Mongrain Vertical Transport (MVT) is an international builder of hydraulic elevator packages, featuring its Leistritz Emarelle™ machine-room-less (MRL) hydraulic elevator (ELEVATOR WORLD, April 2013). However, while that counterweight roped system is intended for four-to-10-floor applications, MVT has since developed a new low-rise, direct-acting hydraulic elevator package for the two-to-three-floor market segment, dubbed the “Low Rise Emarelle.” Intended to be more cost efficient, the new system has the same benefits but at a lower total installed cost than the counterweighted product. The new elevator is based on a lightweight, twin-post concept with various enhancements.

Power-Unit Design

MVT touts its new vertically installed, air-cooled motor as having greater efficiency than equivalent submersible motors. It thus requires less cooling, thereby protecting equipment and oil from heat degradation. As the motor is not submerged in the oil, possible motor failure will not contaminate the oil.

The MVT dry power unit is rated for a 280-gpm oil flow, 750-psi working pressure, 75-hp motor size and 120 starts per hr.

This LTPA dry power unit uses a vertical pump enclosed in the tank, eliminating potential leaks into the environment. A simple direct drive (with no shaft seals, sheaves or belts) is intended to reduce maintenance costs. The power unit is also designed to give the advantage of eliminating vibrations and noise from belts and sheaves. Additional features include isolation pads for motors, a low-noise screw pump and a flexible feed line between the pump and the valve to further reduce the already low pump pulsations.

Hydraulic-Control Technology

The Low Rise Emarelle is intended for use in both new and existing elevator installations. According to MVT, the use of its closed-loop electronic valve with continuous pressure/viscosity compensation brings several advantages over a classic mechanical valve, such as constant ride quality, lower power consumption (due to shorter travel time), easy setup and no required seasonal adjustments.

MRL Concept

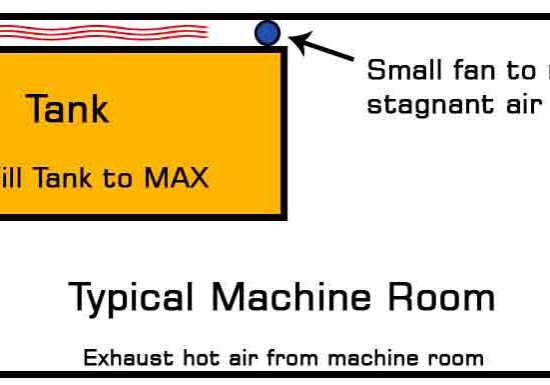

The MRL concept of the system is intended to be an advantage for limited spaces. The power unit with its accessories measures 3 ft. wide, 1.5 ft. deep and 2.5 ft. high and is enclosed behind fire-rated doors in a space adjacent to the hoistway, which ensures easy and safe access to the equipment from outside the hoistway. Power and control components are also placed near the power unit in the same space. Heat generated by the various components is transferred into the hoistway by convection, where it can dissipate outside by natural airflow. Thus, there is no need to supply air-conditioning or forced air ventilation. In addition, the space-saving design enables architects and consultants to save on building materials, labor and energy.

For more information, contact MVT at e-mail: [email protected] or website: www.mvtinc.com. Submitted by Sylvain Mongrain, Jean Larcher and Nicolas Bluteau.

Canola-Based Hydraulic Fluid

ThyssenKrupp Elevator has partnered with BioBlend Renewable Resources LLC to develop an alternative to petroleum–based fluid. The product created, enviromax, is formulated from canola oil and exceeds the highest standards for biodegradability. It takes only a year to regenerate, instead of the tens of thousands of years required for the regeneration of petroleum-based fluid. With 92% bio-based content, enviromax is bio-preferred by the U.S. Department of Agriculture and allows hydraulic elevators to run on rapidly renewable, readily biodegradable fluid with minimal effects on the environment. It is 95% petroleum free, 100% recyclable, readily biodegradable and grown and processed in North America.

High-oleic base oils, like those used in enviromax, reduce the tendency to oxidize. Oxidation decreases the effectiveness of fluid. The enviromax fluid has lower viscosity and greater lubricity. It creates less friction when being moved through hydraulic-elevator pumps and piping, and reduces heat gain. In some cases, overall heat gain is reduced by 33%.

| HOURS | kWh | % of total kWh | % OF TOTAL HRS. | |

| IDLE | 280.28 | 51.24 | 6.3% | 87.7% |

| RUNNING | 31.04 | 562.11 | 69.2% | 9.7% |

| VISCOSITY | 8.20 | 199.16 | 24.5% | 2.6% |

| TOTAL HOURS | 8.20 | 199.16 |

Enviromax is formulated with an International Organization for Standardization (ISO) grade of 25. Some petroleum-based products have an ISO grade of 32 and up to 68, and higher-viscosity fluids with higher ISO grades are thicker, harder to pump, typically have a greater thermal mass and add to the overall friction of the system.

