New Horizons

Aug 1, 2021

Using BIM technology to integrate VT systems

At 210 m, ATRIO Torre Norte is one of the tallest buildings in Colombia. It stands out as a beautiful addition to the Bogotá skyline, and is emblematic for the city and country.

With enormous complexity in its vertical-transportation (VT) systems and a demand for high quality, building owner ARPRO entrusted its architectural direction to renowned consulting firm Rogers Stirk Harbour + Partners (RSHP). RSHP designed and generated the basic guidelines for the tower’s VT scheme, dividing it into four zones with a total of 32 elevators and six escalators. In 2016, project builder ARPRO-ELLISDON consortium launched a private tender to select the VT system supplier for the ATRIO Torre Norte project. Otis was ultimately selected.

In the words of Consortium Director Rodrigo Rubio Vollert:

“During the bidding process, Otis demonstrated an exceptional capacity for analysis that showed a total adaptation to the project conditions, with different technologies developed and implemented in its VT systems. In the final proposal, Otis quickly caught the attention of the consortium by presenting a process in which it was possible to start the installation with partially finished hoistways, which was of vital importance to meet the accelerated schedule of this project. Likewise, its competitive prices, its high technology and enthusiastic team with empathic skills for negotiation allowed the consortium to select Otis as the supplier of this iconic project.”

Otis delivered on the promise of value by providing a high-specification product on time. The challenges that arose during the execution of the work were solved quickly by the Otis Colombia staff, who consistently showed motivation and commitment to the project, creating an efficient and collaborative environment.

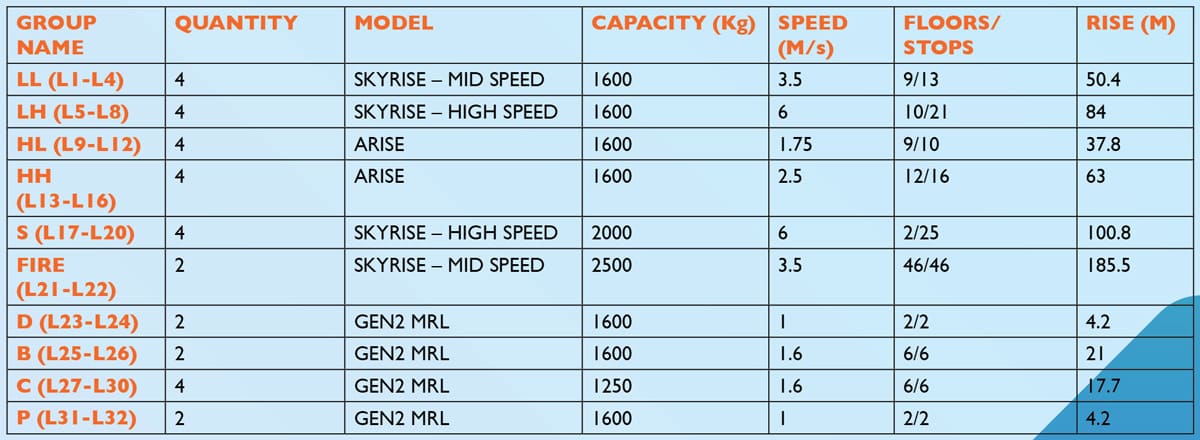

The 32 Otis elevators include 14 SkyRise® high-rise elevators, eight mid-rise Arise™ elevators and 10 Gen2® machine-room-less elevators. They are connected by Otis CompassPlus® destination dispatch technology. Otis also provided the six escalators for the project. The building interior is currently being finished for tenants, including more than 20,000 m2 for a major financial institution.

Transportation System Details

From the beginning, it was evident that project leaders considered the VT system of the highest importance to future tenants and the building’s success. This allowed for a collaborative experience involving global technical experts at Otis in the specification and quotation process.

Early project designs depicted the possibility of installing external elevators for the use of express trips using double-deck cabin technology (two cabins in a single hoistway). Designers ultimately modified the entrance to the building and eliminated the need for double-deck elevators. With its single-deck options, Otis made a full proposal, including traffic results, specifications and pricing. The traffic analysis and elevator designs continued in the study, simulation and redesign phase to ensure the building could accommodate the capacity expected by the client and its consultants. Plans were further refined by Otis’ team in Colombia, its Latin America Major Projects organization and its U.S. headquarters. Otis met the energy efficiency, safety and aesthetic requirements, and was awarded the contract in August 2016.

Two factors make this project stand out: the use of Building Information Modeling (BIM) 3D modeling software to integrate the VT system into the larger construction plans, and logistical solutions related to storing and moving materials made possible by that software.

BIM For Design and Construction Coordination

One key requirement for this project was the use of BIM coordination, which ARPRO-ELLISDON had used for the entire building. This was new technology for Otis Colombia. BIM coordination makes possible a high-precision digital simulation using LOD300 (precise geometry). This simulation allowed builders to anticipate potential problems and address them during construction, and was crucial for the exact coordination these teams required.

The BIM coordination process between the Otis Colombia team and the client’s architecture and structure team lasted just over a year. This process helped Otis demonstrate and confirm the advantages of its solutions for the building. The models developed for ATRIO Torre Norte were exclusively designed for this building, considering the special conditions of the tower and the specific requirements of the client.

BIM coordination is an excellent tool to show the client various proposals and to avoid potential complications at the time of installation. This applies to structural, architectural and technical coordination and aesthetics options alike. Throughout the process, Otis worked hand-in-hand with the structural team to locate beams, plates, supports and elements specially designed for the elevators and escalators.

Logistical Solutions

The project’s 32 elevators and six escalators were shipped in approximately 1,500 boxes of different sizes. From the beginning, Otis knew there would be challenges storing and transporting so much material to the project location. ARPRO-ELLISDON allotted Otis a large part in each of the five basements of the tower as storage space.

The Otis Colombia team used the BIM 3D model of the building to create a comprehensive plan for organizing all of the boxes and packages. This meant coordinating with the factories for the specific sizes and timing of each delivery. They were then modeled in 3D and virtually placed in the storage space provided by the customer. This work was carried out a few weeks before the equipment arrived at the construction site. In addition to establishing the position of the boxes, Otis used colors and identification numbers, which corresponded to the contract number and ID of each box, to know which material was inside each box. This process helped control the material in the field and allowed the team to avoid theft and have knowledge of the exact location of the elements required to install.

It also helped streamline deliveries. Given the location of the project in the city center of Bogotá, unloading was limited to the early morning hours. Under normal conditions, it was typical to have two freight trucks unloading at the same time, followed by two more, resulting in four deliveries per day. But with the comprehensive plan for each box, Otis was able to double that speed and unload up to eight trucks per day, helping maintain the construction timeline.

Lastly, as the equipment was stored in the basements, Otis had to coordinate with the construction tower crane to lift material to floors that were not accessible by construction elevators. Coordinating with ARPRO-ELLISDON helped the team to maintain its installation schedule and store the material close to the correct hoistway for easier installation.

ATRIO Torre Norte represents a combination of Otis’ technology, thanks to precise planning, attention to detail and a willingness to try new things to meet the customer’s expectations. This created an environment of trust and teamwork among all parties involved and led to execution of a beautiful building and a VT system to match.

Get more of Elevator World. Sign up for our free e-newsletter.