A Survey on the Effects of the 2011 Van, Turkey, Earthquakes

Jun 1, 2012

This report on the effects of earthquakes on elevator systems and those systems’ susceptibility to earthquakes includes data from a three-day (December 25-27, 2011) investigation of elevators in Erci s¸, Edremit and the city center of Van (all in Turkey). During the survey, the inves-tigation of elevators was performed with the guidance of Van elevator company Ahtamara Asansör. Traction ele-vators visited were randomly chosen for the investiga-tion. Because there were not many hydraulic and ma-chine-room-less (MRL) elevators in the region, information on these installations was obtained from servicing firms.

The most well-known and important seismic threat in Turkey is from the North Anatolian Fault, which has a long history of producing damaging earthquakes. The Oc-tober 23, 2011, earthquake, which had a magnitude of 7.2 Mw, had a compressional focal mechanism and occurred in a region where three plates intersect: the Arabian and Eurasian plates are converging, and the Anatolian micro plate is diverging.

The earthquake and its aftershocks affected much of eastern Turkey, demolishing hundreds of buildings and burying numerous victims under the rubble. Erci s¸ , a town near Van, was the hardest hit by the violent shaking: at least 55 buildings were destroyed, 45 people died, and 156 were injured in this town alone. Most of the buildings that collapsed along the town’s main road were residen-tial, raising the number of fatalities. The second earth-quake, with a magnitude of 5.6 Mw, hit the region on No-vember 9, 2011. Its epicenter was at Edremit, only 16 km from the city center of Van. It caused comparable building damage.

Van Earthquake

October 23, 2011, Earthquake

The first Van earthquake was at a magnitude of 7.2 Mw. It struck eastern Turkey near Van on October 23, 2011. The village of Tabanlı was the epicenter of this temblor, which cost the lives of 220 people and injured 1,090 others.

It occurred at a shallow depth of 20 km, causing heavy shaking across much of eastern Turkey, with lighter tremors occurring across neighboring parts of the South Caucasus and Levant.

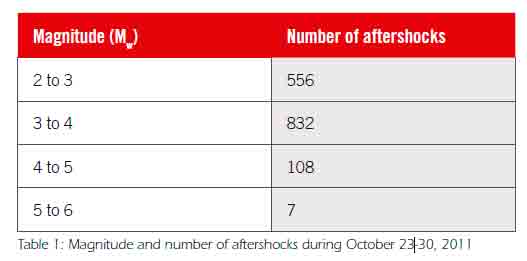

Two aftershocks in Ilıkaynak and Gedikbulak villages, of respective magnitudes of 5.4 and 5.5, in addition to thousands of other aftershocks, were recorded in the Van region. As of October 30, 2011, 1,561 aftershocks above the magnitude of 2 Mw had been recorded (Table 1).

November 9, 2011, Earthquake

Another earthquake with the magnitude of 5.6 Mw and a depth of 9.4 km hit near Van on November 9, 2011, causing 40 deaths and hundreds of injuries. The earth-quake toppled 25 buildings, most of which had already been evacuated following the previous month’s earth-quake.

Impact and Damage

The two earthquakes killed 604 and injured 4,152. At least 11,232 buildings in the region sustained damage. Of these, 6,017 were found to be uninhabitable, leaving at least 60,000 people homeless. In the city center of Van, 100 people were confirmed dead, and 970 buildings col-lapsed in and around the city. The death toll was caused primarily from building collapse in urban areas. In Ercis¸ and the city center of Van, most buildings are between two and seven stories high. Most buildings are 10-20 years old, though almost as many are less than six years old. While the majority of structures in the city center of Van sustained either no or light damage from the temblors, most buildings in Ercis¸ suffered some form of damage, with many (at least 50) collapsing.

Elevators in Van

Most elevators in the Van region are of the con-ventional traction type, with very few hydraulic and MRL elevators. In order to have a clear idea about the susceptibility of different elevator types to seismic shakes, conventional traction elevators were chosen for the investigation, and hydraulic and MRL type elevators were visited. Twenty-seven elevators were evaluated in the report (Figure 1).

Elevators in Erci¸s , Van

In Erci s¸, Van Yolu Caddesi was the most affected ave-nue from the earthquake, where four damaged buildings and their elevators were investigated. Damages observed at these elevators were identical. The local servicing firm, Ahtamara Asansör, also reported that a majority of the elevators were in the same state. Additionally, a primary school beside Van Lake was visited, and its lift was exam-ined. The main results of this work are:

- The landing doors were swing type in operation and in good condition.

- Counterweights were above the cars by comparison.

- Most (four of five) counterweights were derailed.

- Traction machines were intact.

- Hoisting ropes were lying on the sheaves.

- Some counterweight-frame guide shoes were broken.

- Some guide rails (counterweight side) were twisted.