A lower power requirement can also be realized with enviromax due to improved viscosity and enhanced lubricity. This is a direct result of the reduction of friction within the system due to the improved lubricity. Normally, viscosity is controlled by either external heaters or recirculating fluid through the pump without moving the elevator car in order to keep the heat at a constant temperature, usually 90-100˚F. Petroleum-based fluids require this heat to compensate for a lower viscosity index required to maintain valve performance. (Lubricating fluids naturally tend to thicken as they cool.) Because enviromax’s thermo stability is significantly greater across a broader operating range, using it may eliminate the need for temperature-control devices used to prevent oil from thickening. By turning off viscosity-control systems, an additional 30% energy savings can be realized.

For more information, contact ThyssenKrupp Elevator at website: www.thyssenkruppelevator.com. Submitted by Thomas Autcher.

Emco Load-Weighing Sensor

Elevator Motors/Materials Corp. (EMCO) now offers a load-weighing sensor that easily connects into the hydraulic line to measure the load of hydraulic elevators. The sensor is designed to be attached to the hydraulic line between the valve and piston or directly into the valve, if there is an auxiliary port. Once the sensor is electrically connected to EMCO’s programmable load-weighing control and the control sensor combination is calibrated, any changes in pressure are converted to load at the control.

The control provides three contact trip points and can be provided with a 4-20 MA or 0-10 VDC signal proportional to load. Elevator capacity can be improved by ignoring hall calls on full cabs and ignoring cab calls on empty cabs, and the system can be used on passenger or freight elevators. In addition, a cabin display can be connected to the control to provide visual and audible load indication.

For more information, contact EMCO at 80 Carolyn Boulevard, Suite 1, Farmingdale, New York 11735-1525; phone: (631) 293-4220; fax: (631) 293-2714; or e-mail: [email protected].

Electro-Mech Potentiometer Switch

Electro-Mech Components, Inc. now offers its SW44884 potentiometer switch, which offers rotary and push-on functionality for operation and control, and features a clear- light pipe shaft for front-panel illumination. The switch is designed in a compact unit for applications with limited space, and features an LED-backlit shaft with a knurled button, an alternate-action pushbutton switch and a 10,000-ohm-resistance potentiometer module. Users may also jumper the LED circuit to one of the switch circuits for LED switching. The SW44884 includes side-facing programmable-control (PC) pins for easier interface to the PC board in the next higher assembly, an operating pressure of 42 oz. (± 7 oz.), plunger travel of approximately 0.15 in. and a rated switch life of 100,000 minimum actuations.

For more information, contact Electro-Mech at 1826 Floradale Avenue, South El Monte, California 91733-3689; toll free: (888) 442-7180; fax: (626) 350-8070; e-mail: [email protected]; or website: www.electromechcomp.com.

Carlo Gavazzi Sensors

Carlo Gavazzi Inc. has introduced its new UA Series of ultrasonic sensors, which feature longer sensing ranges. With their simple teach procedure and shorter M18- or M30-diameter housing, the sensors are designed for difficult distance and level applications. The series has two output configurations. The first has two digital outputs in either negative-positive-negative (NPN) or positive-negative-positive (PNP). The second has an analog output in either 4-20 mA or 0-10 VDC, as well as one digital output in NPN or PNP. The two digital outputs can be set as standard switching outputs with two set points or as a window function. The analog output can be set with a positive or negative slope for both filling and emptying applications.

The sensors are available in four sensing distances: 400, 900, 2,200 and 3,500 mm, and come in pre-cabled or M12 connector versions. They are designed for a variety of applications.

For more information, contact Carlo Gavazzi at 750 Hastings Lane, Buffalo Grove, Illinois 60089; phone: (847) 465-6100; fax: (800) 222-2659; e-mail: [email protected]; or website: www.gavazzionline.com.

Peelle Gate Panel Patch Repair Kit

The Peelle Co. has introduced its Gate Panel Patch Repair Kit, designed to patch a hole in an elevator-ar gate panel, thereby reducing elevator downtime. The repair kit allows users more time to prepare for a replacement gate panel or complete car gate. There are two available kits: one with horizontal mesh and the other with diagonal mesh. Each kit includes two identical patches for either side of the gate panel, plastic tie wraps to install the patches to the gate panel and installation instructions.

For more information, contact Peelle at 373 Nesconset Highway #311, Hauppauge, New York 11788; toll free: (800) 645-1056; phone: (631) 231-6000; fax: (631) 231-6059; or website: www.peelledoor.com.

