Requirements of EN 81-70,71,72 in Elevator Cabins

Nov 21, 2023

Dear readers,

In this article, we will be examining the specific requirements of standards such as EN 81-70,71,72 for lift cars.

The EN 81-70 standard establishes the operating requirements for accessible lifts. According to the standard, the dimensions of the car should be at least 1,100-mm wide and 1,400-mm deep. If the lift is to be used only for electric wheelchair access, the lift capacity can be reduced to 450 kg and the dimensions to 1,000-mm wide and 1,250-mm deep. The width of the lift car door must be at least 800 mm. However, due to local regulations, the door width is usually required to be at least 900 mm.

A handrail must be installed in the lift car on at least one wall, located at a height of 900-mm from the top of the handrail to the floor of the car and with its ends curved towards the wall of the car. The radius of the handrail should be at least 10 mm, and the cross-section should be between 30 mm and 45 mm. The handrail must be at a distance of at least 35 mm from the car wall. If the handrail is on the same wall as the control panel, it must not pass over the panel.

The mirror in the car must end at least 300 mm above the floor or be made of decorative glass.

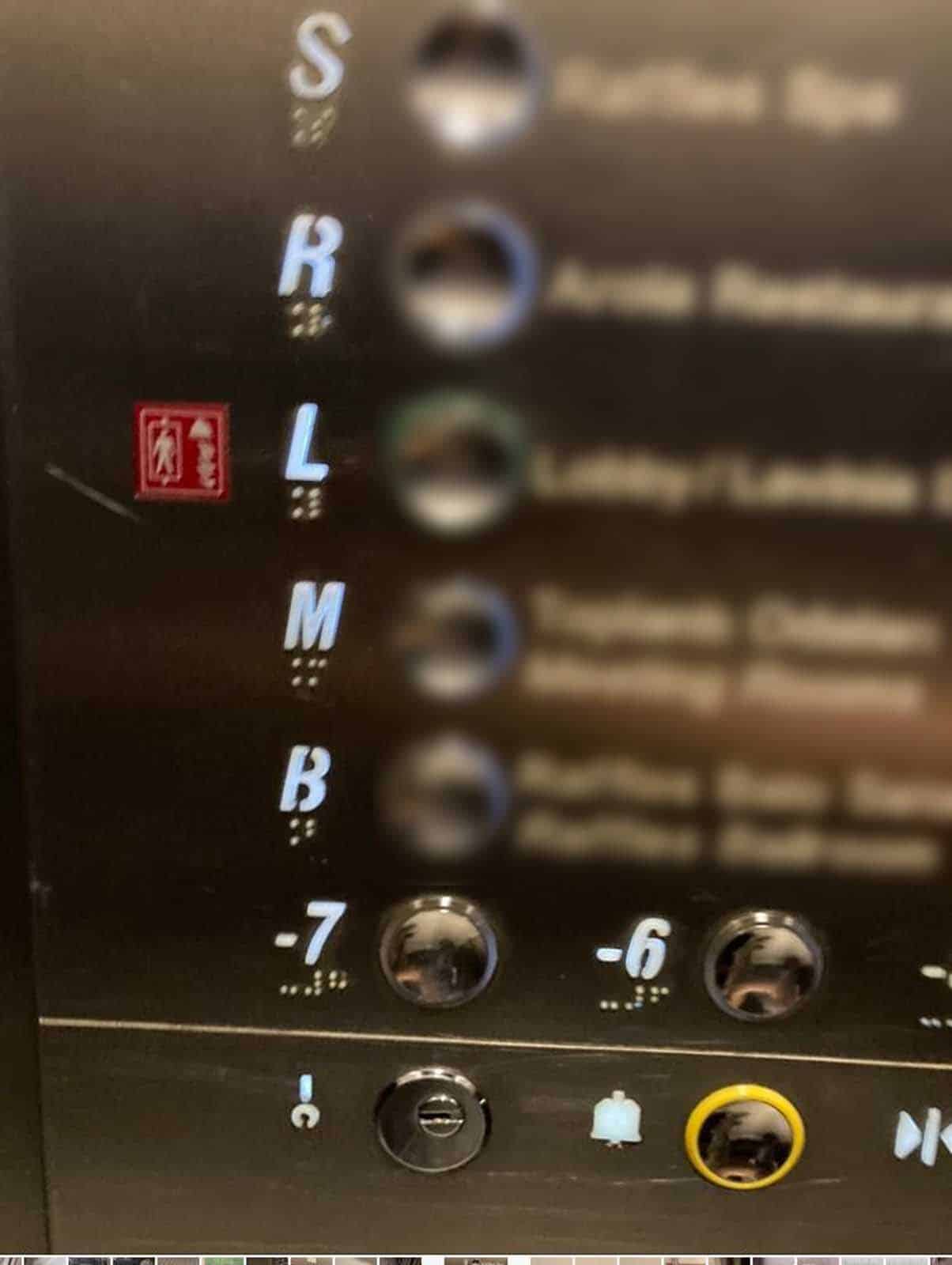

The landing buttons in the car must be indicated as -2, -1, 0, 1, 2, and the alarm button must be yellow in color and have a bell symbol. The control panel must be equipped with door opening and closing buttons. The pushbuttons must be placed on the wall of the car at a distance of a minimum of 900 mm from the center of the emergency and door control buttons to the floor of the car, and at a maximum distance of 1,200 mm from the center of the highest pushbutton to the floor. If the landing buttons are arranged horizontally, they should go from left to right; and if they are arranged vertically, they should go from left to right and then from bottom to top. The car control system must be located on the right side of the entrance in lifts with central opening doors, and it must be located on the side where the door shuts in lifts with telescopic opening doors. The button showing the main entry/exit floor of the building must be 5 mm in front of other buttons and, preferably, in green color. The embossing height of the buttons should be 0.8 mm, and the height of the operating part should be at least 10 mm. The instrument panel inside the car must be positioned in a way that ensures its centerline is at a distance of 1,600-1,800 mm from the floor of the car.

