Elevators As Communications Systems

Oct 1, 2021

In this History article, your author examines a lesser-known application of VT technology.

The editorial focus of this month’s issue is Communications Systems. While this subject has a rich history and offers many areas of investigation, it is also possible to utilize this topic as a means of introducing a lesser-known application of vertical-transportation (VT) technology. Elevators are, of course, primarily defined as transportation systems — machines that carry passengers to and from specific destinations. However, in the early 20th century, an American company that specialized in intra-building communications systems reimagined the elevator as a system designed to carry documents and other business-related materials between offices. Although dumbwaiters were occasionally used in office buildings and other commercial settings for this purpose, the devices examined in this article were distinctly branded as elevators. This marketing decision allowed them to be distinguished from simple dumbwaiters and sold as unique business communications systems.

Between 1879 and 1881, Massachusetts businessman William S. Lamson developed one of the first systems designed to transport cash and documents easily and automatically among various locations in retail stores. His goal was to eliminate the need for “runners” — employees hired solely for the purpose of carrying materials from point to point. In 1881, he founded the Lamson Store Service Company, which was acquired by the American Pneumatic Service Company in the early 1890s and renamed the Lamson Company. By 1900, their product line included pneumatic tube systems, wire-line cash and message carrier systems, parcel carrier systems and light elevator systems. Figure 1 illustrates a typical wire-line carrier system employed in an office setting, which allowed horizontal interoffice document transport. Pneumatic tube systems were also often used to transport documents horizontally and vertically in large office buildings. However, the carrier’s size and rounded shape required documents to be “rolled up.” Lamson’s elevators allowed documents and other materials, such as ledgers, to be placed flat during travel between offices.

The company manufactured several different elevator types, including cash and message lifts, light hand elevators and a dumbwaiter-type system intended for heavier loads. These products were the subject of a circa 1915 catalog titled Lamson Light Elevators. The cash and message lift was designed to carry “messages, papers and light loads of merchandise quickly between floors.” This system was not, however, intended for use throughout an entire building:

“This lift operates easily between two floors. The car is of wire mesh, with metal frame, and is guided by steel wire guides. The car is attached to the propelling handle through a 4-to-1 pulley system. In other words, the car travels four times as fast as the propelling handle. A catch at the top of the run holds the car in position, and it may be easily disengaged by a pull on the propelling handle. The descent of the car is checked by shock-absorbing springs.”[1]

Two versions of the lift were manufactured: one featured a vertical woven wire basket, 5 X 6 X 12 in. in size; the other model featured a “leather telescope purse” designed to carry cash.[1] The application of normative elevator terminology to this system, including references to a car, is somewhat at odds with its appearance, as illustrated in the catalog (Figure 2).

Whereas the description of the cash and message lift did not include details on its capacity, the account of Lamson’s light hand elevators provided greater operational details:

“This economical and efficient elevator is designed for service between two floors or between a floor and a balcony. It occupies very little space, as it is installed close to a wall or column. It is especially intended for use in stores, offices, factories, banks, etc., for carrying mail, correspondence, orders, documents, drawings, tools and other small articles. This elevator is built for light loads only. The double lift may be used for loads up to 12 lbs. In the single lift the load should not exceed 10 lbs., as no counterweight or governor is used.”[1]

Several versions of this system employed vertically oriented, woven wire cars: the single elevator featured one car, while the double elevator featured two cars (Figure 3). The catalog text stated that “almost anyone can install this type of elevator, as the top and bottom cross braces are simply fastened to the wall by flanged fittings.”[1] The standard floor openings for the single elevator were given as “right to left — 10.5 in. and front to back – 8 in.”[1]

The elevator’s installation guidelines glossed over the potential challenges involved in cutting an opening in an existing ceiling and floor system, as well as the need for safe guards around the floor opening. In fact, the catalog emphasized that all Lamson elevator systems could easily be “installed without enclosures.”[1] Although enclosures could be built, it appears that open systems were more typical. This fact, coupled with the small floor openings, may have lessened the perceived need for guards around the “shaft.” The opening’s dimensions are also specified in a curious manner: from right-to-left and front-to-back, rather than as length and width. The offset position of the cars on the double elevator allowed the cars to counterbalance each other, while the single elevator, like the cash and message lift, did not employ a counterbalance. These elevators used guides composed of steel tubing in place of the wire guides found in the cash and message lift.

Figure 2. Lamson cash and message lift; the “leather telescope purse” is shown in the inset image.

