A look back at a time when a new challenger arrived as competition to the original Otis Escalator

Between January 1934 and June 1935, several major American newspapers carried stories announcing three important escalator installations with a combined value of US$1.25 million. It would seem reasonable to assume that these announcements, appearing amid the Great Depression, would have been welcome publicity for Otis. After all, Otis had been a pioneer in the development of moving stairways and, in fact, owned the trademark on the name “escalator,” ensuring that users would associate this transportation system with the company. However, in these instances, Otis was very likely less than pleased with the press coverage. Its unhappiness was because, despite branding success that resulted in all moving stairways consistently referred to as escalators, all three installations involved Westinghouse “Electric Stairways.”

Westinghouse had entered the vertical- transportation marketplace in the mid-1890s, building electric motors designed for elevator use. By the early 1920s, the company manufactured a full line of elevator motors and controllers. In 1927, Westinghouse expanded its industry engagement with the acquisition of Kaestner & Hecht Co. of Chicago. The following year, Kaestner & Hecht became Westinghouse Electric Elevator Co. The Chicago Tribune described the “new” enterprise as follows: “The company will operate as a separate unit, with financial, sales, engineering and manufacturing headquarters in Chicago, and sales offices and service shops in all the principal cities of the United States.”[1] While the company’s primary focus was the development of electric elevators (building on past efforts of Westinghouse and Kaestner & Hecht), by the early 1930s, it had also begun work on the development of an electric stairway. This article will examine the initial phase of this effort.

The development process was apparently led by James Dunlop, chief design engineer for Westinghouse Electric Elevator. Between April 1934 and January 1939, Dunlop filed 11 patent applications concerning electric stairways; four additional related applications were filed by other Westinghouse engineers. These 15 patents, awarded between October 1935 and September 1940, addressed a variety of topics associated with escalator design: chains and gears, combplates, steps, handrails, balustrades and skirts. The patent text provides numerous insights into escalator operation in the 1930s and perceived operational concerns, including the elimination of unwanted noise:

“Moving stairways are usually installed in department stores, railway stations and other buildings in which large numbers of persons are to be transferred from one floor to another. Obviously, it is desirable to have such moving stairways operate as quietly as possible. . . . However, in spite of careful construction of the chains, it has been found that the impact between the chain rollers and the sprocket wheels when in operation usually produces a very objectionable noise.”[2]

In a similar fashion, several patents addressed other issues that arose from daily use:

“In constructing moving stairways. . . considerable difficulty has always been encountered in setting up the balustrading for the stairway steps, particularly in mounting the lower panel or skirt on the balustrading in correct position with relation to the sides of the steps. If the opening between the balustrading skirt and the sides of the stair runway is too wide, dirt and small objects are liable to get between the skirt and the moving steps and cause trouble. Also, if the opening is too wide, the passengers on the steps may get the ends of their canes or umbrellas caught in the opening, and, in extreme cases, even parts of a passenger’s shoe may be caught between the skirt and the steps, resulting in danger for the passenger and trouble in operating the steps. On the contrary, if the opening between the steps and skirt is too small, the steps may, after being operated a while, wear in such manner as to impinge against the skirt, with resulting noise and difficulty in operation.”[3]

The proposed solution to these design challenges offered insights into past solutions:

“Heretofore, the matter of correctly adjusting the position of the skirt with reference to the steps has been [affected] by the use of shims between the frame and the skirt. The use of shims makes it difficult to assemble the balustrading and the skirt in correct position adjacent to the steps and also makes it difficult to readjust the position of the skirt. These difficulties arise because, in preparing the balustrading and the frame, it is necessary to have all the bolt holes accurately placed in the various parts so they will line up correctly when the balustrading and skirt are assembled. Furthermore, the shims are difficult to handle and keep in place while the bolts are being loosened and tightened here and there as the parts are assembled and adjusted. Therefore, it is an object of my invention to provide a balustrading construction by means of which the balustrading skirt may be set up in its correct position with reference to the steps in a short time with a minimum amount of effort, and by means of which the skirt may be quickly and easily readjusted to its correct position whenever it is found that the steps are moving along a line too close or too far away from the skirt.”[3]

The overall operation of escalators was also addressed with regard to energy conservation:

“In many moving stairway installations, the load varies considerably throughout the day by reason of the fact that there may be periods at various times when no passengers use the stairways. This is particularly true in railway stations, and, in such cases, the stairways often remain idle for considerable periods between the arrival and departure of trains. If the stairways are stopped entirely, the passengers think they are out of service and, after giving them a glance, make use of the stationary stairways. However, if the stairways are moving, even though slowly, the passengers see they are in operation and proceed to ride on them. Therefore, it is an object of my invention to provide a moving stairway which will automatically respond to the variations in the periods when the stairways are not needed and to the periods when they are needed. . . . Another object is to provide a motor and control system for operating moving stairways which will cause the stairways to operate at low speed when passengers are not being carried and to operate at high speed when passengers are being carried.”[4]

In this instance, the escalator’s speed was to be controlled by a “light sensitive device” located at the entrance (Figure 1).

