Compact Elevator Operators

Dec 1, 2016

Creating more rentable space for property owners

In today’s new-construction and modernization environment, it’s all about compressing time to save money and idealizing space to achieve maximized rental revenues. “To look at this in ‘elevator’ terms,” says Louis “L.J.” Blaiotta, Jr., CEO of Columbia Elevator Products Co., Inc. “The less space our elevators occupy, the more space the building owners have available to rent, and the more quickly and cost efficiently we can deliver these space-saving products, the more competitive and, therefore, happier, are our customers.”

Responding to these market realities has meant seeking ways to reduce elevator shaft size, while remaining code compliant, an industry challenge most recently addressed via the elimination of the elevator machine and controller rooms and substitution of a machine-room-less (MRL) elevator system. Throughout the building structure, today’s MRL units effectively move the mechanical lifting mechanisms and electronic controller systems into the shaft. And, as all space occupied by today’s modern elevator mechanical and electronic systems has already been reduced to optimize rentable square footage for the building owner, the industry, now in a quest for even further space savings, is turning its attention to the elevator system’s architectural components.

Since there is no allowable way to reduce cab interior space available to the riding public without affecting capacity, shaft space savings are achievable by, virtually, only a single option: modifying the operator/track structure to gain as much space as possible in the depth of the car. Explains Blaiotta:

“Up to this point, much has been accomplished via the deployment of our ALURE system, and the Robusta operator, a product we’ve been offering via our partnership with Spain-based Fermator (ELEVATOR WORLD, July 2016). While both of these linear systems produce significant weight reduction and space savings atop the car – an extremely valuable shaft space saver, considering all of the new top-of-car overhead clearance issues generated with the advent of the MRL elevator – neither of these products, in their standard configurations, did anything to reduce the overall depth of the car as compared with earlier harmonic operator installations.

“In the case of the Robusta line, this was intentionally engineered, by design, to mirror the space requirements of the harmonic operator, so as to make it backward compatible for modernizations and enable installation of these linear operators in the preexisting spaces. Specifically, the distance between the door backs and the running clearance is held at 2 in. on both the cab and hatch sides of each landing to mimic what typical harmonic operators employing linkage arms and clutches need in that space. Bottom line, while Robusta’s approach saved a good deal of overhead space, it did not serve to eliminate any of the 4-in. door clutch and pickup roller space between the car and hatch doors to reduce car depth.”

Similarly, Columbia’s ALURE, in its basic configuration, also respected the legacy space requirements of the traditional harmonic operator. Costlier pocket-door versions of ALURE were developed to eliminate virtually all the entrance space in the shaft, but these were limited in the sizes available to bear a full Underwriters Laboratories fire rating, while requiring careful coordination with other trades to successfully interface with the building structure.

The market today is demanding solutions to remove as much shaft space as possible. As the cost of new construction continues to march upward, and landlords seek to devote less and less space to common, non-rentable areas (and look to cut expenses wherever possible), the need has developed for a new, lower-cost operator/entrance combination to minimize the space requirements of the architectural components of the elevator system. With the between-the-doors space the only remaining area available to reduce car depth, it is the focus of the next-generation operator solution, designed to eliminate the clutches and other mechanisms previously occupying that space. Going this route additionally delivers the architectural advantage of using increasingly popular glass doors with a vision area consisting entirely of see-through, uncluttered views.

This approach replaces the space-consuming old-style harmonic system, in which the clutches on the backs of the doors reached out and grabbed the pickup rollers on the hatch doors, with both mechanisms positioned in the middle of their respective doors. Explains Blaiotta:

“Now, in addition to going linear, we’re seeing a drive, which originated in Europe, move the clutch mechanisms and door interlock from the backs of the doors up to the hanger assembly, where wheels, commonly referred to as sheaves, roll in a track. Elevator door hangers are very similar in functionality to the sliding closet doors commonly seen in homes, with a track mounted above and parallel to the doors and wheels attached to the doors, rolling them from side to side in the track. Most critically, without mechanisms on the backs of the doors, the current 5-1/4-in. space between door backs can be dropped down to simply the 1-1/4-in. running clearance, the gap between the car sill and the stationary hatch sill at every floor. This typically results in a net saving of approximately 3 in. in the depth of the shaft for front-opening cabs and up to around 6 in. of space saved in front-and-rear configurations. Plus, while the running clearance can never be entirely eliminated, with today’s faster cars, the trend is toward only a 1-in. clearance, rather than 1-1/4 in., an additional space saver.”