Figure 3. Lamson light hand elevators: No. 107 (left) and No. 108 (right)

Figure 4. Cover, Lamson Light Elevators (ca. 1915)

Figure 5. Lamson light hand elevator (No. 105) installed in Citizen’s National Bank, NYC

Figure 6. Lamson light hand elevator (No. 105) installed in Citizen’s National Bank, NYC

Figure 7. Lamson light hand elevator (No. 105)

Figure 8. Lamson hand elevators: No. 102/100-lb capacity (left) and No. 202/200-lb capacity (right)

Lamson also manufactured a light hand elevator (model No. 105) that more closely resembled a “real” elevator. This system, which was featured on the catalog’s cover, was likely one of their best-selling models (Figure 4):

“This attractive and efficient light hand elevator is designed for practically universal service wherever papers or light loads of merchandise up to 20 lbs in weight are carried between two or three floors. It is used in offices, banks, factories, and commercial and industrial establishments for carrying mail, correspondence and papers, as well as tools, small parts and other light loads. . .The elevator is easy running, a pull on the center cord being sufficient either to raise or lower the car. An automatic latch holds the car at the top of the run, a pull on the hoist rope serving to release the latch. At the lower end of the elevator the descending car is brought to rest easily and quietly by rubber bumpers. It is practically noiseless, as the counter balance weights run inside one of the tube guides, which are made of 1.25-in. diameter, No. 16 gauge steel tubing. . .As the elevator is designed as a self-contained unit it can be installed by any mechanic or handy man with ordinary tools. The tube guides are supported on the lower floor or on a counter or other fixture by flange plates. The upper end of the elevator is extended about 5 ft above the top floor in order to allow the car to be stopped at a convenient height for loading and unloading.”[1]

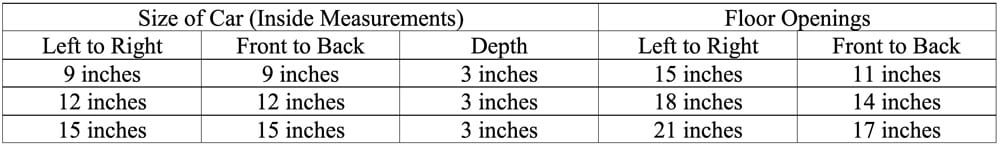

The elevator’s square cars were built of woven wire mesh and were available in three standard sizes (Table 1).

In addition to an image of the full system, the catalog included installation photographs of the No. 105 elevator (Figures 5-7). The installation photographs depict the upper and lower stations of a typical system and reinforce the elevator’s miniature characteristics.

In addition to systems that resembled traditional elevators, Lamson also manufactured dumbwaiters that were marketed as “hand elevators.” The company sold two models, one with a 100-lb capacity and one with a 200-lb capacity. These elevators were described as:

“very easy running and practically noiseless in operation. One of the hand ropes is pulled to raise the elevator, the other to lower it. An automatic brake positively holds the car in any position. Two types of guides are furnished as desired — 2.25-in. diameter No. 18 gauge steel tubing or 1.75-in. square wood. When tube guides are used, one of the guides may be equipped with a speaking tube attachment, a great convenience where supplies or other materials are ordered from another floor. With wood guides a flat counterweight is used, while with tube guides a cylindrical counterweight runs inside one of the tubes. Both types of counterweights are adjustable to counterbalance the car.”[1]

The wooden cars employed on these elevators resembled dumbwaiter cars and typically had two compartments or shelves (Figure 8).

While the counterweights illustrated for use on the company’s 200-lb-capacity unit appear to have met general code standards, the absence of shafts or enclosures presented another code challenge.

The Lamson light elevators were developed and marketed prior to the development of the A17 code (the first edition was published in 1921). Marketing aside, these machines would have probably been perceived by code officials as dumbwaiters. The first A17 code primarily addressed powered dumbwaiters and included only limited references to hand-powered systems, thus the application of the rules to these elevators might have been challenging. Lamson’s elevators did meet the code standards concerning guide rails:

Rule 502 Guide Rails said:

- Guide rails shall be rigidly secured to the hoistway and the joints either tongued and grooved, doweled or fitted with splice plates.

- One set of guides may be used for both the car and the counterweight.

- Hand dumbwaiters having a capacity of not more than 20 lbs and their counterweights shall have guides of wood, metal, metal and wood bolted together, metal tubes or spring steel wires maintained in tension by turnbuckles.

- Dumbwaiters having a capacity of more than 20 lb and a speed not in excess of one hundred (100) ft/min shall have guide rails of metal, wood, or metal and wood bolted together.[2]

- Lamson’s “cars,” however, did not meet general code standards.

Rule 500 Car Construction stated:

- Dumbwaiter cars shall be of such strength and stiffness that they will not deform appreciably if the load leans or falls against the sides of the car.

- Cars shall be made of wood or metal and of “solid” construction. Cars for power dumbwaiters shall be reinforced with metal from the bottom of the car to the point of suspension. Metal cars shall be of metal sections rigidly riveted or welded together. Cars may be provided with hinged or removable shelves.[2]

The code also directly linked car size to capacity. For example: a 100-lb-capacity system required a car with 24 in. X 24 in. horizontal dimensions. Lamson built hand elevators with a 200-lb capacity that employed cars with horizontal dimensions of only 20 in. X 18 in. While the counterweights illustrated for use on the company’s 200-lb-capacity unit appear to have met general code standards, the absence of shafts or enclosures presented another code challenge. Of course, it is possible that officials charged with applying the rules of the new A17 code would have looked at an installation of Lamson’s light elevators, and decided they were really just clever communications systems.

References

[1] Lamson Light Elevators, The Lamson Company (ca. 1915).

[2] “A Code of Safety Standards for the Construction, Operation and Maintenance of Elevators, Dumbwaiters and Escalators,” American Society of Mechanical Engineers, New York (1921).

Get more of Elevator World. Sign up for our free e-newsletter.