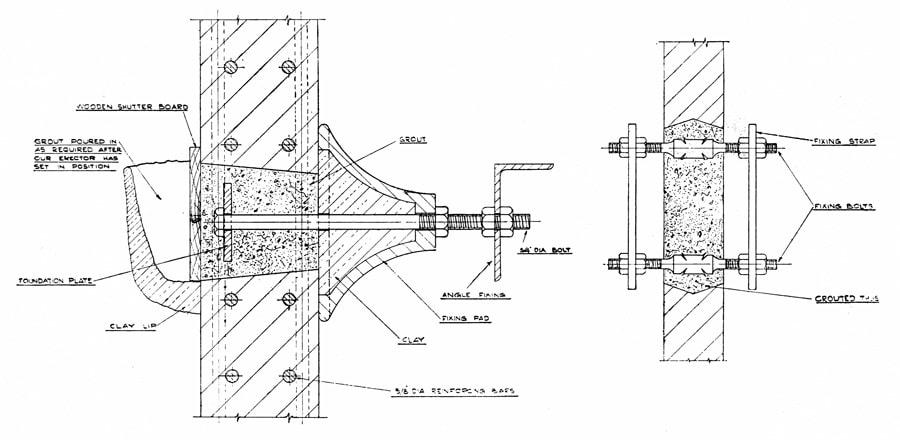

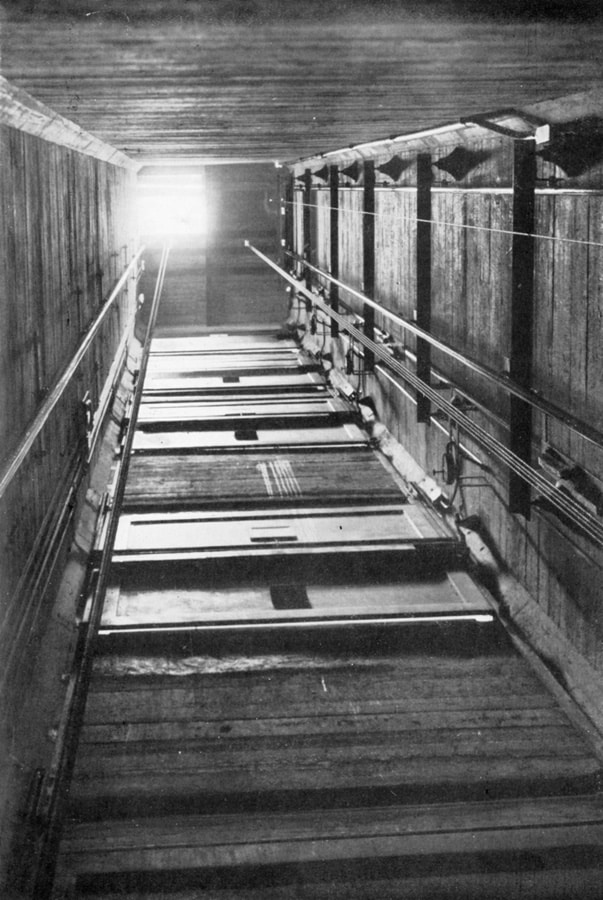

Interestingly, the author chose not to discuss the technical drawings included among the illustrations. Two sections were provided that illustrated the overall elevator installation (Figure 7). These were typical examples of drawings often furnished by elevator manufacturers. However, the brochure also included two detailed drawings depicting the rail clip and bracket installation techniques (Figure 8). One of the drawings also illustrated the “clay lip” that was used to pour grout into the cavity bored into in the shaft wall, and the “wooden shutter board” used to seal the opening.[1] The caption for these drawings described them as illustrating the “general method employed throughout the contract to avoid ‘cutting away and making good.’”[1] Given the building’s pioneering use of concrete, Marryat & Scott may have wanted to show skill in working with this material. This could also account for the inclusion of a photo of a typical elevator shaft that clearly displayed the components seen in the technical drawings (Figure 9).

The brochure’s author concluded by stating that the purpose of their essay was to explain:

“. . .something of the importance of lifts in modern factory buildings in general, and in Messrs. Boots’ new factory at Beeston in particular. They have long ceased to be mere luxuries or useful adjuncts. They have become the principal means of communication for passengers and for the vertical transport of goods. Consequently, they are one of the most vital and important features in the design of every large building, and the installation at Messrs. Boots’ factory will undoubtedly be regarded as a standard, even as the building itself is bound to rank as one of the most important engineering and architectural achievements of the present day.”[1]

While this assessment of vertical-transportation systems was, by 1932, an obvious conclusion, the assessment of the Boots factory and its place in architectural history proved to be prophetic. From its completion to the present, the building has been consistently recognized as an outstanding example of early modern architecture.

References

[1] “The Vertical Transport of Goods at Messrs. Boots’ new factory at Beeston, near Nottingham, Marryat & Scott, Ltd.” (1932).

[2] J.M. Richards. An Introduction to Modern Architecture, First Edition, Penguin Books (1940).

[3] William J.R. Curtis. Modern Architecture Since 1900, First Edition, Oxford: Phaidon Press (1983).

Get more of Elevator World. Sign up for our free e-newsletter.