Steam-Powered Elevator Engines

Mar 1, 2012

Examining early steam-powered engines and their evolution

There is, perhaps, nothing as antithetical to our conception of the modern electric elevator engine as the 19th-century steam engine. Our mind’s eye (and ear) imagines steam hissing, pistons clanking and oil dripping as a steam engine, located in a dirty, crowded mechanical room, drives a massive winding drum. The imagined noise and mechanical complexity of the engine seems to speak of the distant origins of the modern elevator. However, throughout the 19th century, steam-powered elevators were continually manufactured, as they were consistently perceived as effective and competitive alternatives to hydraulic and electric elevator engines. In fact, steam elevator engines did not begin to lose their popularity until the second decade of the 20th century. While this engine type may have lacked the design elegance of the modern elevator engine, this brief history will reveal that these machines had their own special beauty and charm.

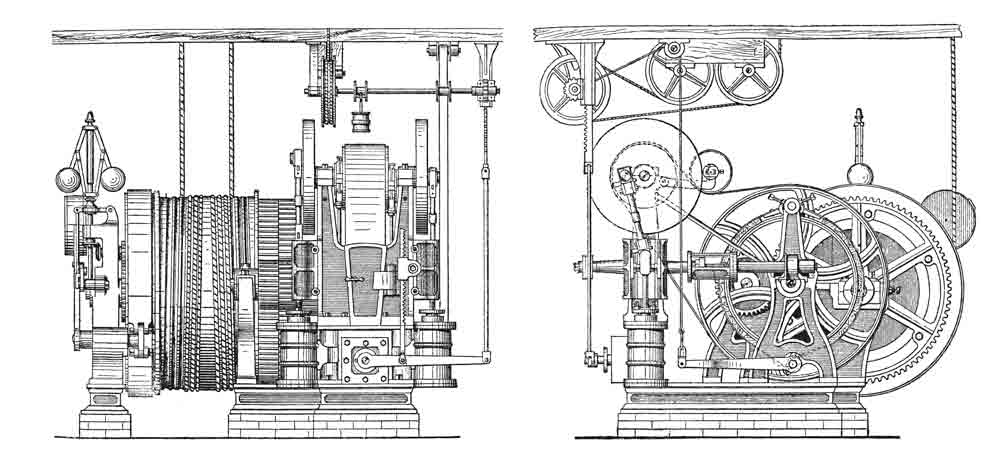

John Jallings, in his well-known book Elevators: A Practical Treatise on the Development and Design of Hand, Belt, Steam, Hydraulic and Electric Elevators (first edition 1915, revised edition 1918 and republished by Elevator World, Inc. in 1995), gave a brief history of the steam-powered elevator that included a drawing and description of the “first” steam elevator engine. According to Jallings, the engine and winding drum were mounted on separate platforms. The steam engine was a vertical, reversible two-cylinder engine, and the winding drum was driven by a worm gear. The engine and drum were linked via a leather belt that connected a 3-ft.-diameter pulley on the engine crankshaft to a 16-in.-diameter pulley attached to the winding-drum gearing.

