Maintaining Elevators and Escalators in the Transit Environment, Part 1

Dec 1, 2012

An overview of the equipment and standards of escalators and elevators in transit systems

Mass transit found in many major metropolitan cities is an intermodal network connecting bus, rail, automobile and air modes. These modes can be in subway, elevated and at-grade forms. This transportation is critical for daily commuting, and intercity and international travel. These systems started in the mid 1800s in New York City and Boston, spreading throughout the Northeast to Philadelphia and west to Chicago. Later, in the mid to late 1900s, systems were built in Washington, D.C., Atlanta, Los Angeles and San Francisco. Now, they can also be found in other cities, such as Dallas, Seattle, Baltimore and Miami.

Learning Objectives

After reading this article, you should have learned:

♦ The equipment used in U.S. transit systems is subjected to far greater usage than any equipment found in any of the busiest high-rise office buildings and even most shopping malls on the busiest holiday shopping period.

♦ The standard escalator has its motor and brake at the top of the machine, while the modular escalator has a number of modules extending along the incline, depending upon the rise of the escalator.

♦ Having different vertical-transportation equipment suppliers can foster competition, but there are downsides to this practice.

♦ Why many transit agencies defer replacement or major repair of elevators and escalators

♦ How exposure, usage and loading differ between transit systems and commercial/office/retail buildings

These systems are a combination of heavy- and light-rail trains, as well as bus and para-transit equipment. Trains and buses are often thought to be their most critical and important pieces of equipment. This is true to an extent, but the often-neglected elevator and/or escalator takes the patron from the entry level of a system to its track or bus-bay levels to gain access to those buses and trains. Then, the same equipment often transports the traveler to the desired floor at his or her destination. Some of it sees in excess of 8,000 riders per day. Not counted in this figure are the many pieces of internal and construction equipment elevators are often used to transport.

Equipment Type and Design

The elevators and escalators found in transit systems are subjected to far greater usage than any equipment found in any of the busiest high-rise office buildings and even most shopping malls on the busiest holiday shopping period. In addition to this high usage, these units are subjected to strong environmental and non-environmental conditions rarely seen in commercial applications. Most major escalator manufacturers, both current and no longer in business, are represented in these systems. Elevators produced by these manufacturers, as well as a longer list of medium-sized and small elevator manufacturers, are also present.

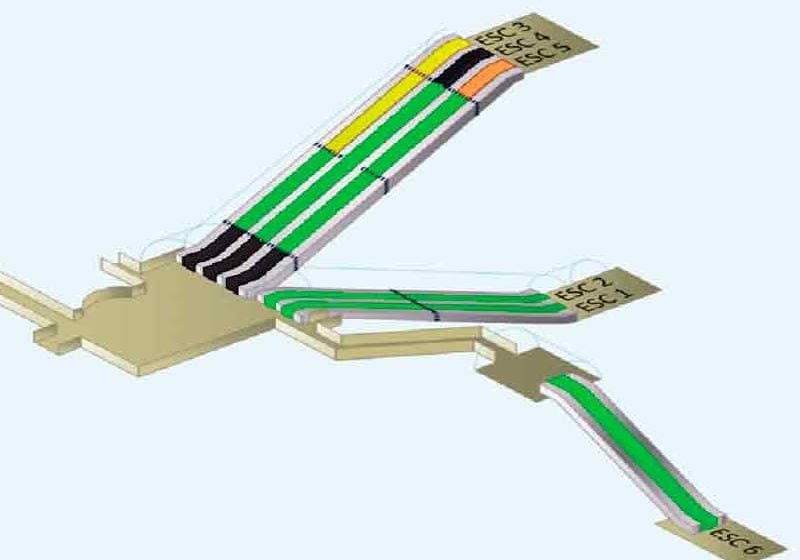

The Westinghouse Modular 100 escalator is one of the most prominent in many large transit systems in the U.S. For example, there are 121 of these in the Metropolitan Atlanta Rapid Transit Authority system (MARTA) in Atlanta, making up more than 81% of its 149 escalators. Approximately 50% of the escalators in the Bay Area Rapid Transit system (BART) are Westinghouse, and the Washington Metropolitan Area Transit Authority (WMATA) has 430 (73%) Westinghouse Modular 100 units in its system, with more in the New York City Transit and Chicago Transit Authority systems. Most of these were installed in the early 1970s through the mid to late 1980s.