- Many brackets were bent.

Elevators in Edremit, Van

Four elevators with five stops were examined at Van Ihtisas Hospital in Edremit. Out of two healthcare eleva-tors, one hydraulic elevator and one dumbwaiter, only an emergency service elevator was in operation. The hy-draulic elevator and dumbwaiter had been out of service before the earthquakes. The five-story building escaped with only slight damage. These installations were deter-mined to have been of poor quality, yet the damage from the shakes was not serious. This can be explained with the building being low rise and built upon a ground struc-ture that attenuates the intensity of shakes. The main re-sults of this work are:

- No counterweight derailments

- The landing doors were center opening, and some had problems.

- Traction machines were intact.

- Hoisting ropes were lying on the sheaves.

- Many brackets were bent.

- No damages to the hydraulic elevator were found.

- The hydraulic elevator’s safety gears were engaged.

Elevators in the Van City Center

Two hydraulic elevators, five elevators with traction machines and two MRL elevators were investigated in the Van city center. Additionally, one newly opened, evacu-ated hospital was visited. Here, there were three MRL traction machines and four elevators with machine rooms. All the MRL elevators were panoramic and served seven floors. The main results of this investigation are:

- The center-opening landing doors were jammed and stuck.

- The traction machines were intact.

- Most hoisting ropes were lying on the sheaves. One MRL unit had broken ropes.

- Hoisting ropes hung from their brackets.

- Some guide rails (on the counterweight side) were twisted.

- Many brackets were bent.

- The units were totally out of service.

- Pieces of the counterweight fell on the car.

Telephone Survey

A telephone survey with most known local elevator companies in the Van region was also conducted to validate our results. Their servicing activities on damaged elevators showed similar findings to our observations. The build-ings where repairs were performed by the servicing firms were undamaged or slightly damaged yet still habitable.

We attempted to visit two additional elevators but were refused by the authorities for security reasons, since the units (one in Erci s¸, another in Edremit) were installed in governmental places. They were identical, with three stops, and a 630-kg capacity with 0.63-mps contract speed. These units were reported by their servicing firms as undamaged and in operation after the quakes. They had only required valve adjustments (Figure 6). The ser-vicing firms were also asked about the most-frequently encountered damages, such as counterweight derail-ments and broken guide shoes, as well as the number of service visits thus far (Table 2).

Among the most observed hazards were pieces of counterweights falling on the car, twisted rails and bent brackets. Only in five cases were there hoisting ropes out of their sheaves, mostly caused by derailed counter-weights under the attempts of using damaged elevators.

There was no record on entrapments after the initial earthquake, because these are normally handled by local residents. Though there was an extraordinary number of aftershocks, entrapment was not mentioned as a problem, since most buildings in the region had been evacuated due to fear or severe damage.

Observations of Damaged Elevators

None of the elevators examined had seismic detectors, and all car and counterweight frames were equipped with sliding guides. The general assessment of the observations on the damaged elevator systems is as follows:

- Most hoisting ropes remained in their position over the sheaves. There were only five (of 261) reported cases where the ropes came out of sheaves.

- Counterweight pieces falling on cars was observed and reported as a frequently encountered problem.

- Traction machines weren’t moved from their beams.

- Traction-machine and MRL counterweights came out of their guide rails. The main reasons for their derail-ments were larger bracketing spans and insufficient installation practice that caused bent rails and brack-ets, and broken guide shoes.

- In some cases, hoisting ropes hung from guide-rail brackets and supporting beams.

- No damage was observed or reported among hydraulic elevators.

- Hydraulic elevators’ drive units were in good condition and operable. No oil leakage related to the shakes was observed. Hoses were used for cylinder connections in all cases.

- Most elevator systems used swing-type landing doors, and nearly all of these were in good condition, even in heavily damaged buildings. Center-opening doors were generally observed and reported as jammed, with per-manent damage.

- Concrete hoistways protected the floor-door frames and prevented door jamming. It also often served to strengthen the buildings.

Countermeasures for Elevators in Seismic Risk Zones

Although the initial damage to elevators by a strong local earthquake is often not extensive, the displacement of counterweights from guides and wire ropes from pul-leys can be hazardous and expensive if the elevators are permitted to continue operation. Because of their large mass, during an earthquake, the counterweights experi-ence large inertial forces that could damage the rails, brackets or guiding assemblies. To ensure the minimal damage to elevator systems in the event of an earth-quake, the following countermeasures should be taken.

Seismic Switches

Seismic Switches utilize seismic energy to actuate use-ful functions. An elevator seismic switch functions as a normally open switch until a significant earthquake occurs. An earthquake vibration causes the switch to transmit a switch closure to the elevators to continue to the next floor in the direction away from the counterweight.