The first Westinghouse Electric Stairways were installed in West Philadelphia’s Pennsylvania Station. Built between 1931 and 1933, the building replaced an older railroad station and featured five units. It is of interest to note that the first reference to this installation dates from 1931, several years prior to the first patent applications. This speaks to the speed with which Westinghouse sought to bring its machines into the marketplace. In fact, the production and installation of these machines throughout the 1930s paralleled their design and development. In January 1934, the Pittsburgh Press announced Westinghouse had received a US$500,000 contract to provide 20 electric stairways for Marshall Field and Co.’s State Street store in Chicago.[5] Construction began in February, with the installation of the escalators occurring in April and May. The Chicago Tribune claimed that new system replaced “10 elevators in the store service” and that each machine had a capacity of 10,500 persons per hour.[6] While the suggested capacity significantly exceeded that projected by Westinghouse — 8,000 persons per hour for a 48-in.-wide stairway – a December 1934 Marshall Field’s advertisement claimed the stairway’s peak capacity was 10,000 persons per hour. The same advertisement reported:

“It’s the first Christmas for our gorgeous new Westinghouse Electric Stairways. But, already, they have become one of our most popular services. . . keeping everything running smoothly these big, busy shopping days. Streamline in appearance, streamline in performance, no traffic jams, green lights all the way to Santa’s headquarters — Fourth Floor.”[7]

The streamlined appearance of the electric stairways reflected contemporary Art Deco design ideas (Figure 2). While the advertisement copy clearly identified the moving stair by its proper brand name, the ad’s title — “10,000 People in One Hour Went Up These Escalators to See Santa” — doubtless gave the local Otis company representative heartburn.

The misidentification of Westinghouse Electric Stairways as escalators continued throughout the decade. In May 1934, the Los Angeles Times announced that Bullock’s department store had a contract with Westinghouse for 10 “electric escalators” at a cost of US$250,000.[8] The installation was completed in October, and, reflecting the challenges presented by the Great Depression, the newspaper noted that the work had “been furnishing employment for 200 men.”[9] The paper also reported, “These noiseless modern electric stairways take the place of 12 capacity elevators. [Their] moderate speed and special treads allow a large margin of safety in operation.”[9]

In June 1935, Westinghouse received another major commission in Chicago. Carson Pirie Scott & Co. followed Marshall Field’s lead and installed a full suite of electric stairways (also costing US$500,000). The Associated Press coverage stated the stairways would “be the widest obtainable” (48 in. wide) and thus provide “ample room for three persons on each step.”[10]

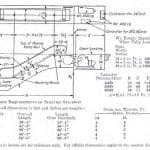

The Westinghouse Electric Stairway experienced continued commercial success throughout the 1930s. The Westinghouse General Catalog 1939-1940 referenced installations in Philadelphia; NYC; Chicago; Washington, D.C.; Los Angeles; Buffalo, New York; Camden, New Jersey; and Birmingham, Alabama; and Richmond, Virginia. The catalog claimed, “In development of the electric stairway, Westinghouse used principles proved in engineering practices.”[11] These “principles,” in the context of escalator design, included step treads with closely spaced cleats, ball bearings or roller bearings to minimize lubricating requirements, canvas step rollers (for quiet operation), and metal or wood balustrading.[11] The stairs were also described as “standardized in all important respects” with an operating speed of 90 ft/min and a 30° angle of incline. The stairs were available in three widths: 24 in. (4,000 people per hour), 36 in. (6,000 people per hour) and 48 in. (8,000 people per hour). The catalog included a schematic plan, section drawing and associated design data, all of which were intended to provide baseline information for architects and engineers (Figure 3).

While the Westinghouse Electric Stairway was the first challenger to the Otis Escalator, it was not the only competition. In 1945, Multiscope, Inc. of Coffeyville, Kansas, introduced the Motorstair. In 1949, Multiscope was acquired by The Peelle Co. and continued to build Motorstairs until 1965, when their escalator division was purchased by the Haughton Elevator Co. Haughton rebranded the machines with the less poetic name of “Moving Stairs.” Of course, all these machines were known to the vertically traveling public as escalators.

- Figure 1: Westinghouse Electric Stairway[4]

- Figure 2: Westinghouse Electric Stairway in Marshall Field and Co.’s State Street store in Chicago

- Figure 3: “Westinghouse Electric Stairway Specifications”[11]

References

[1] “Elevator Firm Takes Name of Westinghouse,” Chicago Tribune (August 3,

1928).

[2] James Dunlop. “Chain Gear,” U.S. Patent No. 2,044,158 ( June 16, 1936).

[3] James Dunlop, “Moving Stairway,” U.S. Patent No. 2,193,583 (March 12,

1940).

[4] William F. Eames, “Moving Stairway,” U.S. Patent No. 2,106,833 (February

1, 1938).

[5] “Given Chicago Contract,” Pittsburgh Press ( January 12, 1934).

[6] “New Field Escalators Dedicated,” Chicago Tribune (May 25, 1934).

[7] “10,000 People in One Hour Went up These Escalators to See Santa,”

Chicago Tribune (December 21, 1934).

[8] “New Bullock’s Improvements: Ten Electric Escalators to be Installed at

Cost of $250,000,” Los Angeles Times (May 19, 1934).

[9] “New Electric Escalators for Bullock’s Ready,” Los Angeles Times (October

17, 1934).

[10] “Work Under Way on Escalators in Carson Store,” Chicago Tribune ( June

9, 1935).

[11] Westinghouse General Catalog 1939-1940, Westinghouse Electric &

Manufacturing Co. (1939).

Get more of Elevator World. Sign up for our free e-newsletter.