VFD Braking Resistor Protection

Jul 1, 2021

In this Product Spotlight, your author introduces a new safety feature allowing elevator drives to monitor for braking failures.

KEB has introduced a new safety feature that allows the F5 Elevator drive to monitor for short-circuit failures within the drive’s braking transistor. When properly connected, this internal monitoring board can prevent external damage to braking resistors that can pose a fire hazard if overloaded. The internal monitoring board is standard on all G-, H-, R- and U-sized housings for F5 Elevator drives.

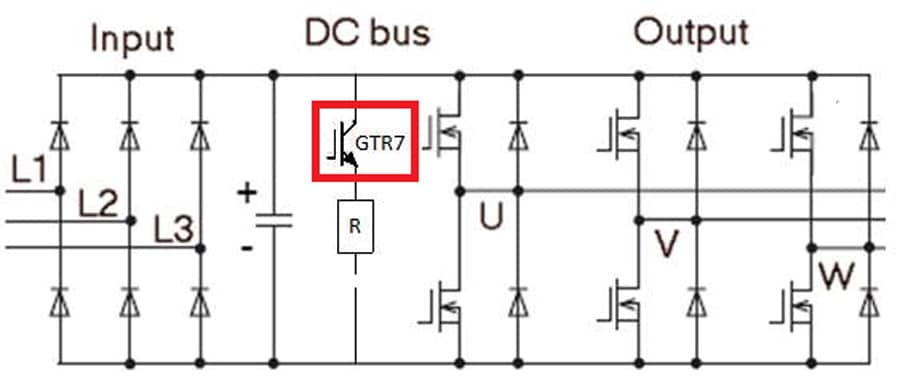

Braking resistors are connected in a series to the drive’s braking transistor (GTR7), which is connected to the DC bus and typically sized for intermittent (not continuous) duty. This means that if the drive’s braking transistor (Figure 1) fails with a short circuit, the external braking resistors will have constant current flow via the drive’s DC bus. This can result in damage to the resistors, as well as create a fire hazard.

To properly protect the braking resistor during a variable frequency drive (VFD) braking transistor short circuit, power must be removed from the braking resistor or VFD itself. This is typically done by placing a contactor between the VFD and braking resistor or in front of the input of the drive. This contactor can be controlled by a temperature-monitoring circuit located on the dynamic braking resistors. During a braking transistor short, the resistors will become directly connected to the VFD DC bus and begin to heat up, triggering the temperature-monitoring circuit, which then opens the contactor. While this method is effective, it can cause entrapments and is prone to nuisance trips if the temperature circuit is not properly calibrated. Additionally, the resistors must heat up for some time before the temperature sensor triggers, which could pose a hazard.

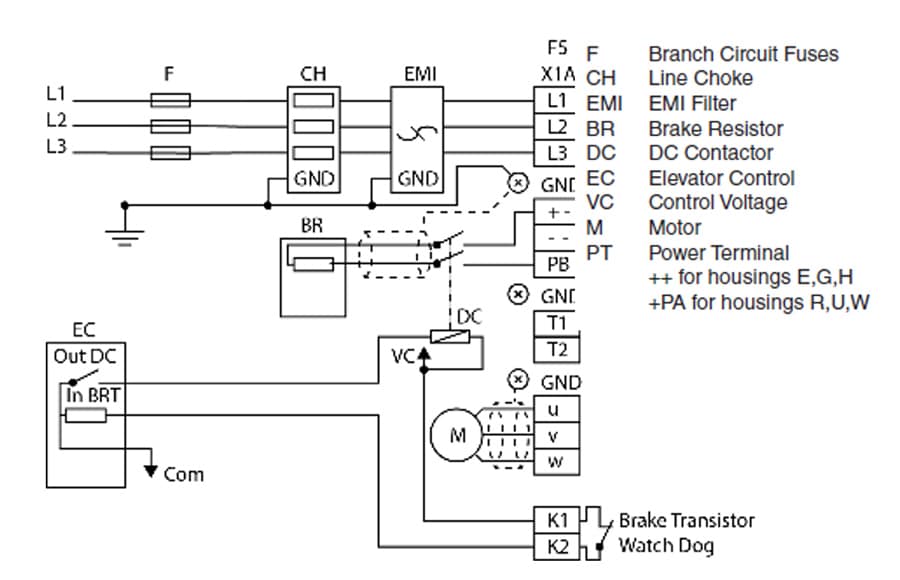

KEB’s internal braking transistor monitoring board (Figure 2) eliminates the need for a temperature-monitoring circuit on the dynamic braking resistors. When a braking transistor short is detected, the drive will open a normally closed pilot contact labeled K1/K2. The K1/K2 terminals can be connected to the elevator controller, which can be programmed to monitor the state of the contact and determine how to respond. If a short circuit is detected during a run, the controller can respond by finishing the run, letting passengers out and opening the contactor, taking the car out of service and preventing an entrapment. The drive will not display a fault if the braking transistor has shorted. The K1/K2 contact must be monitored by the elevator controller for proper implementation.

