A guide to maintaining this Peelle equipment

Value: 1 contact hour (0.1 CEU)

This article is approved for Continuing Education by NAEC for CET® and CAT®.

EW Continuing Education is currently approved in the following states: AL, AR CO, FL, GA, IL, IN, KY, MD, MO, MS, MT, NJ, OK, PA, UT, VA, VT, WA, WI and WV | Canadian Province of BC & ON. Please check for specific course verification of approval at www.elevatorbooks.com.

Learning Objectives

After reading this article, you should have learned about:

- The maintenance of vertical sliding doors

- Chain lubrication

- Differences between vertical sliding and passenger doors

- The assessment of door panels

- The assessment of door controllers

Maintenance of vertical sliding doors, traditionally furnished on freight elevators, is focused on several electrical and mechanical components that drive the steel panels. Vertical sliding doors, properly maintained, can last the life of the building. However, due to their frequent use and the nature of freight elevators, they require the same attention as those that carry passengers. Depending on how critical the freight elevator is to the operation of the business, maintenance might be even more important for the former, because there could be fewer freight elevators, and a shutdown could cripple operations.

Considering that 80% of shutdowns are door-related, vertical sliding door maintenance should be given proper attention and is concentrated on a few key electrical and mechanical components.

Proper maintenance includes a process of routine examination, lubrication, cleaning, adjustment and replacement of parts. Maintenance serves the purpose of ensuring performance in accordance with applicable code requirements.

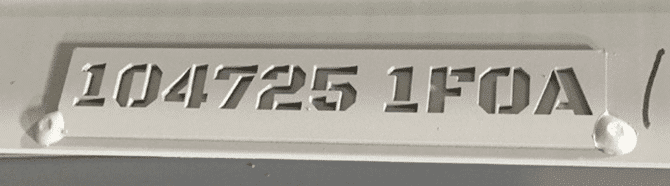

Where any alteration, replacement of parts, repair or maintenance is made, it should not diminish the level of safety that existed prior to the change. To update equipment as near as possible to the latest code, refer to “Modernization Manual 205” and “Modernization Guide 312,” available at peelledoor.com. The relevant AHJs should be checked with when undertaking this work. Before contacting The Peelle Co., locate the six- or seven-digit Peelle job number on your door controller, door guide rails and shoe bars so that the company may confirm replacement parts with the original job.

