It Is Safety Awareness That Counts!

Nov 1, 2015

In this Readers Platform, Elevator World’s Chinese correspondent explores the safety concerns around accidents in China.

By 2014, there were more than three million elevators and escalators in China. This number will continue to grow alongside the accelerating urbanization of the country. People, especially those living in cities, are entering an age of vertical transportation.

On July 26, a 30-year-old woman rode up an escalator with her three-year-old son between the sixth and seventh floors at a mall in Jingzhou, China. When she set foot on the escalator’s horizontal cover plate at the upper landing, the plate flipped up, and she and her son fell into the truss, where the escalator’s machine and transmission mechanism are housed. She immediately pushed her child up and out to safety. Moments later, she completely disappeared into the escalator truss.

When two or more adverse factors come into play at the same time, it usually results in an accident.

The accident caused widespread public concern about escalator safety, while the investigation – the most responsive and fastest ever in Chinese history – uncovered the causes of the accident as the result of human error on multiple levels. There is widespread sympathy for the young victim and her family, and the sincere hope similar tragedies will never happen again. The liable parties not only have to compensate the victim’s family, but they will also face great losses in business and reputation in the years to come – especially the manufacturer, because Hubei Province has announced it is banning the company from making future installations. The General Administration of Quality Supervision, Inspection and Quarantine of China issued an emergency notice to its subordinate authorities at various levels to examine currently operating escalators unit by unit.

According to the results of the investigation, the manufacturer and mall management are primarily responsible, and the maintenance company is partly responsible for the accident due to incomplete records. The four major causes of the accident have been identified as follows:

- Direct cause: the first cover plate next to the leveling step was unfastened.

- The escalators were NOT switched off in time after the hazards had been reported five minutes before the accident occurred.

- Defective design made the three cover plates prone to getting loose and turning over. The size of the plates was NOT in conformity with those specified in the drawing – they were too small for the landing area.

- Unregulated maintenance led to incomplete maintenance records. Maintenance procedures should meet the requirements as set forth in the national Production Safety and Special Equipment Safety laws.

How Do Accidents Happen?

When two or more adverse factors come into play at the same time, it usually results in an accident. Not long ago, a man assaulted a doctor who treated a family member of his. The man dragged the doctor into the elevator lobby and slammed him hard against an elevator’s landing door. Unfortunately, the door was not strong enough to withstand the force, and, as a result, both persons fell down the shaft and died. Two factors contributed to this accident: excessive force and a weak landing door.

History sometimes repeats a lesson to those who fail to learn from it. Another escalator accident that caused public outcry took place in July 2011 in Beijing. It was answered in a similar way by various parties. According to the investigation into that accident, a broken bolt was responsible for the inverting movement of the steps, and both brakes failed to stop the inversion. Two factors contributed to this accident: a broken bolt and brake failure. The product design was declared defective, and the manufacturer was banned from making installations in Beijing, while the top authorities issued an emergency notice for its subordinate authorities to examine currently operating escalators unit by unit.

Unfortunately, the routine measures taken by the authorities have proven ineffective in preventing similar escalator accidents. In July’s accident, there seem to be more than two contributing factors. After analyzing the facts, the conclusion drawn is that the tragedy could have been easily avoided.

Safety Awareness Is Lacking

A number of people could have helped. The mall manager, who received the hazard report, should have taken immediate action to stop the escalator. Unfortunately, he failed to do the right thing in time. More than one mall clerk was standing at both the lower and upper entrances of the escalator, but they did nothing until they saw the victim fall into the escalator truss. If any one of the four ladies standing by had had the wherewithal to step forward and press the emergency-stop button, the woman could have been saved. Nobody at the scene of the accident had the slightest notion of safety awareness, and nobody, except the person who had reported the malfunction of the cover plate, did the right thing.

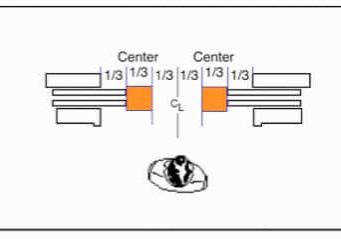

The designers made a primary mistake in the cover-plate arrangement. The design principle calls for plates to stay put, even if they are not secured by screws or bolts. It seems they do not know how escalator cover plates should be protected in the event one of them maneuvers out of place. They apparently had too little safety awareness to be designers.

Raising and Measuring Safety Awareness through Inspection

The annual inspection cannot guarantee passenger safety. It is safety awareness that counts! The equipment-inspection system needs to be updated, because it makes no sense to say the unit was found to be in good condition during annual inspection but caused an accident two months later. The inspection authorities should NOT just check the equipment, put on a label with an expiration date, collect their pay and walk away. The safety awareness of the owners, managers, supervisors, staff and workers in the building should be measured and scored in the inspection process. If everyone in the building has sufficient common sense regarding elevator and escalator safety – for example, knowing the location and function of the emergency-stop button – accidents can be substantially reduced. One day in early August, shortly after the accident in Jingzhou, an elderly passenger stumbled on an escalator at a metro station in Shenyang. Another passenger pressed the emergency-stop button and prevented the passengers riding the same escalator from getting injured.