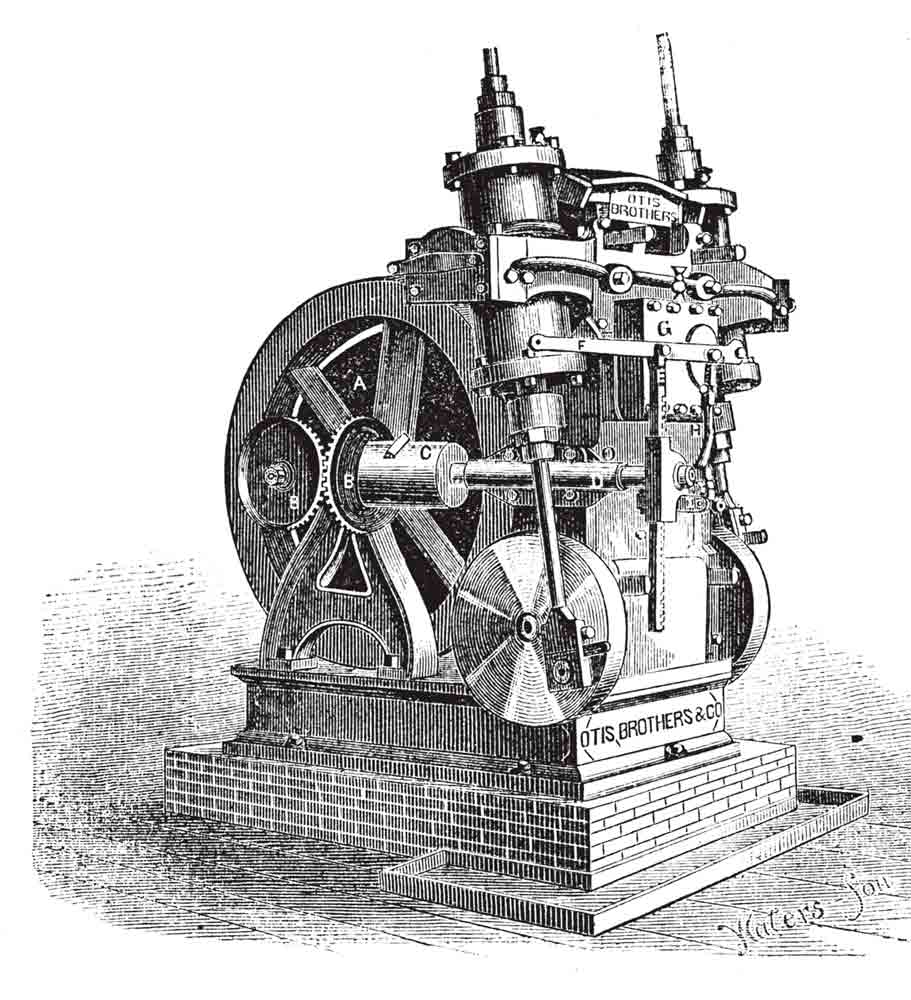

Jallings noted these early engines “occupied considerable floor space” and, “It was not long before efforts were made to design a more compact machine.” One of the earliest known images of a “compact machine” was Otis Brothers’ 1865 steam hoisting engine. This engine employed a direct-geared connection to the winding drum and featured a new automatic safety stop linked to the winding drum: after a set number of revolutions, a lever would automatically close the throttle and apply the brake, thus preventing the car from going too far up or down a shaft. The winding drum was also “enclosed in a circular case to protect the wire rope and the gearing from dirt, and from the interference of any hard substances that might cause derangement of the proper motions.” It is of interest to note the engine was depicted as resting on a raised brick base and that the base design included a floor-level reservoir located below the pistons, which was, perhaps, intended to catch excess water or oil. In addition to compact direct-geared machines, Otis also manufactured compact belt-driven steam engines. The latter design effectively combined the components of Jallings’ early elevator onto a single platform.