Counterweights

The counterweight is the heaviest component in an el-evator system. A number of protective methods may be applied to prevent it from becoming disengaged. One method is that box brackets are used to reinforce the counterweight rails so as to restrain the counterweight from swinging. Another method is installing an electrical detector consisting of a displacement ring attached to the counterweight and a stretched wire from the top to bot-tom passing through it near the counterweight’s path.

Guide Rails

An adequately sized guide-rail system will be capable of withstanding a horizontal seismic force of g/2 without damage. The requirement specifies a maximum allowable stress under seismic conditions, which is one-third larger than that allowed under normal conditions. The fishplate requirement ensures a rail system without discontinuity. This would be introduced if a standard fishplate were used.

Brackets

The two guide rails are often linked to each other by intermediate tie or box brackets to avoid spreading of the two rails and to decrease the chance of disengagement of the roller-guide assembly from the rails.

Roller Guides

Restraining plates are required under the roller-guide assemblies to prevent large deformations of roller guides and to prevent them from coming out of the guide rails.

Structural Support Frames

Elevator guide rails and hoistway doors of three-story buildings and taller should be supported with structural support frames. Fastening these frames between the upper and lower parts of the hoistway allows the elevator

to travel up and down in the support frame when it is curved due to horizontal displacement during an earth-quake or strong wind.

Other Protective Measures

In addition to counterweight protective measures, the elevator hoisting machine and other machine-room equipment should be tied down with fastenings sufficient to withstand the expected shock. Rope guards are pro-vided to prevent the ropes from jumping from the sheaves, and the car-to-counterweight compensating-rope system should be tied down with an arrangement to prevent the car and counterweight from bouncing upward during an earthquake shock. The elevator car is also equipped with retainer plates to maintain it within the rails. Anti-snag guards are required in the hoistway to prevent swinging ropes and traveling cables from hanging.

Conclusions

Elevators are vital links of the modern infrastructure system. There is a considerable stock of elevators in seis-mic risk zones. Elevator systems are adversely affected by earthquakes – the higher the magnitude, the greater dam-age incurred to the elevator systems. Counterweight rails and the car guide-rail systems are highly susceptible to earthquakes. The flexibility of guide rails, brackets and roller-guide assemblies strongly affect their dynamic re-sponse to seismic disturbances.

Findings of this survey indicate that in low-rise buildings, conventional hydraulic elevators are the most secure, practical and inexpensive solutions for seismic regions. This is because the conventional hydraulic elevator does not have the counterweight, is supported by the foundation of the building, and uses a hydraulic cylinder that consid-erably dampens seismic shakes. Steel tanks, rubber legs and flexible hoses prevent oil leakage unless the building completely collapses. Easier and safer rescue operation for entrapped people is another advantage of hydraulic elevators in these situations.

For mid- and high-rise elevators, where counterweights are used, related countermeasures should be applied to prevent derailment and make elevators durable against seismic movements. During the investigation, it was no-ticed that most counterweight derailments were mainly larger bracketing spans or installed using weaker prac-tices, though in some cases, derailments occurred with short bracketing spans. Due to the counterweight, more countermeasures should be applied in order to make these types of elevators safer in seismic regions.

It can be ascertained from the earthquake statistics that the number of entrapments depends on the time of day the quake takes place. The initial earthquake may not cause many entrapments, but it is normally followed by thousands of aftershocks, during which the number of en-trapments becomes more pronounced (due to seismic-detection devices and power outages). Thus, the ease of rescue operation for entrapped people should not be overlooked in seismic regions.

There is no doubt safety codes relating to seismic risk zones prevent countless injuries, fatalities and damages. It is certain that millions of U.S. dollars have to be spent on modernizations and applications of improved safety systems, such as major component displacement detec-tion devices, guide-rail keepers, appropriate equipment tie downs, driving-rope sheave guards, seismic switches for building sway (for elevators running faster than 0.75 mps), hoistway snag guards, etc. in order to ensure the minimal damage to elevator systems in seismic zones in the years ahead.

Acknowledgements

The author is grateful to Mehmet Yücelay from Royal Asansör, Kasım Özanlı from Ahtamara Asansör, Blain Hy-draulics and AYSAD (Turkish elevator association) for their support. The following experts joined the survey: your author; Mehmet Yücelay, Royal Asansör, Istanbul; and Dr. Ferhat Celik, Blain Hydraulics GmbH, Germany.

Counterweight pieces/bricks atop car

Counterweights out of their guide rails

Hoisting-rope damage

A deformed guide-rail bracket

Counterweights out of their guide rails

A deformed counterweight frame

Table 1: Magnitude and number of aftershocks during October 23-30, 2011

Table 2: Damage types most often encountered (Data provided by elevator servicing firms in the region.)

Get more of Elevator World. Sign up for our free e-newsletter.