Elevator Car Equipment in the Early 20th Century

Aug 1, 2014

Passenger traffic challenges were solved by a unique blend of machine action and mental acuity.

One of the most successful elevator-equipment companies of the early 20th century was Elevator Supply and Repair Co., which had its main corporate headquarters and factory in Chicago and branch offices in New York and San Francisco. In 1913, the company published an illustrated 48-page catalog that summarized, from its own perspective, the essential equipment required for modern elevator-car operation. The catalog’s text included descriptions of typical operating practices, which provide insights to a world of vertical transportation that relied on trained personnel — operators and starters — to make complex elevator systems function effectively and efficiently. The operational challenges and expectations of elevator service in this period were surprisingly similar to contemporary conditions. However, in place of high-tech, computer-driven solutions, problems were solved by a unique blend of machine action and mental acuity.

The 1913 catalog provided information on “electric signals for passenger and freight elevators,” as well as “auxiliary devices and specialties [used] in connection with elevators.” In addition to elevator equipment, Elevator Supply and Repair manufactured “steel curtains and mechanical equipment for theaters,” and characterized its staff as “engineers and designers of special apparatus for buildings.” The catalog was organized into distinct sections: “Equipment Suggestions for Buildings,” “Flashlight Elevator Signals,” “Annunciators,” “Indicators,” “Special Signal Equipment,” “Auxiliary and Safety Devices for Elevators,” “Theatre Equipment” and “Special Apparatus.” A preface offered an introduction to the catalog, and it concluded with a section titled “Estimates,” which outlined the basic information that should accompany customers’ inquiries about prices. The preface summarized the need for modern signal systems as follows:

“With the advent of the tall office building and the high-speed elevator, elevator signals became an actual necessity. Lacking a simple, precise means of signaling them, a bank of three elevators could not be operated at even moderate speed, and the present 600-fpm machines would be useless. The efficiency of elevator service is limited strictly to the efficiency of the signals, and it is a conservative statement that the equipment of a group of three elevators with the proper signal system adds considerably more to the service than the addition of a fourth elevator.”

The section titled “Equipment Suggestions for Buildings” included a detailed discussion of the equipment required for large office buildings “having six or more elevators.” These buildings required the most complex signaling systems, which included the following components: complete signal systems, indicators, night service annunciators, starter’s signals, electric position indicators, automatic starting signals, telephones, illuminated direction signs and travel recorders. The complete signal system included an “operator’s signal lamp,” an “up-down passenger signal lantern” (located over each elevator door), “up-down push buttons” (located in the corridors), a “controlling mechanism” (located in the penthouse) and “transfer switches.”

The complete signal system was often referred to and marketed as either the “Armstrong Flashlight Signal System” or “Armstrong Electric Signal System.” It had been developed by electrical engineer Charles G. Armstrong (1858-1912), who pursued four elevator-signal patents between 1891 and 1899. The term “flashlight” was applied to this system, because it employed lights that “flashed” or were illuminated to catch the attention of the elevator operator and waiting passengers. When a passenger pressed one of the up/down push buttons, the “first approaching elevator car” moving in the direction the passenger wished to go was automatically signaled.