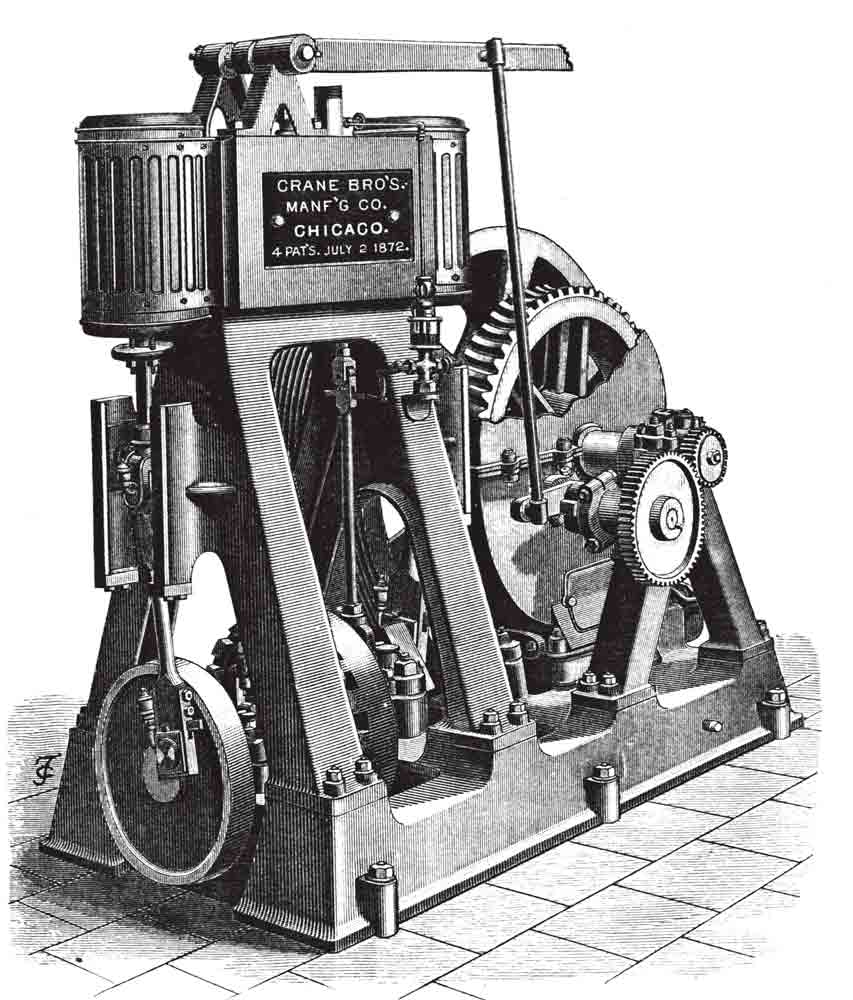

Crane Brothers Manufacturing Co. in Chicago began building steam elevator engines in the late 1860s and, by the early 1880s, manufactured both direct-geared and belt-driven engines. Crane’s belt-driven machine was designed for freight-elevator use, and its direct worm-geared machine was intended for passenger elevators. The latter was advertised in 1880 as follows:

“Hitherto, for passenger service, no steam elevator has been able to compete with the hydraulic elevator in speed and smoothness of motion. When we designed this new steam passenger elevator, we succeeded in producing a machine which, while having all of the advantages peculiar to steam, fully meets the demands of the times, in terms of both speed and smoothness of operation.”

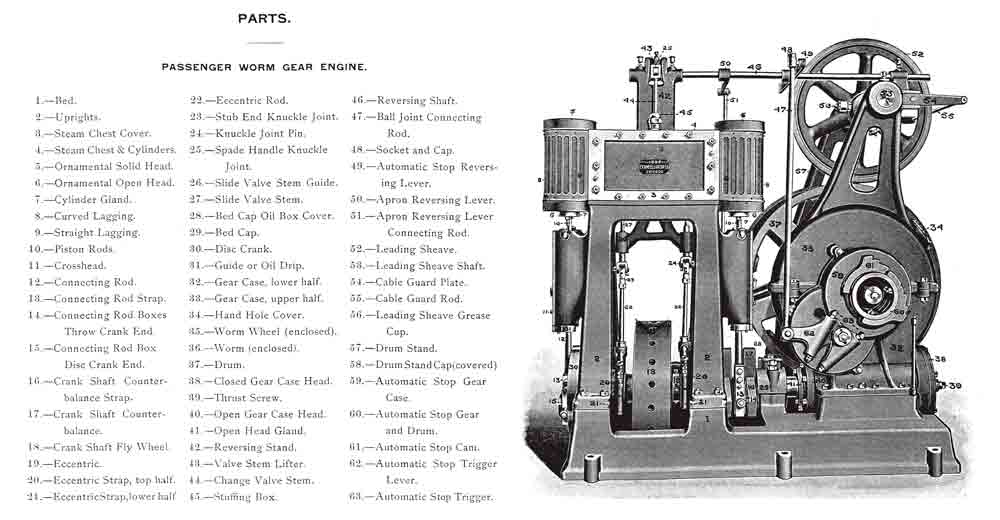

In the mid 1890s, Crane modernized and redesigned both engine types. The complexity of the company’s direct-geared steam engine was revealed in its 1897 catalog, which included a drawing of the engine with all 63 parts carefully labeled.

Other 19th-century steam-engine manufacturers included Moore and Wyman Elevator and Machine Works and Whittier Machine Co., both in Boston. Unlike Crane’s careful distinction between direct-geared engines for passenger use and belt-driven engines for freight use, Moore and Wyman built belt-driven machines it claimed were suitable for either passenger or freight elevators. Moore and Wyman’s passenger system featured a steam engine and winding drum or “hoisting machine” placed on separate cast-iron bedplates and connected via a leather belt. This arrangement recalled Jallings’ early steam-engine design; however, Moore and Wyman claimed its system was “so arranged” because this allowed the winding drum “to be located at any distance from the engine.” Although this feature implied flexibility in engine placement, the manufacturer acknowledged the engine was “generally set near the hoistway.”

By the early 1880s, Whittier Machine Co. was manufacturing a variety of belt-driven machines. A prime example was its “No. 6 double screw steam hoisting machine,” which featured the company’s patented double worm-gear system and was available in a variety of configurations. The configurations were first predicated on engine size, with the options including 7 X 8 in., 8 X 10 in. and 10 X 10 in. vertical steam engines, all of which operated at 80 lb. of steam and at 250 rpm. Each engine size could be applied to three different worm gears with thread pitches of 1.5, 2 or 3 in.; each worm gear was applicable to four different winding-drum sizes with diameters of 30, 36, 48 or 56 in. Thus, Whittier’s No. 6 engine was available in 36 different configurations, which permitted a broad range of lifting capacities (2000-14,100 lb.) and operating speeds (78-280 fpm).