Ann Scott Tyson of the Washington Post, quoting an industry consultant indicating widespread dissatisfaction with the performance of the Westinghouse escalator, pointed out:

“The Washington Metro may be the world’s largest owner of an outmoded and problematic type of escalator, one that has had brake-failure accidents in other transit systems and is known among experts for requiring a high level of maintenance.”

It is true that the Westinghouse Modular can be problematic and is maintenance intensive; however, we must also remember that it was the best-engineered and most cost-effective solution for the needs of many systems at the time (early 1970s-1980s). No standard escalator design could meet the requirement for a single escalator to span rises in excess of 65 ft. This is still a limitation with most escalators today. The unique design aspect of the modular escalator made the Westinghouse model well suited for the transit environment. Some escalators in service span well over that 65-ft. mark, such as the unit in the CNN Center in Atlanta, but the escalators that are used in the transit environment must be designed to much more stringent guidelines due to the loading, usage and environmental elements to which they are subjected during revenue hours, which, in many cases, is 20-plus hours per day, seven days a week.

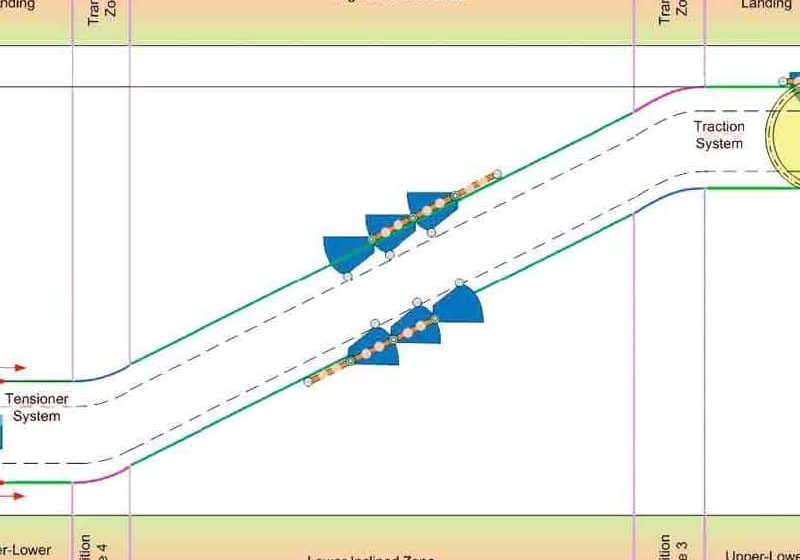

As its name indicates, the Westinghouse Modular has a unique design. The standard escalator has its motor and brake at the top of the machine, while the Modular has a number of modules extending along the incline, depending on the height rise of the equipment, each module containing a separate motor and brake. Escalators with a single module are used for short applications found mostly at the interior mezzanine and track levels, while the deeper station entrances or elevated platforms typically have between two and five modules, and sometimes more. The Modular also uses a unique step-driving system comprised of a drive chain on each side of the escalator with axles spanning between the chains. This design is more commonly referred to as a rack-and-axle system, or simply “the rack.”

Each module, including its corresponding motors and brakes, must be adjusted to share the load across all modules to reduce uneven wear of the motors, brakes and rack. This adjustment process is commonly referred to in the industry as “load sharing.” Proper load sharing of the Westinghouse Modular is one of the most critical maintenance issues with that design. I would venture to say that few systems or the service companies that maintain them have employed a mechanic proficient in performing a proper load-share adjustment on Westinghouse escalators with three or more drives.

In addition to the Westinghouse units, many systems have older O&K, Montgomery and APV escalators, each of which has its own set of unique design characteristics and maintenance issues. In addition to the unique maintenance requirements of this different equipment, another factor that comes into play is that none of these four companies is still in business.

In 1989, Westinghouse was purchased by Schindler of Switzerland. Schindler continued to manufacture and install the Westinghouse escalator and its Modular 250 variant through the 1990s in WMATA. KONE of Finland acquired Montgomery, APV and O&K in 1994, 1995 and 1996, respectively. The sheer number of Westinghouse escalators in use has kept their parts’ availability rather strong, and they are still manufactured and stocked by both Schindler’s parts group and other industry-equipment suppliers.