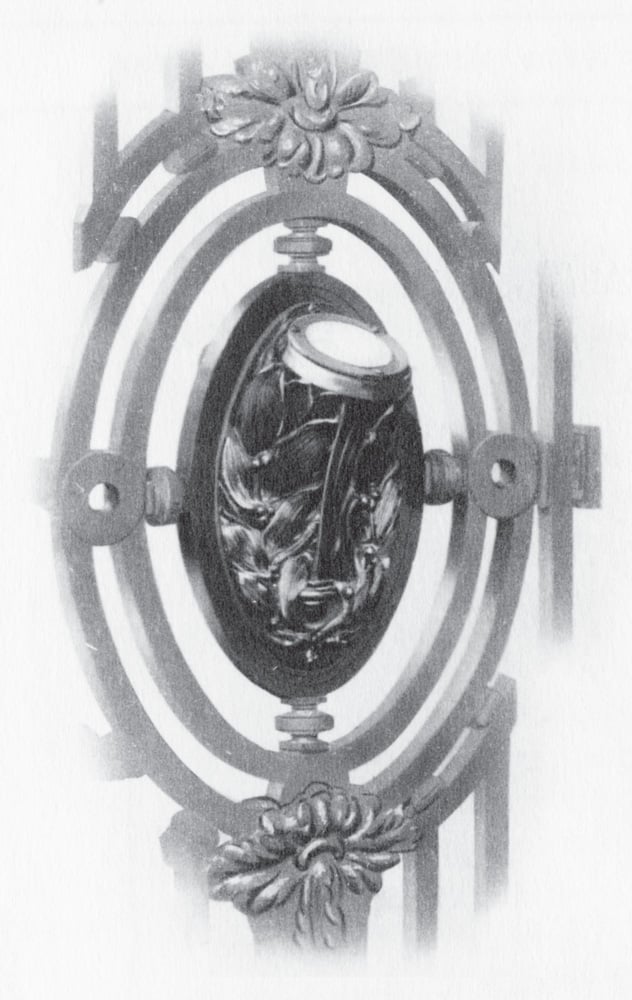

The signal in the car was given by the operator’s signal lamp, which was positioned such that its “flash” could be easily seen by the operator, “whether or not he [were] looking in its direction” (Figure 1). The operator’s signal lamp would flash “a floor and half in advance of the car’s arrival at the landing.” This required the operator to see the flash, determine his position and stop at the second landing past the point where he saw the signal. When the passenger pressed one of the up/down push buttons, the action also automatically illuminated an up/down passenger signal lantern, which was used to attract “his attention and direct him to the proper elevator” (Figure 2). Both signals were “extinguished” when the elevator reached the landing. An additional component typically employed in large buildings was the transfer switch. This allowed an operator, if his car were occupied, to “transfer a signal to the next approaching elevator,” which “relieved the passenger of the necessity of again pushing the button.”

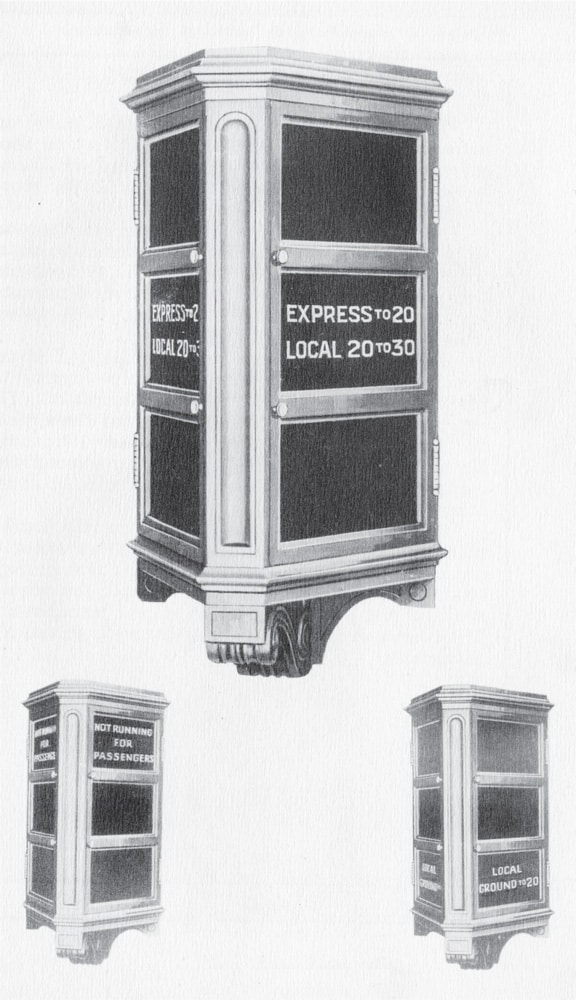

The passenger flashlight signal lantern was typically accompanied by indicators that revealed an individual car’s location to waiting passengers. These were most often “of the clock dial type” and, according to Elevator Supply and Repair, “invariably recommended at the ground floor only.” The catalog included an image of an electric clock dial indicator described as being “somewhat more novel and attractive” than older mechanical indicators (Figure 3). An additional passenger-related device was the illuminated direction sign, which was used to direct passengers to the proper elevators in large buildings. Many of the signs were designed to be able to communicate different messages depending on the time of day, such as “Not Running,” “Local Ground to 20,” “Express to 20” or “Local 20 to 30” (Figure 4).

The majority of the other complete signal system devices were designed for use by the starter, who was charged with managing the elevator operators and ensuring the efficient flow of traffic through the building. These devices included various means of communicating with the operators, as well as ways of monitoring their positions. One popular communication system was the starter’s signal. This consisted of “an ornamental push button plate located in the main corridor convenient to the starter,” which was equipped with a series of push buttons “numbered to designate their respective elevators.” Each button was connected to a buzzer in its designated car, and by using “a simple prearranged code of signals,” the starter could “keep in touch [with] the operators during their travel, as well as dispatch them at the proper instant from the ground and top floors.” Unfortunately, no example of a typical buzzer-signal-code system was given.

Telephones were also beginning to be employed in elevator cars during this period, and, in addition to “giving the dispatcher [a] means of keeping constantly in close touch with the operators,” the catalog also noted the telephone could be used “in case of emergency, accident or when repairs are being made.” Most large buildings also featured an electric position indicator, which consisted of an “ornamental bronze plate” that featured “as many vertical rows of miniature lamp indicators as there [were] elevators.” The starter’s signal and/or starter’s telephone were typically located near the electric position indicator.

Although starters could control their elevators’ movement using the starter’s signal, Elevator Supply and Repair also sold two automatic starting signal systems. The Fuller Starting Signal was a flashlight system. It utilized a panel mounted in the hall equipped with individual flashlights for each car; when an operator saw his car number flash, he started moving. An alternative to the flashlight system was a “motor starting device of the bell ringing type.” This starting device could be set “to give any ringing interval between the limits of 10 and 60 s.,” thus automatically dispatching the cars at set intervals.

