Consulting for the Future

Feb 1, 2021

Engineer Luis Sánchez Lebrero says Spanish firm Resuelve Transporte Vertical has built a reputation on completing difficult projects.

by Olga Quintanilla

Resuelve Transporte Vertical, a Spanish consulting firm with more than 27 years of experience in the Spanish and international markets, credits its success to a commitment to excellence, service, honesty and independence. The company says personalized attention to its customers and persistent research aimed at reaching the best technological performance in the modernization of vertical transportation (VT) are its keys to success.

Luis Sánchez Lebrero (LSL), an industrial engineer, has been a partner-consultant for Resuelve since 1992. In this article, your author (OQ) asks him about the difficulties the company has faced because of COVID-19, the demands of customers in response to the pandemic, the transformations VT is undergoing, the importance of energy efficiency and the future that awaits the VT industry.

OQ: How is the pandemic affecting Resuelve in the development of its projects?

LSL: In relation to VT consultancy activity, the projects underway have followed the investment plan, although in some cases, investments were delayed by several months. In other cases, the investor, after evaluating the situation of the pandemic, has preferred to carry out the work of building and modernizing elevators during the pandemic period, because, as there are fewer users in the buildings, inconveniences and complaints have been considerably reduced.

Regarding the methodology of work and development of services, it is obvious there has been an appreciable limitation of face-to-face meetings. On the positive side, the high technological level and current connectivity have made possible the continuation of consultancy services. They are enhancing video conferences with customers and collaborators, optimizing time, providing added value we implemented during this pandemic, and giving us immediacy of communication with engineers of elevator manufacturers so that we can deal with proposals and solutions. Before the pandemic, such meetings were held only in person, which added attendance limitations. Another advantage of remote meetings is they have made it possible to improve the reconciliation of work and family life. This is something that, in Spain, should be encouraged, in view of the experiences in other countries, especially those in Northern Europe.

With regard to investments during the initial phase of COVID-19, some customers revised strategic plans for some projects according to their perspectives of the evolution of the pandemic. However, later all projects were reactivated, reviving the same scope and level of quality seen prior to this contingency.

In relation to the technological equipment of VT facilities, in new projects and in those in the execution phase, customers are demanding integration of systems offering protection against COVID-19. However, it is important to point out that, in some projects before the pandemic, we had already begun implementing many of these technical advances before this situation, for reasons of technological image and hygiene.

In reference to the execution of works in VT facilities, we have observed delays in assembly due to mobility restrictions, as well as cases of COVID-19 infection in assembly companies or among the building’s population. We have also observed worldwide delays in supplies of some materials.

OQ: Which area of your company’s offerings have been most affected by COVID-19?

LSL: We consider that we have been one of the lucky companies, at least until this moment, because we have been able to maintain the development of all our activities and services, including supervision and control visits of work. We hope the rest of the companies and sectors can find the way and realize the support of collaborators so they are able to maintain their activity at 100%, as has been our case.

OQ: Has the pandemic caused changes in customer demands?

LSL: Customers are perceived to be more sensitive to high-performance, highly versatile control systems and the latest touchless technology systems, as a measure of protection against the transmission and infection of viruses, especially SARS-CoV-2, with which we are currently dealing.

We also observe a greater sensitivity to the size of the cabin, which, in Spain, has traditionally been of reduced dimensions, compared to those of other markets. Small cabins make it difficult for passengers to maintain adequate distance. Additionally, one of the measures now frequently implemented is placing limits on the number of people traveling in the cabin to maintain proper distance. Among the most demanded solutions are the disinfection systems of the cabins.

In addition to technological equipment, we consider architectural elements that influence social interaction, such as the rearrangement of users in the waiting halls, changes in traffic studies, a lower factor of cabin occupation, variation of user demand curves, more staggered accesses and different densities of building occupation, in all of our projects.

OQ: In the 27 years of experience of Resuelve, which aspects in the elevator field do you think have promoted a greater transformation?

LSL: In our “elevator world,” the changes, evolutions and transformations have been constant. We must recognize the important research and technological evolution that have allowed the progressive increase of building heights, which have riding distances now reaching almost 1 km. However, we are surprised that, in conversations with some of our customers, they state they do not see major technological changes in the elevator. This means we must improve our communication among manufacturers, service companies and consultants so these advances are perceived to a greater extent by the user.