Still, maintenance for older elevators and escalators is very labor intensive, and, unfortunately, the pool of technicians with experience maintaining those units is being lost as the older mechanics are retiring from or otherwise leaving the industry. In addition to these labor issues, parts support for the other three manufacturers has a rapidly dwindling availability throughout the world, and it can take upward of six months to have parts manufactured, if they can be replicated at all. One of the main reasons is that there are relatively few in our systems, and manufacturing special parts on such a small scale is very expensive, if not cost prohibitive. This fact has caused many systems like WMATA and MARTA to begin planning for the replacement of all their O&K and APV escalators.

On the elevator front, Schindler also purchased Haughton Elevator. US Elevator and Dover Elevator were purchased by ThyssenKrupp Elevator of Germany, and Armor Elevator was purchased by KONE. These acquisitions, coupled with dwindling parts support and the lack of qualified service technicians, make the maintenance of existing elevators from these retired brands increasingly difficult.

Factors Affecting Equipment Condition

In addition to the design- and parts-related issues that can affect technicians’ ability to properly maintain escalators, there are other external issues that can steadily erode years from equipments’ useful life. Elevators and escalators are complex systems of electromagnetic sensors and controls with many moving parts and important safety devices. Like all machines, elevators and escalators need periodic lubrication and adjustment to ensure their components remain in proper working condition. To provide the lifespan expected at the time the equipment was installed, transit agencies must ensure an adequate maintenance program is in place to care for it. This process is the only way a constant state of good repair can be maintained.

Whether the equipment is maintained by an outside service provider or by in-house maintenance (what many transit authorities have moved toward), the equipment must be serviced and adjusted to maintain proper operating conditions as outlined by the OEM and all applicable governing codes. In order to have a successful maintenance program, all technicians working on the equipment must have proper training and access to the necessary equipment parts. Vertical-transportation equipment maintenance can be equated to the maintenance of its rolling stock (i.e., trains and buses)

Although it can be desirable to have more than one equipment supplier to maintain good competition and ensure equipment availability, having many different equipment manufacturers can present problems both in stocking adequate supplies of parts and training mechanics on the numerous pieces of equipment, wherein they will have to learn the intricacies of adjustment and service for each. A survey prepared by the Elevator and Escalator Technical Forum of the American Public Transportation Association found that of the transit authorities that responded, the average authority had over five different escalator manufacturers and 10 different elevator manufacturers in service in its system.

Educating and retaining maintenance personnel, along with a sufficient parts inventory to ensure proper operation of a diverse mixture of equipment (as indicated above), can be extremely difficult and costly, whether done by an in-house maintenance group with its own training or if the maintenance services are contracted to an outside service contractor. However, a sufficient number of mechanics with training on all of the equipment to be maintained and financial stability are musts.

When installed correctly, new elevators and escalators can often operate for months with minimal attention or adjustment. Far too many times, new installations have been neglected, while more attention is given to a more problematic area, only to find that neglect has resulted in problems both costly and out of the normal realm of regular maintenance and routine repair.

Another unfortunate event that can have an adverse effect on the equipment occurs when a good maintenance program is in place and the equipment is running well. Maintaining strong operating and capital budgets are a significant issue, especially in today’s economic climate. Finding ways to stretch those budgets is critical. It is common to defer major upgrade or replacement of capital equipment and allocate funds to what appears to be a higher-priority area. However, just because those elevators and escalators have been maintained properly and operating well over an extended period does not mean the lifecycle can be extended 50-75% past what was originally expected. An elevator or escalator operating in the transit environment, when properly maintained, should have a useful life of 20-25 years. Much of the vertical-transportation equipment operating in our transit authorities is well over 40 years old, with minimal upgrade or major component replacement.

Transit systems are unique transportation networks and subjected to environmental and operational conditions that few other types of commercial equipment is routinely subjected to. Most transit stations are located outside, with a few subterranean stations located below a downtown financial district or the occasional deep station in the suburbs (due to terrain or elevation of the rail network). Even those stations likely have entrance-level equipment exposed to the elements. Harsh climate conditions and even normal rain, snow and temperature extremes have major negative effects on the operation of elevators and escalators. Metal and electronics are susceptible to weather, and hydraulic elevators are particularly sensitive to temperature extremes unless climate control has been designed into the machine-room environment. Temperature extremes also affect most microprocessor control systems.

