ThyssenKrupp unveils MULTI, a ropeless, maglev system with multiple elevators traveling both vertically and horizontally, during event in Essen, Germany.

November 27, 2014, could prove to be a significant date for passenger lifts, for it was on this day ThyssenKrupp Elevator introduced its MULTI elevator system. The system is particularly notable because it has no ropes and moves people through a building in numerous lifts on a new, modular guide. Its engineering is based on the company’s wealth of experience regarding linear drive technology, and, when linked with many of the safety and control features used in ThyssenKrupp Elevator’s now well-understood TWIN® system, which consists of a pair of elevator cabs traveling independently of one another in the same shaft, MULTI can be considered an exciting possibility.

Although the announcement comes at an early stage of development, ThyssenKrupp Elevator demonstrated its intention and commitment. Indeed, the new high-rise test tower taking shape in Rottweil, Germany (ELEVATOR WORLD, June 2014) is an important piece of the puzzle: The company plans to have MULTI installed and working in the tower in 2016.

Importantly, this type of system will enable passengers to be transported horizontally and vertically, so the whole dynamic of a high-rise development can be rethought by architects and developers no longer restricted by the weight of the hoisting rope or the height and shape of a building.

“What goes ‘round comes ‘round.” This comment, uttered at the start of the day on November 27, turned out to be very incisive. ThyssenKrupp Elevator invited key media members and lift specialists to an event at company headquarters in Essen, Germany. They were greeted by guides, who led the way to a number of significant features the company wanted them to experience.

Room of Silence

The first experience was the “Room of Silence,” where employees and guests are permitted to sit quietly and think. This room is a very interesting component of a modern building and the entrance was certainly understated – a standard glass office door in an atrium. After a walk along a narrow, tall corridor the space opened to reveal a void with a steel-lined shaft at its core. Guests sat in the core and listened to a guide recount the story of how the Room of Silence came about. Guests learned the space is well used by the ThyssenKrupp community to sit and gather their thoughts or meditate.

Strategic Physical Layout

The second experience allowed guests the opportunity to examine an architect’s model of the complex to see the scale of the headquarters set in a recreated, outdoor park. On a chilly, cloudy day, guests were informed that one of the key features of the complex’s design is its campus-like structure, allowing various ThyssenKrupp business sectors to interact. The guide then led guests through the complex, passing the old Krupp gatehouse on our way to the next highlight.

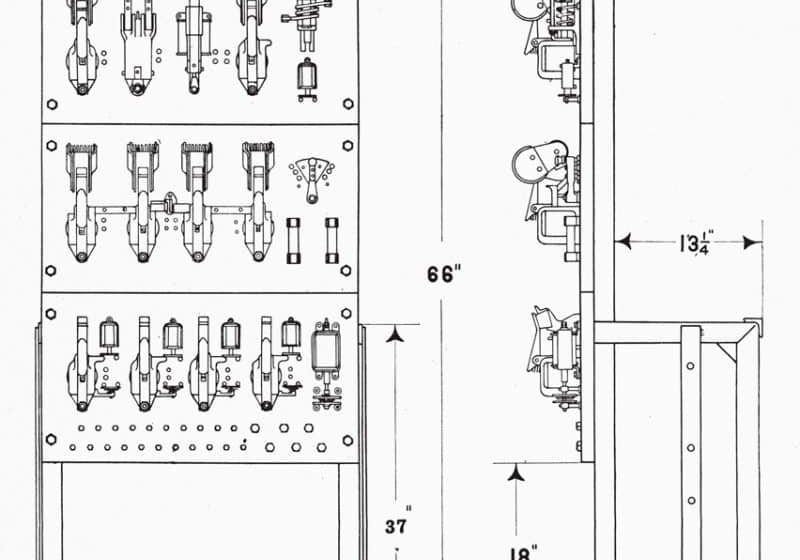

1939 Paternoster

The third experience was indeed a treat, for guests were able to see and ride the 1939 paternoster lift system in one of the old Krupp office buildings. There are very few of these installations left in the world, so this was an experience not to be missed. This working example serves nine floors and was made in Hamburg, Germany, by Friedrich Kehrhahn.

The first paternoster, or cyclic lift, was installed in the Oriel Chambers in Liverpool, U.K., and designed by the influential architect Peter Ellis in 1865. A similar system, designed by inventor Frederick Hart, was subsequently produced by J. & E. Hall in Dartford, U.K., in the 1880s. Examples of the paternoster can still be found in many parts of Europe. The system continued to be installed up until the 1970s, when it was deemed unsafe. It is worth noting that the Arts Tower at the University of Sheffield in South Yorkshire, U.K., still has the largest working system, which serves 18 floors. It can carry 50 people to the top of the building in 9 min. A paternoster’s handling capacity was clear for all the guests to see, and, in hindsight, pointed to what was to come.

TWIN in Action

The fourth experience was a presentation of the TWIN system in ThyssenKrupp’s Q1 (The Cube) building, where guests could see two lifts moving independently and safely in the same shaft. This is always interesting to see, and, in an open atrium, particularly dramatic. So, with the “experiences experienced,” it was back to the main presentation room for a quick lunch in advance of the main announcement.

On the stage in the main presentation room, Luis Ramos, ThyssenKrupp’s head of communications for elevator technology, invited ThyssenKrupp Elevator CEO Andreas Schierenbeck to the stage. Schierenbeck presented the case for a new lift system that could provide the flexibility and capacity required in modern cities. Global urbanization presents a growing challenge to architects and lift designers, he said, so a new approach to buildings’ internal transportation systems is required.

Schierenbeck asked what if a new concept could be developed that takes into account the following factors:

- ThyssenKrupp’s experience developing the linear drive for the Transrapid maglev train

- Handling capacity of a paternoster lift

- Safety technology implemented in TWIN

- Numerous, ropeless cars all traveling in one shaft

Such a concept is being developed, he said, and it is MULTI. Schierenbeck said he felt it was particularly important to point out MULTI has no height limit, and capacity can be added or reduced as needed. This, in essence, means architects and developers can incorporate a people-moving system into buildings of any height or shape.

ThyssenKrupp Elevator’s head of R&D Patrick Bass (now CEO of ThyssenKrupp North America, Inc.) continued the announcement by showing the audience the proposed MULTI system as envisaged by the company’s R&D team. MULTI will be further developed over the next few years prior to installation in the test tower in 2016, he said. There, three 100-m shafts will be used solely for the MULTI system. Before that and by the middle of 2015, a 1:3 scale model will be made at the ThyssenKrupp Elevator Innovation Center in Gijón, Spain, to test exchanger modules, service cars and autonomous running of the cars.

Using graphics, Bass illustrated a number of design elements. Crucial to the concept are the linear drive units on the back of the cars that can swivel to allow for both horizontal and vertical travel. The modular nature of the guidance and the integral linear drive shrinks the shaft area, in turn optimizing a building’s usable floor space. Also, the modular design can greatly speed system installation and allows for use even during a project’s construction phase.

A question-and-answer session closed the event with four senior executives present. Schierenbeck, Bass, ThyssenKrupp Elevator Head of Research Markus Jetter and Ramos all provided great input during this session. As one might expect, audience members made inquiries well after the session ended.

Audience members were assured funding had been secured and the technology proven, so now it is a case of implementing the design and testing the system. New, lightweight materials are also being evaluated to offer MULTI cars with a number of different finishes without affecting performance.

Get more of Elevator World. Sign up for our free e-newsletter.