There have been safety laws that included the training of personnel. Why not make employee safety-awareness training a hard and fast rule to be enforced by certified inspectors? This would be more effective than giving orders to have each elevator and escalator examined after a major accident.

Most manufacturers have their own safety-awareness programs for users. They could play a valuable role if asked to work with the safety-supervision authorities on the nationwide safety-awareness program for building owners and their employees.

Proposals

The designer’s safety awareness is essential for products. One should give top priority to guaranteeing passenger safety in every detail. They must consider whether it is strong enough. Safety must be made sure and firm. It cannot be based on a number of screws and/or tension pins. These small pieces are vulnerable to getting lost on the jobsite or overlooked in work. Is it protected in the event that one part fails or gets broken? Is it maintenance friendly? Making things easy in maintenance is also important, as field technicians sometimes tend to overlook something. For example, they may forget to remove a jumper from the door safety after work. A good designer ought to think from the perspective of the field technician. If a support beam has to be removed for work, it must be put back in place before the technician leaves. If such a component is missing, the system should refuse to work by design.

The supervisory authorities could work out detailed rules to integrate building owners’ responsibilities with laws and regulations to further the nation’s laws on safety. The building owners’ level of safety awareness can be made measurable and, thus, operational in practice. This could be specified in requirements, and recorded and scored during the annual inspection to motivate building owners to train themselves and their employees in safety awareness at the appropriate level for each type of employee.

There are three levels of safety awareness that correspond to different employees.

Level One: Engineers

Level One is for onsite engineers or field veterans who usually hold a field-operation license for special equipment or have worked as inspectors or field engineers. They are specialists. A building owner must hire one or more engineers depending on the number of units in the building. They shall supervise the maintenance contractor and report equipment conditions to the owner in a timely fashion and handle emergency events. They are responsible for taking immediate measures toward passenger safety, such as releasing entrapped passengers from the car or closing entrances to a broken down unit. The owner can also contract such a service from a manufacturer or specialized service provider.

Level Two: Managers

Level Two is for managers, supervisors, electricians and group leaders working in the building. They are not elevator specialists but are to have sufficient knowledge concerning the structure, operational theory, major components and their functions on elevators and escalators, so they know what to do in the event of an emergency. They shall help supervise the working conditions of the equipment on a daily basis, and report the hazards they see to their manager or to one of the onsite engineers immediately. They are also able to talk to the entrapped passengers to calm them and tell them what to do and what NOT to do.

Level Three: Personnel

Level Three is for all the others working in the building. They are supposed to have common sense regarding elevator and escalator safety and how to be a safe rider. In addition, they shall be trained how to report to their supervisor or manager upon seeing any equipment issues and know how to use the emergency buttons.

To be a safe rider takes work for both adults and kids who use elevators and escalators every day.

To Be a Safe Rider

To be a safe rider takes work for both adults and kids who use elevators and escalators every day. A number of leading manufacturers have been doing this for years with positive effects. Industry media such as China Elevator issue pamphlets about passenger safety from time to time. However, these efforts made by the industry itself still seem to be a drop in a vast ocean compared with the country’s massive population and widespread installations.

Here are some common-sense rules with regards to escalators and elevators. Ladies in skirts or heels should keep off the yellow lines on the step, and mothers should keep a close eye on their children so that they do not stick their fingers or shoes into the moving sides. In the event of being trapped in an elevator, passengers should NOT try to open the door by force to escape, but stay calm and call for help. They should be aware of the fact that standing in the door-opening area is the most dangerous thing to do, because, by doing so, they expose themselves to the risk of being sheared by the moving car. Also, passengers should never try to open a landing door from outside by force or with an unauthorized key while the elevator is not there. By doing so, they will be at the highest risk of falling into the shaft.

The present situation is, sadly, that nine out of 10 passengers are illiterate with regards to riders’ safety. If the safety supervisory authorities take riders’ safety issues into consideration and work out guidelines and effective measures to raise the safety awareness of the public, the prospect would look bright and injury and death rates relating to vertical-transportation equipment would be substantially reduced.

China has a well-developed elevator industry and healthy public media system to help implement this program once it is made available. Media such as newspapers and television programs could carry public-service advertisements regarding riders’ safety. Posters and pamphlets on how to be a safe rider could be used at metro stations for citizens.

Get more of Elevator World. Sign up for our free e-newsletter.