EURO-LIFT 2012 in Kielce, Poland

Feb 1, 2013

Held in October, this event saw exhibits from 100 companies from 17 countries.

The EURO-LIFT 2012 elevator expo was held in the central Polish city of Kielce on October 24-26, 2012. The event provided the opportunity to present many lift products to Polish contractors, specifiers and users of lift and escalator equipment. This is particularly important now in Poland, as much modernization and upgrading of lift equipment is required to conform to European Union (EU) directives, along with the surge of new developments initiated by EU membership. Also, the Safety Norm for Existing Lifts initiative is just starting to gain recognition and is now underway in the EU, which is resulting in the need for extra safety equipment on many existing lift installations.

This was the second event organized by Targi Kielce S.A. and its partners EWIT and PALM (Polish lift association) at the modern exhibition complex TargiKielce Exhibition & Congress Centre. Although there is not an international airport nearby, there are road and rail links to both Warsaw and Krakow, Poland, which also afforded the international visitor a chance to see some of the countryside and gain a feel for the development activity happening in the region. Looking out of the train window, it was clear that a great deal of construction on infrastructure, business parks, office buildings, shopping malls, residential apartments and homes has been started. So, upon arriving in Kielce, it was no surprise to see the roads being improved and a mass of construction projects, including further development of the exhibition complex.

Organizers stated that 100 companies from 17 countries were exhibiting at the event. This was encouraging for the sponsors, who felt such support for the event gave it an opportunity to develop. Dr. Andrzej Mocho ´n, president of the Targi Kielce board, stated:

“International companies find Poland as a really attractive, ready market, and this is demonstrated by the fact that 60% of [the] expo’s exhibitors come from abroad. Undoubtedly, EURO-LIFT was the perfect presentation platform for all the latest developments in the lift industry. The product assortment was really extensive, as it ranges from lift equipment and components, drives, cabins, ropes and doors, through controllers, surveillance and safety systems, operation and maintenance systems, indicators, hydraulic solutions, accessories and fitments, finishing with trade publications.”

On touring the exhibition, it was clear the hall was well suited for a lift show, with good headroom and easy access for the exhibitors’ equipment. There was also plenty of car-parking space, hall width and refreshment stands. One of the most important attributes about this exhibition was the presence of many Polish official bodies.

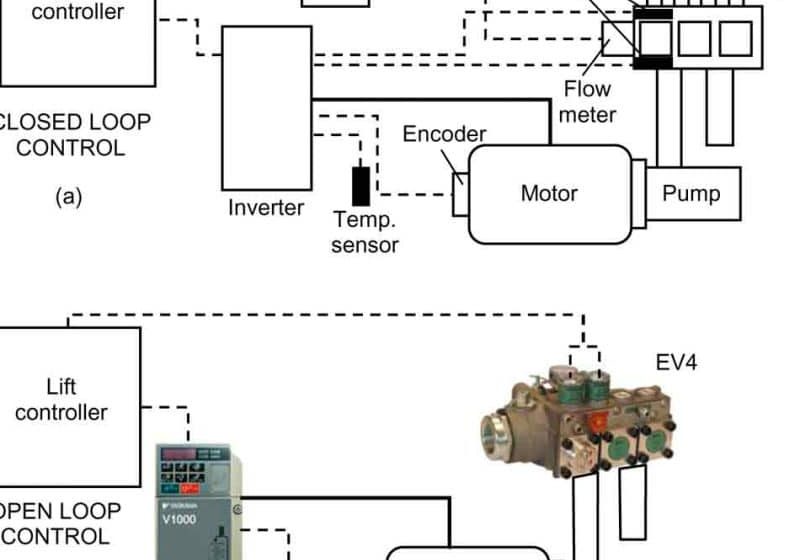

A lift exhibition would not be complete without a working display, and at EURO-LIFT 2012, examples were always catching visitors’ eyes. Working machine-room-less solutions, both hydraulic and traction, could be found and were available as complete packages or as components to make up a bespoke system. However, most components at the show were related to modernization and improving safety. Products to improve leveling or stop uncontrolled movement were of particular interest.