If there is a folding seat inside the car, the width of the seat should be between 400-500 mm, the depth between 300-400 mm, the carrying capacity should be 100 kg and the height from the floor of the car should be 500 mm.

The EN 81-71 standard stipulates the precautions regarding the protection of lifts against deliberate damage. Now, let’s take a look at the requirements for cars according to the EN 81-71 standard.

The walls of the car must be able to withstand the low-impact pendulum test. The fall distance of the pendulum must be 700 mm for Category-1 lifts and 1,000 mm for Category-2 lifts.

According to EN 81-71, instruments of deliberate damage are ballpoint pens, cables, ropes, wires, keys, walking sticks, chewing gum, cigarettes, lighters, pocketknives, medium-sized (200-mm long) screwdrivers, bottle caps and a person’s body weight. For Category-2 lifts, medium-sharp tools are also included in addition to these instruments.

In Category-1 lifts, the car ceiling must not be removable within 60 s with the tools mentioned above. If there are hanging points on the car ceiling where a passenger can grab onto and hang on, they must be able to withstand a weight of up to 150 kg. For Category-2 lifts, the ceiling should not include a point that can be used to grab onto and hang on.

Inside the car, the frame on which the shell is fitted must be made of non-combustible material. Ceiling, floor and wall covers must be made of limited-combustible material for Category-1 lifts and non-combustible material for Category-2 lifts. The conditions for non-combustibility and flammability are defined in the EN 13501-1 standard. The body of the car must be uncuttable by using the above-mentioned tools. The floor of the car must not cause any stumbling, even if it was incised with a sharp tool.

In Category-2 lifts, the handrail in the car must be able to withstand a 2,500-N concentrated force applied from any direction to the weakest part of the handrail.

In Category-2 lifts, the mirror inside the car must be secured to the wall of the car so as not to protrude and must be made of laminated glass.

Fittings and connections inside the car that are accessible by passengers must only be removable using special tools for Category-1 lifts. For Category-2 lifts, they should be secured in such a way that they cannot be seen by passengers.

If the ventilation openings of the car are reachable by passengers, rods of any cross-section size should not be able to go through the ventilation grille.

The lighting in the car must provide at least 100 lux on the floor of the car and on the control panel. The lighting fixtures must not be protruding and must not be reachable by unauthorized persons. The car lighting fixtures must still be safe, operational and functional when an object weighing 1 kg hits a 10-mm spot at a distance of 0.2 m for Category-1 lifts and three times for Category-2 lifts. This is called an impact test. When the car lighting is exposed to a 40-mm high flame for 60 s for Category-1 lifts and 120 s for Category-2 lifts, the flames should no longer persist at the end of the time and the soot should be easily removable. This is referred to as a fire experiment.

The buttons and indicators on the car’s control panel must have IPX3-level protection against water. IPX3 is splash resistance in accordance with the EN 60529 standard. The gap between the buttons on the control panel and the panel on which they are installed must be manufactured in a width that does not allow the equipment listed above to penetrate. The buttons and panel must be able to successfully complete the impact and fire experiments described above. The buttons, indicators and surfaces of the car must be able to withstand being cut with the tools listed above. The symbols and signs on the buttons must still be readable when they are subjected to the fire experiment described above.

The car frame, suspension gear, walls and floor, doors and sills must be resistant to corrosion, which may be caused by cleaning fluids and bodily fluids in Category-2 lifts.

The marking labels inside the car must not be removable with the tools listed above, must not become unreadable within 60 s using the same tools, and must be able to pass the fire test mentioned above.

If the lift car is equipped with an emergency exit door or hatch, in addition to EN 81-20 requirements, these doors and hatches must not be openable using the tools listed above.

The EN 81-72 standard defines the requirements for the use of firefighter lifts. Now, let’s have a look at the requirements of EN 81-72 standard for lift cars.

Firefighter lift car dimensions must be 1,100 mm in width and 2,100 mm in depth. There must be a 0.5 x 0.7 m emergency exit door on the car ceiling to be able to rescue firefighters trapped in the lift car. In addition, there must also be ladders inside and on top of the car to allow the firefighter to escape or be rescued from inside the car. In cases where there is a ladder inside the car, the distance between the ladder steps and the wall of the car must be at least 0.1 m. Portable ladders, rope ladders and ropes can be used to rescue the firefighter from inside the car, depending on the planned scenario.

The control panel of the car must not display any incorrect signals due to temperature, smoke or dampness. The control panel of the car must have an IPX3-level resistance. IPX3 is resistance against water splash in accordance with the EN 60529 standard.

In addition to the normal floor signs inside the lift car, the access floor for fire extinguishing service must be indicated on the relevant pushbutton or next to the relevant button, using the pictogram specified in Annex F of EN 81-72, to clearly demonstrate the access floor for fire extinguishing services.

Firefighter lifts must have an intercom or similar device for mutual communication between the firefighter lift car and the firefighter access floor, as well as between the firefighter lift and the firefighter lift machine room when the firefighter lift is in Phase 1 and Phase 2. The communication equipment inside the lift car and at the access floor of the fire extinguishing services must not be in the form of a telephone handset.

Get more of Elevator World. Sign up for our free e-newsletter.