Adams Elevator LifeJacket® Supports Passenger Safety

Jun 1, 2013

While catastrophic failure of hydraulic-elevator systems (specifically in-ground hydraulic cylinders) is not common, these systems can and do fail, leading to serious and costly consequences. As a result, over the last 40 years, the elevator industry has adopted various safety measures to reduce the inherent and somewhat unpredictable nature of these critical components. When we do hear of such hydraulic-elevator accidents, it is not uncommon that the failure mode leading to the accident went undetected by building owners, managers and technicians, even after routine maintenance. A corroding cylinder far below ground, failing pipes or faulty valves can trigger a sudden loss of fluid, resulting in uncontrolled downward movement.

Complying with safety codes, protecting passengers and reducing liability are the biggest priorities in this industry, and John DeVincentis, manager of Coastal Elevator in Jacksonville, Florida, knows one can never be too careful. As an Adams Elevator Equipment Co. customer for much of his 30-year career, DeVincentis depends on the elevator-parts supplier to keep his customers’ elevators in shape with its safety products. The LifeJacket® is one such product designed to improve the safety of hydraulic elevators.

“We received a call from one of our customers, a nursing home, saying that something triggered the LifeJacket locking system,” DeVincentis explained. “When we examined the issue, we discovered that there was a fluid leak in the jack system, and, therefore, a loss of pressure. The LifeJacket product sensed this and stopped elevator operation,” he added.

While it may not cause a freefall, even small leaks from failed cylinders may allow uncontrolled downward movement and can lead to life-threatening elevator accidents. Elevator inspections do not include direct inspection of the in-ground cylinder, and while other critical components may pass inspection today, they may fail tomorrow.

The LifeJacket is designed to catch any unseen or unexpected problems that lead to hydraulic failure — potentially at a cost far below that of cylinder replacements. These issues include valve failure, corrosion, electrolysis, cylinder rupture and various other types of hydraulic failure that result in a loss of fluid and pressure.

A History of Hydraulic-Elevator Safety

Hydraulic-elevator safety has not always been a major industry focus. In fact, before the introduction of the LifeJacket in 1996, all hydraulic elevators were installed without fall-prevention features, because it was considered unnecessary.

Several accidents in the 1960s and 1970s changed this view, and in 1972, elevator codes began requiring new installations to include double-bulkhead cylinders. The thinking was that these could prevent a sudden and significant loss of oil pressure in the event of a single-bulkhead failure.

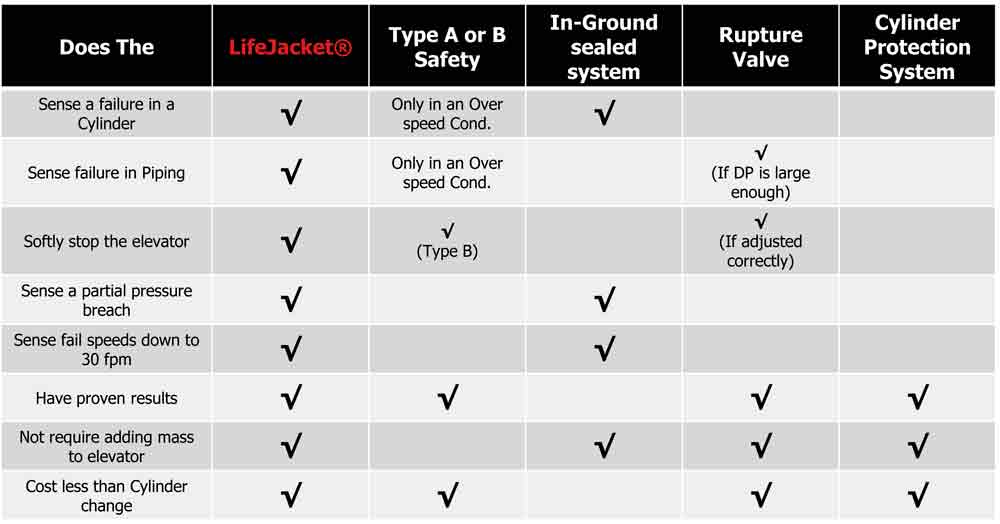

Still, the precaution did not eliminate accidents: subsequent hydraulic failures led to retroactive code requirements in 2004. Codes required one of three safety options:

- A double-bulkhead cylinder, replacing the original cylinder if installed before 1972