New High-Speed Elevator Technologies

Mitsubishi Electric Corp. now offers a new suite of technologies that enable ultra-high-speed elevators to travel faster than 1,000 mpm (60 kph) with enhanced efficiency, comfort and safety. They will be incorporated into some of the world’s fastest elevators, including the Mitsubishi Electric equipment in the 632-m-tall Shanghai Tower, currently under construction in Shanghai.

The technologies and equipment are intended for enhanced drive and controllability, safety, super-high-rise cable mechanics and passenger comfort. The suite of ultra-high-speed elevator technologies includes the following advancements.

Drive and Controllability

The traction motor incorporates a permanent-magnet motor for energy-efficient, low-noise, low-vibration operation. Also, each motor has two grouped three-phase winding coils and parallel drive systems controlled by separate control panels and a built-in converter to regenerate electricity, lowering power consumption by more than 30%. Finally, stable braking is achieved via brakes composed of two units with a hydraulic-driven clamp-type disk brake.

Safety

Safety gears, which activate the brakes by grasping the guide rails in emergencies if cables become transected, work in two stages to manage increased kinetic energy due to high speeds. Ceramic is used for the safety-gear shoe to realize high resistance to heat, abrasion and shock. Braking is stable, even if high frictional heat is generated when the safety gear is activated. Also, the hydraulic oil buffer (shock absorber) at the bottom of the elevator shaft has an advanced plunger comprising three stages for exceptional shock absorption within a shortened frame. A newly developed governor monitors elevator speed stably, even with the demand of heavy loads from ropes traveling at high speeds over long distances.

Super-High-Rise Cable Mechanics

Steel-core cable with a wider diameter allows for lightening by using lightweight sheath material. Mitsubishi Electric’s new “sfleX-rope” comprises bundles of high-intensity steel wire strands, each of which is covered with plastic. Each wire has a higher density and wider cross-sectional area than conventional rope, which helps reduce rope stretching.

Ride Comfort

A new active roller guide, which reduces vibration from guide rails and wind, enhances passenger comfort. The inside of the car remains quiet, thanks to a streamlined aerodynamic car cover and insulated cage. Also, air-pressure control helps minimize rapid changes in atmospheric pressure for reduced ear discomfort.

SCHINDLER SOLAR ELEVATOR

Schindler has introduced a solar-powered elevator, which the company says was inspired in large part by its partnership with the Solar Impulse project (ELEVATOR WORLD, September 2011). The hybrid system is designed to supply up to 100% of the elevator’s power needs from rooftop solar panels using a proprietary Hybrid Energy Manager (HEM) that utilizes batteries for solar-energy storage. Solar panels supply most of the Schindler Solar Elevator’s power requirements, which will vary depending on size and daily traffic. Backup power is provided by a one-phase grid connection. The HEM collects and stores the energy generated from the solar panels and the elevator operations to provide backup energy supply in case of a power interruption.

Eric Rossignol, R&D system project manager at Schindler, explained:

“First-customer installation testing in Barcelona proved the efficiency of the new system. The Schindler Solar Elevator not only reduces energy costs and avoids the costly power peaks caused when elevators begin each trip, but it can [also] run independently of the power grid, so it can continue operating during power interruptions or blackouts.”

The new solar elevator system uses a standard Schindler 3300 gearless machine-room-less elevator, which includes stable starting, a frequency converter with an energy-efficient standby power mode, controls that automatically switch car lights to standby mode and LED car lights. The Schindler 3300 requires no extra application engineering for adaptation to the Schindler Solar Elevator system. Intended for residential and low-rise commercial buildings, the new product is to be available in Europe and India in 2013, and the U.S. and other global markets in 2014.

Crouzet Transportation Limit Switch

Custom Sensors & Technologies (CST) has launched its Crouzet Transportation Limit Switch. The sensor is designed for various applications, including lifting systems, and is resistant to harsh environments and low temperatures. It is easy to install due to its threaded body and compact size. It features a scraper seal to prevent its plunger from sticking, operates on dual-current and medium-current circuits and has a mechanical life of up to 10 million cycles.

For more information, contact CST at website: www.cstsensors.com.

IMPROVED LED HALL LANTERN

Mathis Electronics, Inc. has released an improved version of its OmniVolt™ LED hall lantern. The MES700 unit has no switch and operates from 24-115 VAC or VDC. Furthermore, it will not glow in off mode. The improvements can eliminate such problems as hall lanterns not glowing properly and burnout due to improper voltage switching.

For more information, contact Mathis at P.O. Box 5871, Asheville, North Carolina 28813; toll free: (800) 782-4449; fax: (828) 274-5928; e-mail: [email protected]; or web-site: www.mathiselectronics.com.

Get more of Elevator World. Sign up for our free e-newsletter.