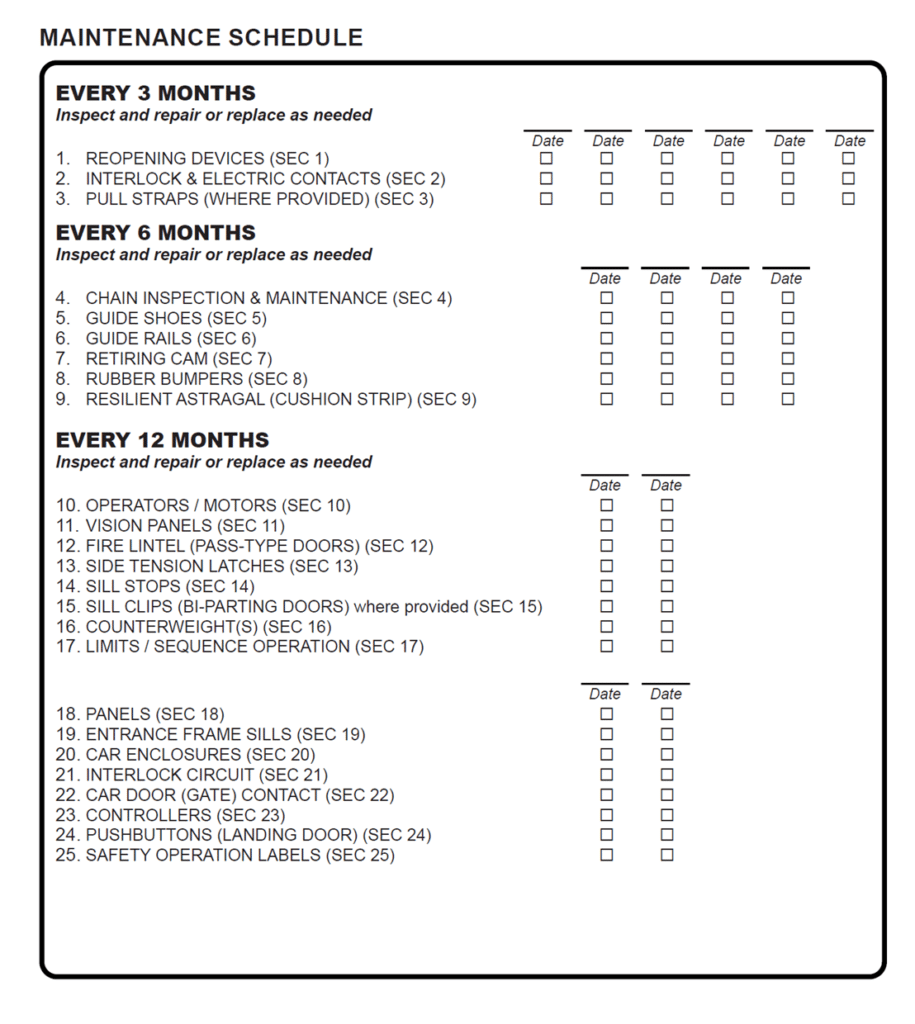

Maintenance for elevators is expected once a month and must include the vertical sliding hoistway doors. Periodic inspections should be done at least every six months per ASME A17.1/CSA B44 Section 8.11.2.1. Maintenance should be performed by persons with elevator and elevator door training. Maintenance on doors wider than 10 ft may require two or more elevator maintainers.

This safety instruction is for authorized service personnel only:

- Ensure all elevator safety protocol is followed before accessing the hoistway.

- Ensure personal protective equipment (PPE) is worn.

- The doors should be manually unlocked and opened only for maintenance and in emergencies.

Accessing Doors From the Landing

Doors Without Access Operation

To open standard doors with a single lock, perform the following steps:

- Open unlocking device using key.

- Pull release chain to unlock door.

- Hold release chain and push downward on lower panel. (For slide-up doors, push upward.)

- Once the door is open approximately 3 in., release the chain and proceed to open the doors.

Before leaving the hoistway, close the doors slightly. This will allow you to easily close them fully when service is complete.

To close the doors, perform the following steps:

- Push doors closed.

- If provided, set the unlocking device switch to the “RUN” position.

- Close the unlocking device cover.

Large Doors With Two Locks

Ensure two service personnel are available. Large doors have locks on both sides. To open them, perform the following steps:

- Move car between landings; car cannot be in a landing zone.

- Open unlocking devices using a key.

- Set the unlocking device toggle switch to the “ON” position.

- Pull both release chains to unlock the door.

- Hold release chains and press the door open button.

- Once door is fully open, set the unlocking device toggle switch to the “STOP” position. This will disable landing door operation only. Power to the landing door is still present.

The car cannot be at another floor zone (multizone) for operation. Make sure it is away from any landing.

To close the doors, perform the following steps:

- Reset the unlocking device toggle switch to the “RUN” position.

- Pull both release chains to unlock the door.

- Hold the release chains and press the door close button.

- Once the doors are fully closed, close the unlocking device covers.

Opening the Door From the Car Top

Ensure two service personnel are available if the door has locks on both sides of the opening. Stop the car in a position that allows service personnel to reach the door lock(s) (roller[s]) and also reach the top of the lower door panel. The locks are on the sides of the opening and at approximately the center of the opening height. Do the following:

- Press and hold the roller attached to the door lock toward the hoistway wall.

- Press down on the lower door panel. Once the door opens approximately 2 in., release the roller and proceed to manually open the door. (For slide-up doors, push the upper panel upward.)

Opening the Door From Within the Pit

Doors With a Single Slide Lock

Prior to entering the pit, ensure a pit ladder is present and that you can reach the door lock (roller) while on the pit ladder. Do the following:

- To open the door, climb the pit ladder, and press and hold the roller attached to the door lock toward the hoistway wall.

- Press down on the lower door panel. Once the door opens approximately 2 in., release the roller and proceed to manually open the door. (For slide-up doors, push the upper panel upward.)

Wide Doors With Locks on Each Side (Double Locks)

Ensure two service personnel are available if the door has locks on both sides of the opening. One service person shall remain on the landing side of the opening at all times if any service personnel are entering the pit. Prior to entering the pit, ensure a pit ladder is present and that you can reach the door lock (roller) while on the pit ladder. Then, the following may be performed:

- Mechanic in the shaft should climb the pit ladder.

- Press and hold the roller toward the hoistway wall.

- Mechanic at the landing (hall side) will press down on the lower door panel (or lift for slide-up doors).

- Once the door opens approximately 2 in., release the roller.

- Repeat the prior steps to unlock the opposite side of the door.

- The mechanic at the landing should proceed to manually open the door.

The zoning switch inside the unlocking device (when furnished) will need to be set to “RUN” once service is completed at the door being opened.

Chain Lubrication

Chain lubrication has been debated among mechanics for years. The debate is related to what to lubricate, as well as which lubricant to use. Maintenance technicians must also be aware that over-lubrication can affect door performance. Not only does lubrication require proper attention during the maintenance process, it should also follow the manufacturer’s recommendations. Poor lubrication will lead to poor operation, which can contribute to the overall elevator performance.

