Category 6: Inclined Elevators

submitted by Achim Hütter, Hütter-Aufzüge, GmbH

Meissen is located nearly 25 km northwest of Dresden on the banks of the Elbe River in eastern Germany. Home to approximately 30,000, Meissen was founded as a German town by King Henry the Fowler in 929 and is home to the Albrechtsburg Castle. Built between 1472 and 1525, the Gothic-style castle is regarded as the first to be used as a royal residence in the German-speaking world. It was redecorated in the 19th century with a variety of murals depicting its Saxon history. Today, the castle serves as a museum. The 13th-century Gothic Meissen Cathedral (Meißner Dom) is located on the same hill as Albrechtsburg, which offers a view of the old town.

As Albrechtsburg is one of Meissen’s main tourist attractions, the city wanted to improve accessibility to the hill, which is not easily reached by bus or car. Hütter-Aufzüge GmbH, in collaboration with Schulitz + Partners Architects and Hundt & Partner Engineering Co., successfully designed and installed an inclined traction elevator to meet this need. The elevator is equipped with a glass car, which provides a panoramic view over the hill. Almost without touching the castle, the elevator stops, allowing visitors to enter through the battlements of the castle walls in an effort to prevent structural encroachment upon the historic site. The city’s tendered plan also included a transportation system, which would allow access to the side of the hill.

When considering the installation of an inclined elevator, Hütter-Aufzüge took the following into account:

The importance of adapting to the architectural constraints of the historic site

The implementation of a new design and key components

The use of wireless door systems

Overcoming the logistical challenges of working in a limited area

Elevator Characteristics Support Structure

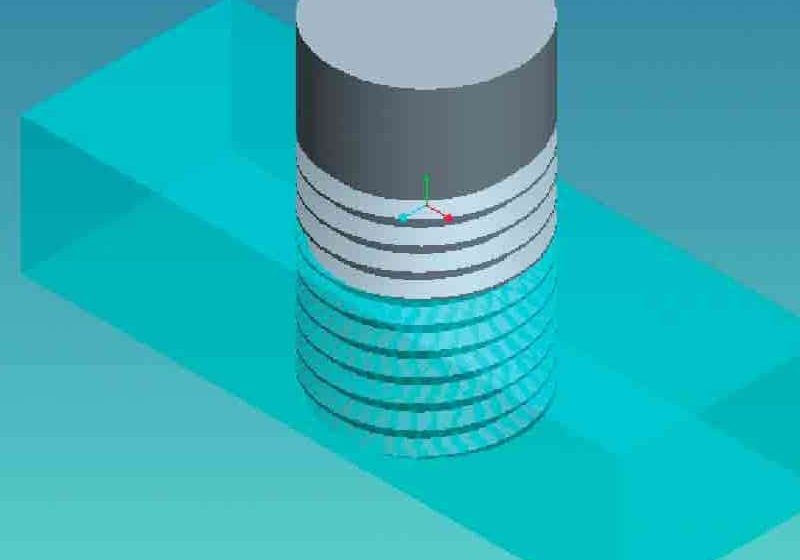

The elevated rail support structure on the lower bearing is fixed, and the inclined support blocks are mounted for displacement in longitudinal direction. The transverse crossbarred support takes the horizontal forces due to wind load on the car. A counterweighted system was chosen for the best energy balance.

Logistics

As the construction site encircled a small area and the elevator parts, especially the support structure (long H-beams), consisted of heavy and bulky material, logistics was one of the major project challenges.

Door Systems

The structure of the building required the integration of two different door systems, one for the lower and one for the upper landing. While the lower landing uses a wireless door system, the upper landing consists of a standard car door combined with a swing door driven by an industrial power operator.

Upper Landing

The swing door is underdriven by an industrial power operator mounted in the walls of the castle. As this combination has not been built before, a valid certificate for the landing-door lock was not available. The entire system had to be designed from scratch to fulfill the requirements of the Notified Body.

Lower Landing

Typically, the cabin and landing doors of an inclined elevator are coupled with a mechanical system that allows the car doors to jointly open the landing doors at every floor. This system envisages a motor and coupling skate for the cabin door, whereas the landing doors are engaged through their own lock.

The installed wireless system allows the control panel to check both cabin and landing doors when they face each other without mechanical engagement. The system also allows communication between the cabin and landing doors, even though they operate with independent motorization and mechanics. However, the control-panel signal only arrives to the cabin door, as with traditional systems.

Once the signal arrives, the cabin door transmits it to the landing door, which simultaneously opens. This is possible due to two peripheral, small-scale and weatherproof infrared receiver/transmitter systems for the data exchange. Due to security reasons, the communication system insulates the motor when the car is running, particularly when the car is not positioned in front of the landing door within the lock release zone.

The communication system is a bidirectional and asymmetrical master/slave type, with the car door acting as master, and the landing door acting as slave. Besides the bidirectional and asymmetrical transmission of opening and closing signals, the system also envisages incoming signals from obstacle-surveying devices (such as photocells), which will synchronously work on both car and landing doors.

The nudging effect when an obstacle is detected is activated on both car and landing doors, and requires the reopening of both doors, even though only one of them is involved in the obstacle detection. The door-lock device is installed on both cabin and landing doors: this means that both doors cannot be manually opened without the opposite key.

Conductor Rail System

For a safe transfer of power and signals from the machine room to the car, a conductor rail system was used. Elevator field specialist Conductix designed the system for outdoor use under heavy conditions. In addition, the safety circuit is transferred through the rails.

De-Icing System

As the system is subject to snow and other weather conditions, the car is weatherproof, the electrical installation has class IP54 protection, and the carriage is equipped with a de-icing system for the rails. A temperature gauge sends signals to the elevator control if the temperature falls to a near freezing point. The elevator then rides slowly up and down to spray de-icing fluid onto the rails. Furthermore, snow brushes are mounted to the carriage in case snow blocks its path. If it snows or the wind blows heavily, the elevator will move to the safe location in the lower station.

Credits

- Builder: City of Meissen

- Project manager: Gerona Pergande

- Architect: Schulitz & Partner

- Project manager: Claas Schulitz and Philipp Heitger

- Elevator consultant: Hundt & Partner

- Project manager: Jörg Fischer and Olaf Gausmann

- Designer and manufacturer: Hütter-Aufzüge GmbH, Germany

- Project managers: Sarah Reisse, Thomas Growe and Dieter Fehse

- Main suppliers: Ziehl-Abegg, Schneider-Controls, SHB and Henning

Get more of Elevator World. Sign up for our free e-newsletter.