Toronto Tower Benefits From KONE JumpLift

May 1, 2017

Self-climbing construction-time elevator helps keep mixed-use One Bloor project on track.

To complete one of the most prestigious addresses in Toronto on time, Great Gulf, the developer of One Bloor, chose KONE’s JumpLift construction-time elevator to accelerate work and enhance safety at the downtown building site.

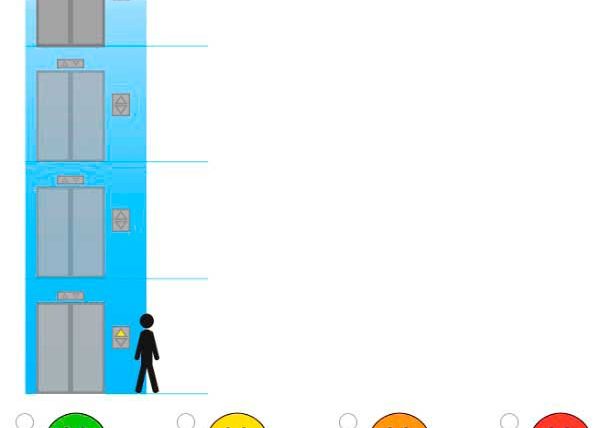

Unlike traditional external hoists, the self-climbing JumpLift system uses a mobile machine room within the building’s permanent hoistway that moves up as the work progresses. Using the permanent entrances, cars and elevator components, the JumpLift moves construction workers and their tools throughout the building at greater load capacities and speeds than are possible with typical rack-and-pinion hoists. Once the building structure is completed, changing over to the permanent elevator is a straightforward matter of installing the final machinery and finishing the material surfaces of the elevator car, landing doors and signalization.

Two KONE JumpLift elevators were used during the construction of One Bloor, a 79-story (including a three-story mechanical level), 257-m-tall mixed-use development. Traveling at 4 mps, the KONE JumpLift runs four times faster than a traditional external construction hoist, significantly reducing the time needed to deliver workers, tools and materials to where they are needed. A post-construction joint analysis by KONE and Great Gulf showed an estimated savings of 80,000 man-hours on the project.

Perhaps just as significantly, the JumpLift helped solve two of the project’s other challenges: the building’s wavy design and the often-unpredictable Canadian weather. Irregular architectural features of a building’s façade can present challenges for external hoists, as can rainy, snowy or windy conditions. Thanks to its location inside the building, the JumpLift system is immune to these situations.

KONE has experience installing JumpLifts at sites in other parts of the world, but One Bloor marked the first time the technology was used in North America. The JumpLift presented Great Gulf with pioneering solutions in design and construction for the project, allowing it to be completed in less time, safely and efficiently.

KONE solutions used on One Bloor:

- Two JumpLift construction-time elevators

- Six EcoSystem MRTM elevators

- Four MonoSpace® elevators

- One EcoSpaceTM elevator

- Two TravelMasterTM 110 escalators

Get more of Elevator World. Sign up for our free e-newsletter.