- A car safety to prevent the elevator car from falling

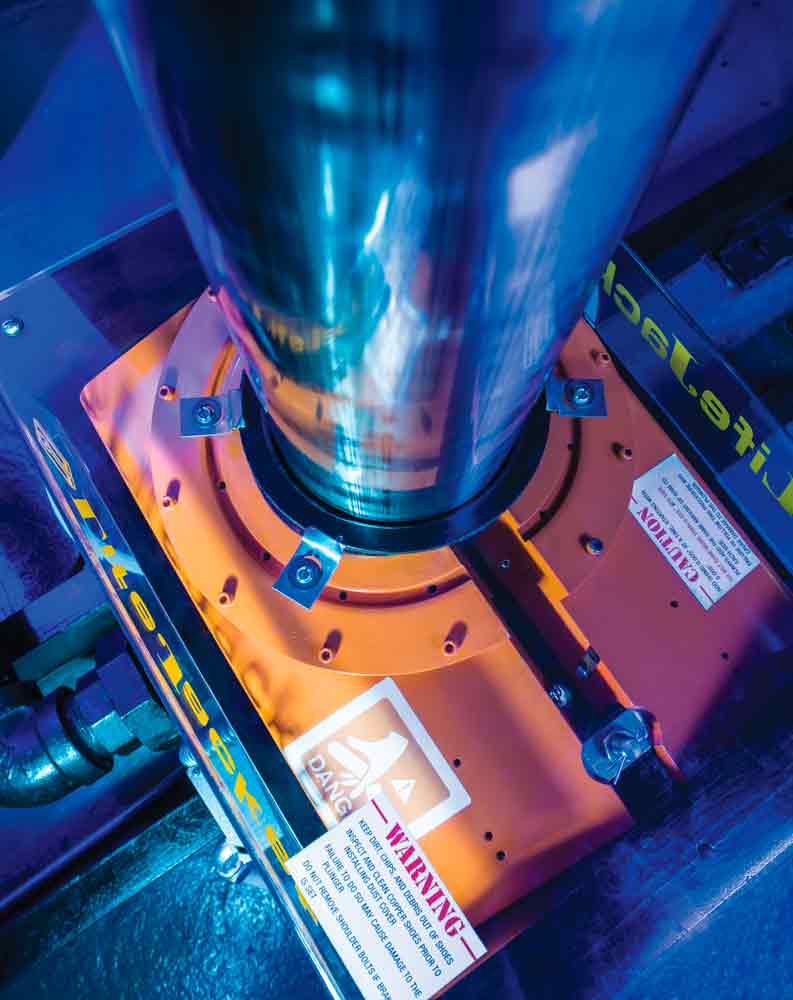

- A LifeJacket system – the only plunger-gripper- style safety device designed to protect the elevator car from uncontrolled downward car movement

The LifeJacket system quickly became a popular option to fulfill code requirements and get some peace of mind. To date, technicians have installed more than 3,100 units that have actuated on demand every time a failure was detected.

The LifeJacket installs above the cylinder head, around the elevator plunger. If it detects any uncontrolled car movement in the down direction, typically due to loss of pressure, it actuates, grips and closes around the plunger, bringing the car to a safe, controlled stop, with no damage to the plunger or the elevator.

The LifeJacket will set if the car exceeds uncontrolled downward speed greater than 30 fpm, if the car exceeds 125% of the operating speed in the down direction, if the system detects damaged or missing operational components or if the system detects a damaged or missing battery or lack of AC power.

It is reusable and can be reset once technicians repair the underlying problem. Should damage to the plunger require complete jack replacement, the same LifeJacket system can be reinstalled with minimal adjustment, provided the replacement cylinder is the same diameter.

DeVincentis’ experience is not the only documented case of a LifeJacket system saving lives. In Santa Ana, California, a LifeJacket system detected an overspeed of 190 fpm at the sixth floor of a building. It actuated and stopped the elevator instantly – just five in. below the sixth floor. Further inspection revealed burst underground piping.

During an attempt to fix a stalled elevator in Columbus, Georgia, a LifeJacket system actuated, locked and prevented the two technicians on top of the elevator from a catastrophic accident. The cause of the failure was a bottom bulkhead that had broken away from the cylinder due to electrolysis.

After a LifeJacket system prevented the fall of a department-store elevator near Atlanta, the mechanic praised the system, committing to recommend it to clients and colleagues.

How Do Other Systems Compare?

Having installed around 12 LifeJacket systems, DeVincentis trusts the product and appreciates the service he gets. “Adams is very responsive. When our technician had questions about resetting the LifeJacket at the nursing home, [Adams was] there to guide him through the process,” DeVincentis said.

Get more of Elevator World. Sign up for our free e-newsletter.