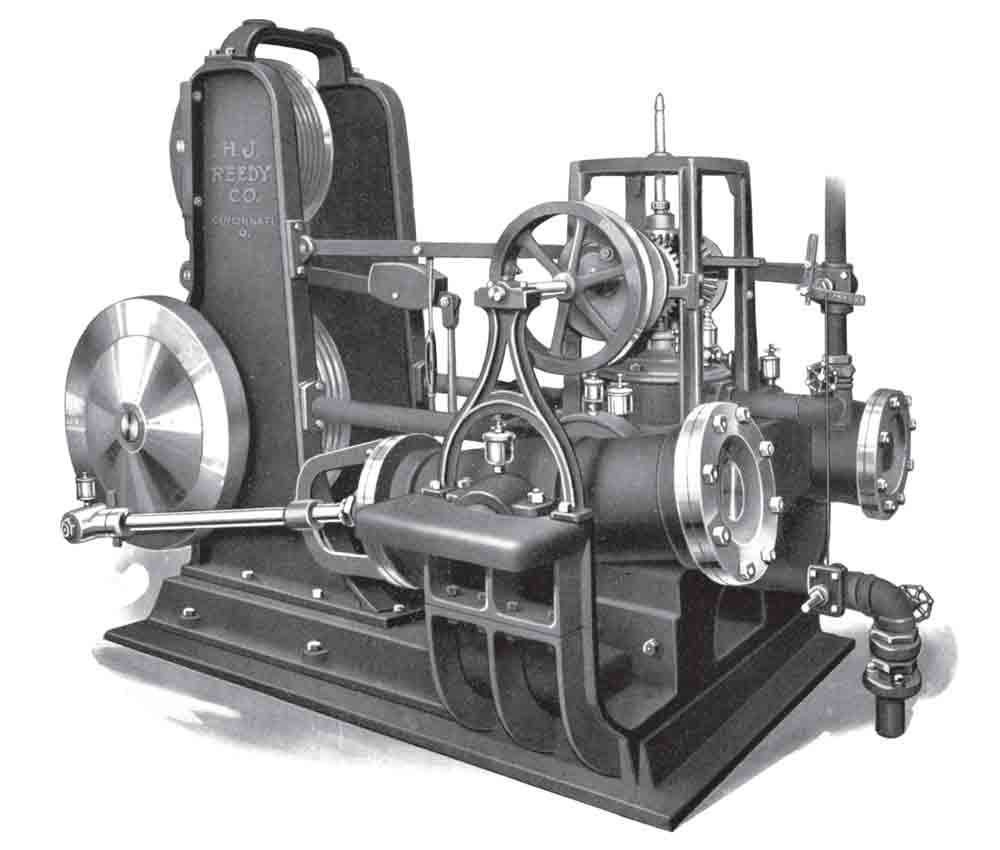

A final steam-engine type that must be mentioned illustrates the attempt to apply this technology to the traction-elevator engine that was emerging as the dominant type in the early 1900s. In its 1910 catalog, H.J. Reedy Co. of Cincinnati illustrated its vertical and horizontal steam traction engines. It claimed the latter could operate at a speed ranging “from 5 fpm to as high as 800 fpm.” Unfortunately, other than two catalog drawings, no other information was provided about these machines.

Reedy’s optimism about the continued use of steam power to drive elevator engines was, of course, misplaced. Eight years later, John Jallings observed – not without a gentle criticism of the emerging technology:

“The introduction of the electric elevator and its economical operation and maintenance gradually eliminated the steam elevator, and today there is hardly one to be found. But the fact remains that it was in its day a very efficient machine and more durable than the electric, the electric parts of which deteriorate rapidly.”

John Jallings, Elevators: A Practical Treatise on the Development and Design of Hand, Belt, Steam, Hydraulic and Electric Elevators, the “first” steam elevator engine

Otis Brothers’ Belt-Driven Steam Hoisting Engine (1878)

Crane Brothers Direct-Geared Steam Hoisting Engine (1880)

Crane Brothers Belt-Driven Steam Hoisting Engine (1880)

Crane Brothers Direct-Geared Steam Hoisting Engine (1897)

Moore and Wyman Belt-Driven Steam Hoisting Engine (1885)

Whittier Machine Co. No. 6 Double Screw Steam Hoisting Machine (1884)

H.J. Reedy Vertical Steam Traction Engine

H.J. Reedy Horizontal Steam Traction Engine

Get more of Elevator World. Sign up for our free e-newsletter.