Another important factor in the present world of lifts is the Amendment A3 initiative, which focuses on the energy efficiency of the lift system and the components from which it is made. Attendees could find many references to A3 on the display screens and products for energy efficiency, energy recovery and total lifetime cost savings. It was clear that lift monitoring and efficiency were also being addressed. On the lift control side, there is a need for the system to activate or turn off standby modes without affecting safety, security or traffic-handling capacity. According to design engineers present at the event, it was difficult to see where further energy savings could be made beyond these improvements. The main thought was how and when the implementation of the new standards would actually happen and be enforced. Other questions posed at the expo were:

- How long is the payback time for the capital invested for these energy improvements?

- Is safety really an issue with lift owners?

- From where will the service and maintenance engineers or technicians come to do all this work?

These questions were not answered here and stand to be asked again in the near future.

The other main change to any lift exhibition is the increasing amount of access equipment that can be seen: stairlifts, home lifts and products usually used in a domestic situation. This type of product made up a large proportion of the equipment at the stands at EURO-LIFT. One particular example was of a stairlift set up on a looped track. Visitors could ride on the chair, which turned through 360° as it wound through its course.

Visitors were seen in large numbers on the second day, and exhibitors were generally pleased with attendance on each day, with good contacts made throughout. According to Luc Rivet, secretary general of the European Lift Association (ELA) and general delegate of the European Elevator Association:

“Poland is a surprise to many in the European Union by the strength of its growth, which remains positive, despite the general economic downturn in nearly all other member states. The 2012 edition built upon this good beginning and saw an increase of the number of exhibitors by 15%, reaching 100, with foreign firms occupying half the stands. The exhibition brings together more than 2,000 business insiders and specialists.”

Delegates from Russia, led by Vice-President of the Russian Lift Association Yuri Radin, and those from other Central and Eastern European countries were at the exhibition, and they certainly added to the international nature of the event. An exhibition of this size is very important for both the visitor and exhibitor, as it affords serious professionals time to gain quality information from key engineers and specifiers without the pressure of having to rush to another hall. Quality dialogue can take place, and a greater understanding about what the contractor needs from the supplier or what the client expects from the lift manufacturer can be had. Due to the aforementioned construction in the area, the next EURO-LIFT, to be held on October 22-24, 2014, should present even more positive changes for visitors.

Technical Conference: Safety and Maintenance of Lifts in Poland

The two-day conference was an important part of EURO-LIFT. Attendees heard 10 presentations covering the important topics of safety and maintenance. The conference started each day before the main Euro-Lift exhibition was open to ensure delegates had time after lunch to tour the displays. This conference venue was certainly striking, with the meeting room housed in a dramatic red tube suspended above the main exhibition floor in the expo hall, which was fittingly served by a pair of Schindler escalators.

Day One

Delegates were welcomed to the conference by Mocho ´n and Tadeusz Popielus, secretary general of PALM. More than 40 delegates attended this session, which focused on the maintenance of lifts, with the provoking subtitle “Threats and Challenges.” After the initial introduction, we were shown an ELA safety video, which set the context for the need for maintenance. A safe lift installation has to be well maintained, where competent technicians and proven systems ensure the safest possible use, both for the passengers in the lift and workers in the shaft.

Rivet then gave a presentation that focused on accidents regarding both escalators and lifts, and showed how ELA is gathering accident information to form a reliable database of relevant statistics. Rivet stressed that all companies, regardless of size, should report any accident, so the database can be truly comprehensive. Preliminary results indicated the main causes of accidents to users in descending order:

- Stopping accuracy/bad leveling: 53%

- Entrapment: 16%

- No protective devices on power-operated doors: 16%

- Lack of car doors: 4%

- Locking problems: 4%

- Uncontrolled movement of car: 4%

- No safety gear or overspeed governor on electric lifts: 3%

Rivet revealed the report has recorded 2,404 user accidents between 2008 and 2011. He then turned attention to the aforementioned Amendment A3 to the European code. This was an important presentation for Polish lift professionals, as it showed what the more-established EU and ELA members have achieved and the initiatives they are implementing.