I can assure that, in the 27 years of experience in elevator consultancy, these installations have improved considerably in security, reliability, accessibility for people with disabilities, energy efficiency, travel experience, peripheral technology, display screens, content broadcasting, integration of elevators with building access control systems, monitoring of the operation of the elevators, etc. We have evolved from elevators controlled by relay technology or basic electronic systems to powerful controllers equipped with AI and extensive connectivity.

In addition, by means of computers or mobile devices, clients have the possibility of communicating with their elevators remotely from any place, having ample and updated information on the state of the elevators, breakdowns, etc. On the other hand, we are evolving to predictive maintenance through the incorporation of Big Data and AI technologies. The introduction into the elevator world of telecommunications, cell phone control, equipment operation monitoring, etc. has required the incorporation of other professional profiles and improved training in these fields.

Not all the evolution has been positive, however. From the consultant’s point of view, we are concerned about the negative drift toward customers basing their choice of elevators almost exclusively on price. This purchasing policy has led some manufacturers to design products that meet this need as a matter of survival in the market. Alternatively, installers offer customers solutions not in line with the intensive use of the elevators in the building. The final result of this situation is a technological “involution.” Some elevators manufactured today are operating in installations meant for more intensive use and are thus registering numerous problems of operation, durability and comfort. As a result, we are participating in projects where almost-new elevators, with three, five and seven years of age, need to be replaced, causing serious inconvenience and economic cost. This is not to mention the ecological impact it implies.

OQ: Our country is safe in terms of VT, but to which causes do you attribute the occasional accidents that occur in elevators?

LSL: Older elevators have significantly lower safety levels compared to those of more modern ones that have the benefit of continuously improved safety regulations. And, in our opinion, it is to these elevators that greater attention and vigilance should be paid.

However, it is important to distinguish between incident and accident. There is a small number of incidents in elevators (not very serious) and an even lower number of accidents (almost anecdotal), although, normally, these cases have a lot of media coverage, as they occur in lifts used daily by the majority of the population and have serious consequences for the occupants.

Today’s elevators are very safe. In statistical terms, in other sectors, there are countless machines that record a greater number of incidents and accidents. Lifts are machines, and, as such, there is no such thing as zero risk. Today’s elevators have countless safety systems. When an accident occurs, it is usually due to a sum of circumstances. Among them are failures in the installation phase or in later modernizations; inadequate maintenance; misuse or negligence; and, to a lesser extent, defects in components. (This is rare, thanks to the current quality controls implemented by the manufacturers of elevators and components.)

The risks endanger not only users, but also technicians. The most common ones are: trapping of fingers (usually in children), uncontrolled car movement with potentially very serious consequences, poor leveling at stops (which causes falls, probably the most frequent incidents) and the fall of technical staff down the elevator shaft. In our opinion, in most cases, the causes of accidents are technical, not human.

OQ: Why does the company say that one of its added values is that “Resuelve reaches where others do not”? How is Resuelve different from its competition?

LSL: Our company offers a highly customer-oriented consultancy, which is our main asset. In fact, we still keep those clients with whom we started working 27 years ago. I believe this is because we strive to uphold principles of excellence, service, honesty and independence. Clients understand a company committing to their interests. We understand that experience and research result in expertise that offers solutions for clients.

To be more specific, we have carried out several high-speed projects with significantly reduced pit dimensions. We have executed cabin sizes in modernizations and rehabilitations, taking full advantage of the elevator shaft and thus gaining cabin capacity in most of them. We have executed atypical dispositions maintaining high levels of comfort. The summary of all this is that, in some cases, due to project needs, we have carried out executions and assemblies that some of the multinational elevator companies, having the support of their best engineers, have withdrawn from, because, although it was very important or of high economic benefit, they considered they could not execute it.

Manufacturers, installers and maintenance companies seek engineering and consulting that is very detailed and presented with a degree of commitment, control and supervision of the work. This situation not only occurs in Spain, but also in the rest of Europe and America, which are other continents where we have worked and provided services.