The catalog described the fundamental principles of good elevator traffic management as follows:

“One of the most important elements in the efficient operation of elevators is in so dispatching them that the proper interval of headway will be preserved. A bank of elevators operating under ideal conditions will always have an equal number of elevators moving in both directions of travel, and, furthermore, a car will pass any given point in the hatchway every so many seconds; the more exact the interval, the better the service. . . . In a large group of elevators, the cars should be started from the main floor under exact intervals of headway in precisely the same manner as streetcars are dispatched from their starting point. That is, every so many seconds, an elevator should leave the main floor, whether or not it is filled with passengers. . . . Experience soon determines the proper headway for the elevators of a particular building.”

A final and somewhat unique device available to help the traffic flow in large buildings was the disappearing push-button box. This featured a circular cover that could hide the push buttons and replace them with an appropriate message, such as “These Cars Express” (Figure 5). The catalog claimed the starter could remotely and simultaneously control the opening and closing of the disappearing push-button box for all floors that required this service.

While efficient daytime elevator service was critical to a building’s successful operation, nighttime service was equally important. Most office buildings offered only limited elevator access after normal business hours. In the early 20th century, “in practically all office buildings,” it was “customary at night or on holidays, when the regular service is discontinued, to set aside one elevator to answer calls.” These elevators were equipped with night-service annunciators, which combined the operator’s signal lamp with an indicator in the car that featured two miniature electric lamps per floor (white for up and red for down) (Figure 5). The operator’s signal lamp alerted the operator that a call had been made, and the indicator gave the floor number and desired direction of travel. The night-service annunciator could also be switched “in or out of circuit with the same signal push buttons used during the day.” The catalog’s author noted that, prior to the development of this version of the night-service annunciator, “it was the custom to have an entirely independent set of push buttons for night service, with consequent confusion due to the likelihood of the waiting passenger pushing the wrong set of buttons.”

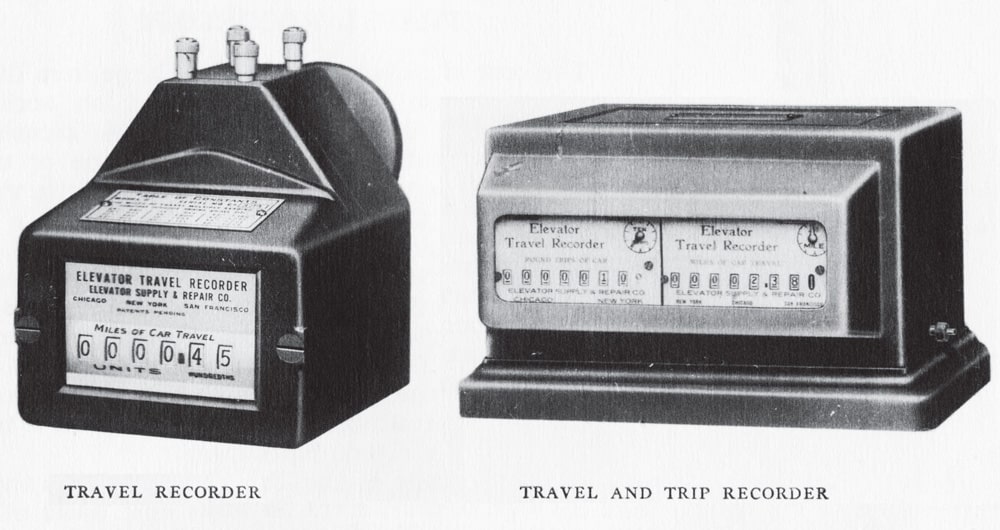

The final piece of required technology was directly related to the expense involved in providing first-class elevator service. However, Elevator Supply and Repair recognized an awareness of the total operating cost an individual elevator over a set period of time was “of little value,” unless that cost was understood on a “unit basis of per mile of travel.” To gather this critical information, the company manufactured two types of “Travel Recorders” capable of measuring elevator travel in units of 1/100th of a mile (with an alleged accuracy rating of 99.9%). The basic model only measured a car’s travel distance, while the more advanced model measured both travel distance and counted the trips made (Figure 7). The latter feature was useful, because it provided “a means of comparison of the individual efficiency of the various operators by indicating whether or not they have made as many trips as the total distance traveled would permit. In other words, it indicates how much travel has been wasted by bad stops.”

This review of Elevator Supply and Repair’s 1913 catalog touched on some of the systems manufactured and marketed by the company that were designed to ensure efficient elevator operation. It also revealed the unique interface between people and technology that was required to make these systems function. This symbiotic relationship was critical in an era where people “drove” elevators and where a human brain guided elevator traffic in large buildings. This review also, perhaps, reminds us that providing quality elevator service in the “good old days” was, in many ways, as complex a problem to solve then as it is today.

Figure 1: “Operator’s Signal Lamp”

Figure 2: “Passenger Signal Lantern” cover

Figure 3: “Electric Clock Dial Type Position Indicator”

Figure 4: “Illuminated Direction Signs”

Figure 6: “Night Service Annunciator Systems with Operator’s Signal Lamp and Floor/Direction of Travel Indicator”

Figure 7: “Travel Recorders”

Get more of Elevator World. Sign up for our free e-newsletter.