“Into the Hydraulic Elevator World”

Dec 5, 2020

Contractor and component maker tout the advantages of non-traction alternative.

submitted by Omarlift

Hydraulic elevators have inherent advantages, and two companies — CEDAS and Omarlift — organized an event on September 7 designed to get the word out. “Into the Hydraulic Elevator World” took place in the Diamond Room at Novotel Dubai. Based in Ajman, U.A.E., CEDAS is a growing provider of vertical and inclined building-transportation and accessibility solutions. Omarlift, of Bagnatica, Italy, is its supplier of hydraulic elevator components.

Introducing the event was Zain Ahmad, sales and marketing manager for CEDAS, joined by Omarlift executives Alessandro Mordini, CEO and sales director; Massimiliano Calcerano, marketing manager; and Giulia Azzimonti, marketing and communication specialist. The group discussed their views on the efficiency of hydraulic installations in detail.

Though Middle East architecture is known for the dizzying heights common to many of its landmark buildings, hydraulic elevators remain widely popular in the region. The presenters noted that, because they are easy to maintain and offer reduced installation time, hydraulic elevators are a cost-effective solution for residential and commercial buildings, as well as for marine installations, because these applications typically see moderate travel and fewer floors, and work well in limited space.

These features provide a particular advantage for the home lift. Since it is not necessary to have a machine room, the pump unit and control panel can be mounted in a dedicated cabinet and placed in a convenient location in the building — not necessarily at the top of the elevator shaft or even immediately adjacent to it. The lack of a counterweight makes it possible to place these components directly in the pit or shaft.

Moreover, hydraulic lifts present an even clearer advantage in the context of buildings that need practical solutions to overcome architectural barriers that present problems for older people or others with problems of reduced mobility that can impact their independence.

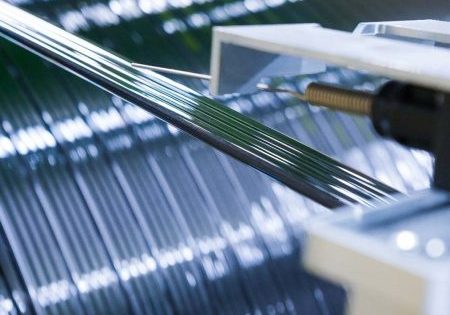

High-quality, reliable components are indispensable when it comes to safety, and, in general, hydraulic elevators can provide the highest level of protection thanks to specific, European Union-certified components, such as a pipe rupture valve on the cylinder and the unintended car movement (UCM) redundant

valve, an optional device placed on the pump unit that controls the oil flow. These are, respectively, a safety device against freefall of the cabin (in cases of significant leakage in the hydraulic circuit) and a safety component (in combination with the controller) against UCM with open doors.

Furthermore, in the case of power outages in which passengers are stuck in the car, it is always possible to move the cabin to the floor manually, thanks to the hand pump or an emergency lowering button (also available for automated battery operation).

The day ended with an exchange of views on how to improve the performance of standard hydraulic elevators, and an analysis of customer case studies to clarify doubts and offer suggestions.

Get more of Elevator World. Sign up for our free e-newsletter.