OQ: What is the future of VT? Which will be most important: aesthetics, safety, sophistication or cost?

LSL: VT facilities will be developed by improving specifications and performance in terms of accessibility for people with disabilities, digitalization, connectivity, predictive maintenance (Big Data), integration with building automation systems, integration with security systems and home automation, interaction with passengers, personalization of travel experiences and aesthetic improvements inside the cabin.

Another technological advance and challenge in high-rise buildings will be from the new technologies that will allow us to overcome the current limitation of maximum ride distance.

Currently, there is R&D underway on user detection systems, including biometric identification systems, which improve accessibility and operation. These systems allow calls to be made to elevators without the need for users to perform any operation. The systems also allow interaction with security and access control in the buildings. Some of these technological solutions, for which we are participating as consultants (and thanks to the support of some of our clients) will be implemented for the first time and will be future references for new projects. Another future bet will be active information systems that will interact according to the situation, the user and their destination, among other factors.

As for what will prevail most, we believe that price will continue to be important for a segment of demand in the elevator sector, but, for some investors who value standing out against their competition, the main objective will be focused on elevators with a greater sophistication, benefits, comfort, customization and singular decorations; in short, to obtain an optimal and singular experience of the trip.

OQ: What has been the most ambitious or interesting project in which you have participated?

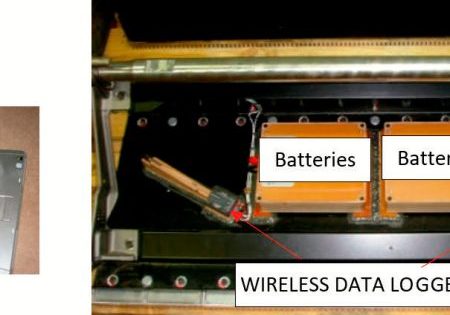

LSL: We have participated in many projects, but those that demand greater technical effort and dedication in work hours are those related to the modernization of elevators. Of each of these modernization projects, we keep a singular memory, since all the multinational installation companies present them as their best executions and take their clients to visit these installations. However, at this moment, if we had to highlight one of them, it would be the modernization project of 12 elevators in Torre Europa in Madrid, a building occupied by very demanding multinational companies. At Torre Europa, all mechanical parts were kept, and all the electronic controls and power parts were replaced by the most sophisticated available. The old DC motors were retained after checking and repairing them. In addition, the installer carried out the work using a control systems combiner (overlay) on old controllers from another manufacturer, which meant that the development of the project was more difficult and ambitious. In fact, the implementation of an overlay was only the second time it was done in Spain. The first time was in another of our projects, years earlier. The result was that our client obtained practically new elevators, while investing one-third of the cost of completely new ones. It was also accomplished in a significantly reduced time, compared to that of a replacement, and resulted in minimal inconvenience to the users.

About Luis Sánchez Lebrero

Luis Sánchez Lebrero has worked as an industrial engineer since 1992. He holds a degree in Civil Engineering from the University of Zaragoza in Spain and began his professional career in the first VT consultancy in Spain, Lift Consult S.L, reaching the position of consultant partner. In 2001, shareholders of Lift Consult decided to diversify the business and create architecture and engineering services company Interbuilding Consult S.L. Sánchez held various responsibilities, including project manager, director of project management, director of facilities management and head of the Coordination Team for Exclusive Building Works. He was appointed operations director until 2004, when he pursued a new professional course in real estate with Lualca S.L., where he was appointed facilities manager and participating in several shopping centers, office buildings and housing projects. In 2006, he became a partner in the society Resuelve Management S.L., which worked in nine principal activities, including VT consulting. In 2018, Resuelve Transporte Vertical S.L. was formed centered exclusively on VT consultancy.

Sánchez serves as VT consultant with a number of real estate companies in Spain, as well as other clients like investors, banks, hotels and architects. Over the course of his 25-plus years of experience, he has carried out projects, audits and inspections of more than 700 VT installations. He has been recognized by such international companies in the sector as KONE, Schindler, thyssenkrupp, Otis and Orona.

Get more of Elevator World. Sign up for our free e-newsletter.