Grand Central Madison Sidewalk Lift

Mar 1, 2025

Gillespie Corp. details the story behind its recent challenging NYC sidewalk lift project.

by John C. Linsley

Not far from Grand Central Station in NYC in a drive through bay is a large sidewalk lift designed and built by Gillespie Corp. The story of this lift began in 2009, 13 years before it was installed in late 2022 and the early spring of 2023.

Located approximately 140 ft below Grand Central Station is a new terminus for the Long Island Railroad (LIRR). Here, eight train tracks located in two tunnels bring trains from Long Island into the Midtown East neighborhood of Manhattan. Instead of traveling to Penn station, commuters now have the option of using Grand Central Terminal. Gillespie was contacted by representatives of the NYC Metropolitan Transit Authority (MTA) to design a large sidewalk elevator capable of carrying a full-size garbage truck to service the trains arriving at the station. This was later scaled down in both size and purpose, and we were again contacted several years later by Schindler Elevator.

At this point, the elevator was now designated a lift or vertical reciprocating conveyor (VRC) under ASME B20.1-2018 Safety Standard for Conveyors and Related Equipment, per the MTA’s request, though it was designed and manufactured under A17.1 Safety Code for Elevators and Escalators.

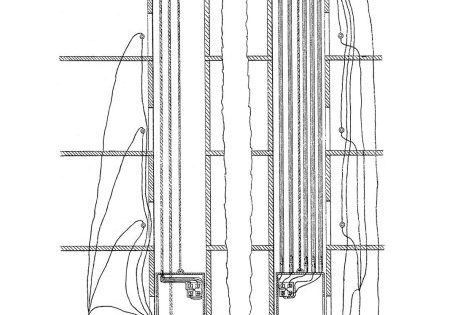

Though only having two stops, it travels just over 53 ft from the lower landing to the upper landing. The lift was now designed with an 8 ft and 4 in. wide by 16 ft and 11 in. platform, a capacity of 20,000 lb, Class C2 loading, with a single inground cylinder provided by ITI Hydraulik. The power unit is a dry unit with a 75-hp motor. Class C2 loading must be designed for the rated capacity plus an additional 50% of the capacity while loading and unloading. It is not necessary to move this additional load, but the design must be able to support it. All told, including the empty car weight, 20,000 lb capacity, 10,000 lb for C2 loading and the vertically lifting deck door with a weight of 14,500 lb. The total load added up to 62,000 lb during loading.

During travel, the load was a maximum of 52,000 lb, not including the weight of the piston. The piston of the in-ground cylinder is 13-3/4 in. in diameter, with a .813-in. wall thickness, and weighs an impressive 6790 lb. With the 18-in. casing weighing 8030 lb, the total assembled cylinder weighs 14,820 lb, not including the 24-in. diameter PVC liner. The cylinder was built in three sections, with the casing being both threaded and welded.

The lower landing is pass through, with powered freight bi-parting doors and powered car gates, front and rear, supplied by Courion. The car gates are powered, single section slide down in design, which is unusual. Gillespie has made use of slide down car gates built by Courion on several previous occasions. The car side walls are 7 ft and 6 in. tall, made of bent 14 ga. 2-in. deep panels finished on the interior with 1/8 in. aluminum diamond plate. As with most sidewalk elevators and lifts, no canopy is present. A NEMA 4X car station from Innovation Industries was provided to allow for operating the gates and doors while on the car. Because this is a VRC there are no floor buttons present on the car.

The primary challenge associated with this elevator was the vertically lifting deck door.

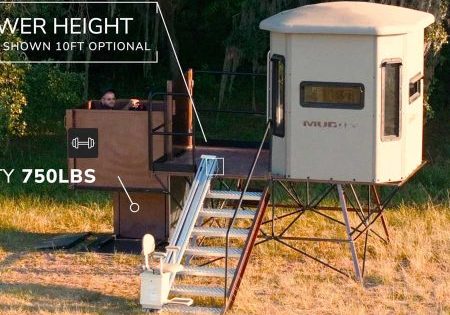

A vertical lifting deck door is a single piece door that is picked up by stantions on the car as the car rises to grade. This design is structurally stronger than a standard two-piece hinged door. The vertical door is particularly suited for heavy duty, AASHTO H-20 and H-25 rated deck doors as described below. The American Association of State Highway and Transportation Officials (AASHTO) is a standards-setting body that publishes specifications, test protocols and guidelines that are used in highway design and construction throughout the U.S.

All operation takes place from a single location: the sidewalk station placed at the upper landing within visual sight of the deck door. This station controls operation to and from the lower and upper landings, as well as car gate operation. The lower pass-through landings have door and gate operation buttons, as well, but no call or send buttons.

The elevator itself was not a particularly difficult design. Gillespie has built much larger cars of this type. The primary challenge associated with this elevator was the vertically lifting deck door. This door is rated for AASHTO H-25 truck loading, which is a 40,000 lb live axle load. Gillespie has designed and built many heavy-duty AASHTO H-20 and H-25 sidewalk doors in the past, but this was the largest, at a weight of 14,500 lb.

The design requires six stanchions mounted on the underside of the deck door, to be engaged by six similar but larger tube stanchions built as part of the car frame. As the elevator travels upwards, it engages the deck door stanchions, which eventually set down onto heavy-duty springs contained within the car stanchions. The deck door is then picked up by the elevator itself and rises 13 ft and 4 in. above the deck floor when the car is level with the floor. Traveling in the down direction, the deck door is set down into a gutter frame embedded into the deck. This deck door frame is designed to gather what water gets past the door plate with the water being piped to a sump pump in the pit below. The elevator, after setting the deck door onto the frame, continues traveling downwards, eventually disengaging from the deck door stanchions and reaching the lower landing.

The Gillespie Team, Schindler and our suppliers worked together to produce a large and unusual sidewalk lift that will be used for decades to come.

The Grand Central Madison project was designed and manufactured by Gillespie Corp. in Ware, Massachusetts. The project team includes Gillespie Operations Manager Greg Thompson; Engineering Manager John C. Linsley; Senior Engineer Yakov Mikhlin; and Gillespie’s fabricating team Pawel Bzdula, Roger Jerome, Leszek Lebida and Steve Salerno. Worcester County Welding, Corp., in Leicester, Massachusetts, acted as the car fabricator. Professional engineers Christine H. Roy, P.E. (MA) and Simpson Gumpertz & Heger also worked on the project. Schindler Elevator Corporation acted as installer, while Virginia Controls, LLC, manufactured the controller; ITI Hydraulik manufactured the hydraulics, and Innovation Industries Inc. manufactured the fixtures.

Get more of Elevator World. Sign up for our free e-newsletter.