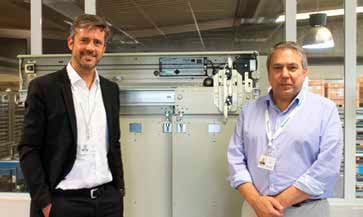

All these benefits are found in a newly developed operator called “Premium,” a further product evolution out of the partnership between Columbia and Fermator, which delivers additional advantages beyond the reduction in cab depth. Explains Eduard Amigó, group sales manager at Fermator:

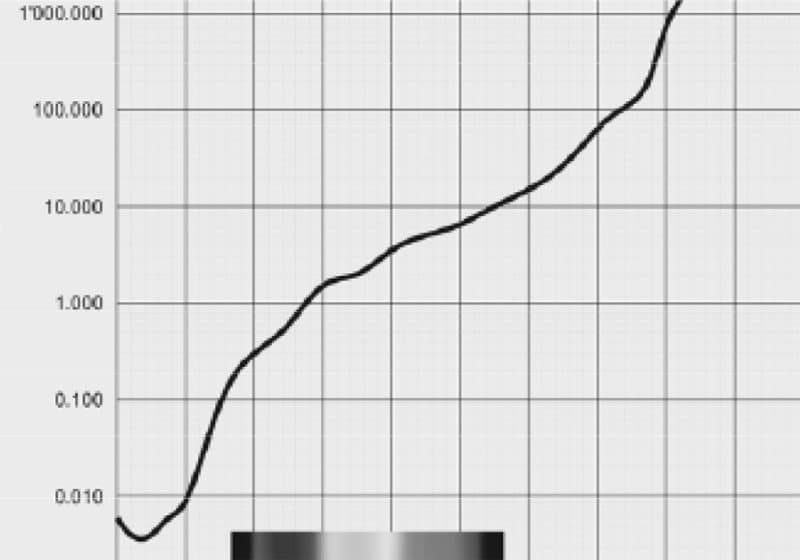

“Since now these linear operators drive the doors from the hanger assemblies — rather than the clutch plate and pickup rollers on the backs of harmonic cab and hatch doors — the back skin of the doors can be eliminated. The resulting door assembly is lighter, easier and safer to install, and makes the entire finished cab lighter; quicker to fabricate; and, accordingly, cheaper. Further, the operator motor includes an encoder, which uses programmed logic to allow it to behave in specified ways. In earlier days, the speed of a harmonic door was controlled by changing the length of the link arm — i.e., the longer the pendulum, the faster it moved — achieved by modifying the linkages to produce the desired performance. With this method, the door could be made to start out slow, then go faster, then slow again as it reached the end of its travel. By contrast, the Premium encoder allows the programming of software that always ‘knows’ where the door is in its travel and causes the door to speed up and slow down to any desired specification.”

These new encoders are closed loop, featuring feedback that tells the motor where it is at any given time. This “smart” system can pick up a very heavy, bronze-relief door in the lobby of a building and move it at a specified number of feet per second. Then, upon traveling to the upper floors – where the doors are much lighter – move all those doors at precisely the same speed but using less force.

Says Blaiotta:

“Some of these doors might be painted, some clad, some with other treatments, not necessarily all the same weight or design as each other, but they will all move at the same speed. Compare this with the old systems, where the doors were pendulum controlled. If these were set to move the light doors at the upper floors at the correct speed, the heavier lobby door would move too slowly, and, if they were set to move the lobby door at the correct speed, the upstairs doors would move dangerously fast. As a compromise, the speed needed to be set at some intermediate level that ideally served neither situation. Now, with this sophisticated system, door operation can be fine tuned for the specific application.”

Explains Jose Rubio, Fermator’s group product manager:

“Beyond comfort, this new Premium system delivers a significant safety factor in the form of a ‘nudging mode.’ Ordinarily, a cab using a light curtain will reverse the door if a rider enters the opening. In the presence of fire or smoke, the light curtain will ‘assume’ there’s an obstruction and not allow the operator to close. When the car is put into Fire Service Mode, it allows the operator to close at ‘nudge speed,’ ignoring reopen signals from the light screen. For added safety, if an obstruction stops the door movement in this ‘natural nudging’ mode, the operator will fully open, then close the door at nudge speed up to the point where it was obstructed, then proceed very slowly through the obstruction zone to verify it has been cleared. Upon a successful full close, the operator will ‘know’ to perform at ‘normal’ nudging speed until Fire Service Mode has been turned off.”

Concludes Blaiotta:

“It’s amazing how much innovative operator design has contributed – and is continuing to contribute – to the ever-evolving needs and societal progressions of the human landscape. Over a decade ago, Columbia first introduced linear operators in its residential ALURE (Automatic Limited Use Residential Entrance) product line. These incorporated critical Fermator-supplied components — such as the encoder, motor and belt drive — and combined with Columbia’s proprietary linear door operator to produce an ideal solution for the lightweight applications typically found in a residential setting where fire-rated doors are not required. Eventually, our customers began requesting the features of ALURE in commercial applications, including modernizations and complete rip-outs where space is at a premium. ALURE is limited to 42 in. wide by 7 ft. tall, while commercial requirements called for much larger, heavier doors. Premium combines all the space-saving aspects of ALURE and ‘beefs it up’ to commercial standards, while consuming meaningfully less space than Robusta. Our new Premium line integrates the best of all these features, and we look forward to rolling out this product in the year to come.”

Get more of Elevator World. Sign up for our free e-newsletter.