The next presentation was given by Imro Garcia of Eurlicon, a lift consultancy based in Amsterdam. This important presentation took the client’s point of view, in which Garcia highlighted the real costs of service and maintenance, which are always in the forefront of a lift owner’s mind. Garcia stated that trust is all important when dealing with clients:

“Where once reliance was placed on the experience and knowledge of maintenance companies, owners now rely on clear rules and requirements, where performance is measured and monitored. It appears that maintenance companies find it difficult to meet all commitments and that the performance delivered does not match the expectations of the customer. In this regard, the business interests of the maintenance companies are often opposed to the interests of the customer.”

The delegates were then treated to a presentation by Leszek Fidelus and Rafal Firganek of UDT. This fascinating look at the historic lifts of Poland explained how to adapt them without destroying the integral value of the system and craftsmanship employed in manufacturing them. We were informed that there could be more than 25,000 installations in Poland that fall under the new category of “historic lifts.” Most are more than 60 years old and have had no modernization. Most international lift specialists at the conference were encouraged that many Polish technicians had hands-on experience of the old installations and were actively adapting components, re-manufacturing products long out of production and finding new ways to allow these installations to remain safely in service.

Dominik Bartecki of TÜV SÜD then presented on the ADIASYSTEM with a number of computer supported tests and measurement activities related to the safety functions of lifts, as well as operating performance and ride quality. Bartecki explained the lift measurement range of the ADIASYSTEM solution exceeded traditional measurement methods, allowing for the precise recording of technical parameters.

Cezary Woch and Mikolaj Sochacki of Lift ER walked delegates through a way of organizing a number of network operations. In the world of lifts and escalators, code requirements, design and maintenance needs, technicians and service support can all be optimized with system security support using cloud networking, as is the Lift ER platform, which allows access to advanced systems in the form of software as a service. This solution relieves the entrepreneur from the need of maintaining an information-technology department.

Day Two

Popielas welcomed the delegates to the second day of the conference and explained that many presentations taking place during day two were connected to the implementation of pnEN 81-1 and -2 Annex A3 and the work currently underway on EN 81-20 and -50. Due to numerous changes and new elements being added to the old codes, PALM felt it important that delegates spread the word so everyone working in the field could get up to date on the directives and norms. Popielas stated it was a pleasure to have such a good panel of specialists to present this material to the conference.

To start the main presentations, Willem Kasteleijn from Liftinstituut gave an informed look at the practical experience of UMC (A3) protection in certification and final inspection. Kasteleijn looked at EN 81-1:1998 +A3:2009, with particular focus on the A3 safety elements, such as the fixing elements of removable guards and uncontrolled car movement protection.

The next presentation was given by Pawel Rejewski from UDT. Primarily for the Polish companies, Rejewski explained the revisions underway to the Lifts Directive. This presentation was in Polish, so all the implications could be understood without the interruption of translations.

Lech Zdunek and Lars Kollmorgen gave a joint presentation on lift controls as related to Annex A3 as it is in practice. The control products MPK 300 C and MPK 800 with the FPK processor and the UCM SM A3-005 were shown as examples during the presentation, which showed how lift-control products are influenced by the various requirements contained in EU codes and standards.

Wolfgang Adldinger from Wittur spoke on the topic of codes and norms for lift design. Adldinger is convener for the components committee and working group, and has many years of experience in codes and standards. He investigated directives, norms and design solutions, including solutions for Russia. Adldinger closed his presentation with a look toward the future and discussion on what would be joining the complicated mix that makes up the ever-growing collection of European directives and norms.

Stephan Stoermer from TÜV Austria presented an overview of EN 81-20 and -50, and discussed their future effects in the design and planning of new lifts. Global acceptance and application of EN 81 was also examined, along with links to other national and international standards. Several technical changes were discussed, as were new considerations involving static forces and energy.

In closing, Popielas thanked the presenters and delegates for their attention and support. He hoped all the officers and representatives of the different companies and organizations present would pass on what they gained from the congress, so the implementation of all the codes and standards would be simplified.

Get more of Elevator World. Sign up for our free e-newsletter.