Power can be removed from the braking resistors during a braking transistor failure in one of two ways. The first option allows only the braking resistor to be disconnected from the drive circuit. This is accomplished using a DC contactor connected between the drive and braking resistors (Figure 3). When a failure occurs, the controller can open the contactor, stopping current flow through the resistors.

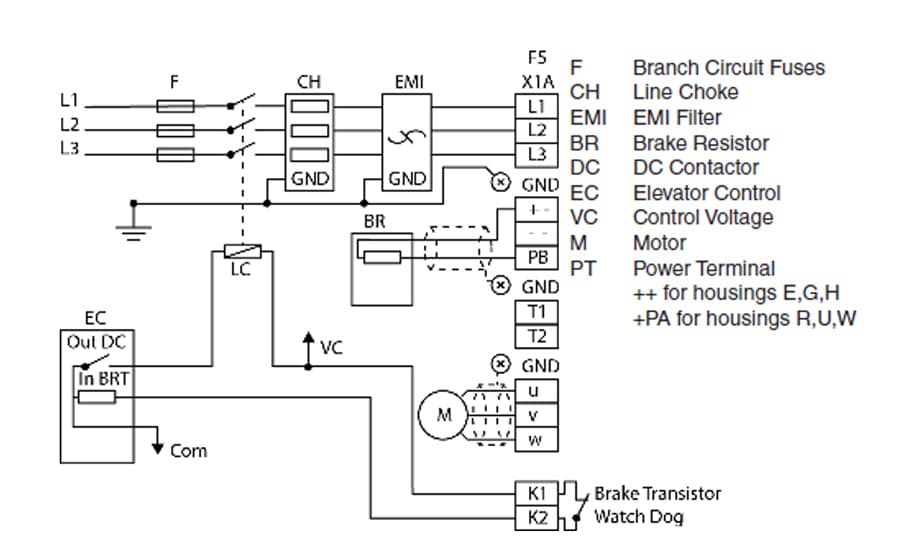

The second option disconnects the incoming voltage supply to the drive. In this scheme, the controller can open a line contactor connected between the supply voltage and the drive’s input, thereby cutting power to the drive (Figure 4). Again, should the failure occur during travel, the controller can bring the car safely to the floor before shutting down.

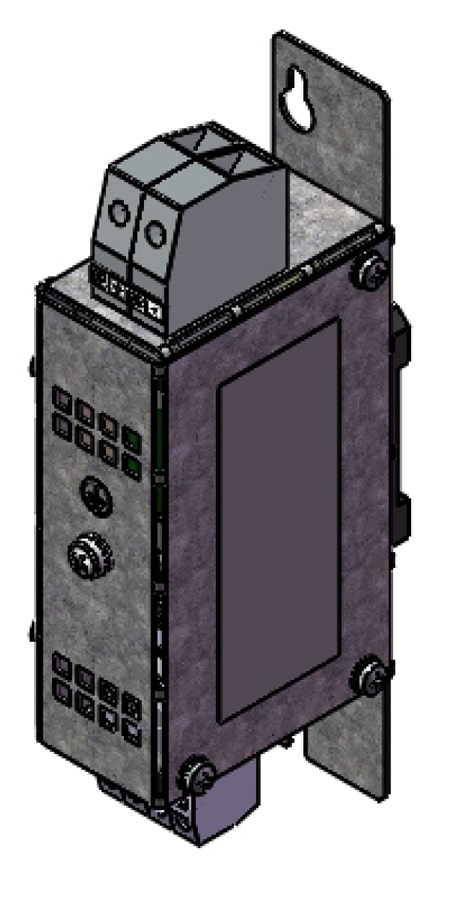

KEB also offers a braking transistor monitoring board that can be externally mounted in the control cabinet (Figure 5). This solution is useful for existing jobs that do not feature the internal monitoring board and for the smaller D/E housings of the F5.

The principle of operation and control schemes is the same. The module is connected between the controller and the drive. The drive can supply power to the module via its 24VDC supply, or an external 24VDC supply can be used. The module’s BR+/BR- terminals are connected across the drive’s braking transistor terminals at ++ and PB to monitor the braking transistor. An external terminal block is required to accommodate the braking resistor and BR+/BR- module connections. The controller can again connect to the K1/K2 terminals on the module and can control the external contactor in the chosen control scheme.

Get more of Elevator World. Sign up for our free e-newsletter.