Damage from vandalism and natural disasters reduce the life expectancy of vertical-transportation equipment, and its performance and availability to the patron. Equipment in transit systems is damaged when elevators are used as public restrooms or escalators are used as ski ramps. They can also feel the brunt of many people’s frustrations and disdain for public property when escalator handrails are sliced, stainless-steel panels are beaten and elevator car-operating panels (COPs) are defaced or damaged. Any authority fortunate enough to have closed-circuit monitoring within its system has witnessed many cases of this sort of misuse and abuse on its equipment. Even though an owner may have full indemnification to its service provider, most U.S. states have a form of premises liability that indicates the owner (in this case, the transit authority) has a non-delegable duty to provide safe equipment for all users.

Transit equipment is also subjected to routine overloading by both internal staff, as well crowds during special events that occur in and around their stations. Most class-A office facilities have a service elevator to handle the transfer of large and heavy equipment, and most people wait for the next elevator, instead of forcing themselves into an already-crowded cab. Unfortunately, this is often not the case in the transit environment. Whether systems have service or freight elevators at each of their stations, it is common practice to collect and move fare gate receipts through the system using the standard station elevator. Even elevators designed for combined passenger and freight use are not capable of carrying the equipment they are routinely asked to transport. Capacity should be clearly identified on the COP, and all maintenance staff should know the weight and size of the equipment to be moved. This capacity should not be exceeded, even if it is the most convenient way to get it to or from the platform.

Equipment used in commercial facilities – even the busiest mall during the holiday shopping season – would rarely be subjected to the loading units around many special events nearby transit stations experience. One only has to watch the WMATA Smithsonian or Arlington stations during U.S. Independence Day celebrations or the Five Points, Georgia Dome and Vine City stations at MARTA during the New Year’s Eve Peach Drop to see that the escalators are routinely stacked with patrons anxious to enter and exit with little knowledge of the potential to overload the equipment. Part six of ASME A17.1 has equations used for calculating rated loads for escalators, and that rated load is specific for each escalator based on its height rise and equipment configuration. Far too many incidents of improperly maintained or maladjusted brakes have occurred, but it is also possible to overload an escalator that has a properly maintained and calibrated braking system. You only have to look at numerous videos on YouTube to see what will happen when too many people attempt to crowd onto the escalator at the same time. Proper crowd control must be in place in order to prevent overloading during these instances. Contrary to what may be thought, no elevator or escalator is designed to handle the number of people or all of the things that can be forced onto them at any given time.

Could equipment be designed to withstand the exposure and loading that have been mentioned? Clearly, the answer is yes; however, few transit authorities would be willing to pay the costs this equipment would demand. Keeping in mind that fare revenue is only a small part of most transit agencies’ operating budgets, adjustments and concessions must be made, especially in the current financial situation. The status quo cannot be maintained, regardless of how much individuals or special interest groups may protest; something must give in order for public transportation to continue to operate.

At a time when operating budgets are feeling the pinch of the troubled economy, transit general managers and boards of directors are faced with difficult decisions to balance their budgets. Staffs, both in management and the union workforce, have been reduced; salaries and wages have been frozen; unpaid furloughs have been mandated; and cuts in service have been necessary. These actions, however difficult, have met with anger and protest, but the situations called for drastic measures, and tough decisions were made. Along with these short-term fiscal decisions, long-term fiscal and operating policies must be changed, as well. In Part 2 of this article, we will see how the situation in the transit environment got this way and what can be done to get out of it.

Learning-Reinforcement Questions

Use the below learning-reinforcement questions to study for the Continuing Education Assessment Exam available online at www.elevatorbooks.com or on page 125 of this issue.

♦ Was the Westinghouse Modular escalator a good engineering solution for transit systems in the 1970s and 1980s?

♦ What differentiates the modular from the conventional escalator?

♦ What are some factors that affect equipment in transit systems that are rarely found in equipment installed in the commercial environment?

♦ How have declining budgets and early equipment performance affected replacement in our transit systems?

♦ Can an escalator’s rated loads be exceeded by the loading of passengers? Why?

Get more of Elevator World. Sign up for our free e-newsletter.