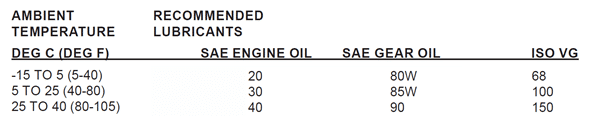

Peelle chains require lubrication to resist wear of the pin/bushing joint. Lubricate contact surfaces to prevent rust and corrosion. Petroleum oil without additives is recommended. Table 1 provides a guideline for selecting the proper lubricant viscosity at various ambient temperatures.

Do not use grease when applying lubricant. Steps are:

- Create slack in or remove chain prior to lubrication. This allows the lubrication to penetrate the critical pin/bushing area.

- Apply lubricant to the upper edges of the link plates, preferably by dripping it onto the chain somewhere over the top of a sheave or sprocket.

- Lubrication flows to the pin/bushing area between the link plates.

- Lubricate directly to each row of chain link plates.

- Do not lubricate the rollers.

- Avoid any over-lubrication to ensure proper chain/sheave traction.

Guide Shoes

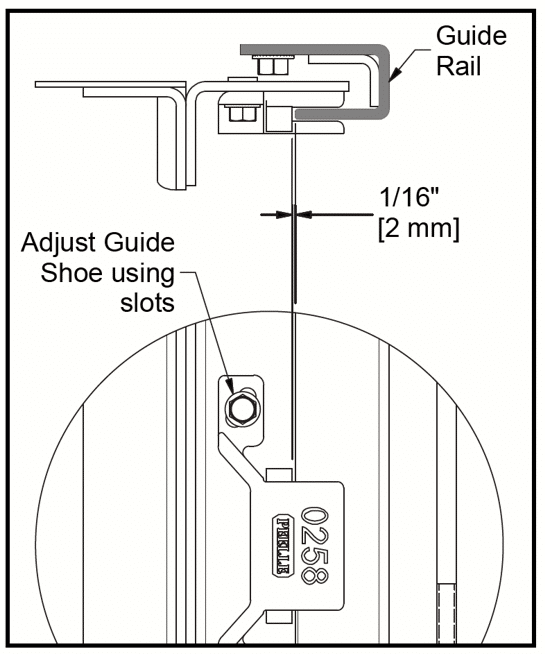

Vertical sliding door panels are heavier than their passenger door counterparts; each panel is furnished with four guide shoes that slide on guide rails; this mechanical interface requires the correct adjustment during the original installation, as well as during ongoing maintenance. The following should be observed and performed:

- Make sure there are no more than four missing guide shoes per panel.

- Make sure the guide shoes are not worn enough to permit the door panels to come out of the door rails at any position of their travel.

- Look for excessive side-to-side play: panels should fit within the guide rails with 3 mm overall side-to-side play, both at the top shoes and at the bottom shoes of each panel.

- Push the panel all the way to the left, then measure side-to-side play as the panel is pushed all the way to the right. Shoes must be replaced if overall side-to-side play is 8 mm or more.

Guide Rails

- Lubricate rails lightly with elevator hydraulic oil, automotive #10 oil or (in atmospheres containing dust) a dry lubricant. Avoid using grease and silicon-based lubricants.

- Do not let lubricant get on chains or inside contacts.

- Replace rails if damaged or broken.

- If the counterweight guide track on the car door (gate) rail is damaged, replace the complete car door (gate) rail assembly, as the counterweight guide track is permanently welded to the car door (gate) rail.

Retiring Cam

- Adjust the V-belt for 13-mm deflection.

- The motor crank must lift toward the center of the car.

- Maximum lift of crank should be 3 or 9 o’clock (90° 6 o’clock).

- Lubricate pivot points with automotive #10 oil.

- Clean controller contacts for the retiring cam relay.

Resilient Astragal (Cushion Strip)

Replace the resilient astragal (cushion strip) if it is missing from the upper panel or if it fills the gap between panels when closed. Also replace it if significant wear and tear are observed.

Operators/Motors

- Inspect pinions and gears for worn components.

- Ensure both landing door motors are working and rotating in opposite directions.

- Listen for excessive noise, and squeaking or grinding sounds.

- If the sheave does not turn or turns erratically, check for a worn motor pinion (part of motor) or motor burnout.

- Replace the motor if it is burned out.

- Door operators allow motor replacement without removing the sheave or chain.

- On narrow-return Peelle #0587 door operators, loosen 3 mm but do not remove the bearing shaft bolt to remove the motor for replacement.

Lubrication

- The pinion and gears require a small amount of grease; do not apply grease to the sheave.

- Motor bearings and sheave bearings are permanently lubricated (no lubrication required).

- Lubricate sheaves fitted with a grease fitting. Grease the fitting moderately at six-month intervals for heavy use or one year for normal use. Do not over-grease.

Biparting Doors

Hoistway Panels

Look for the following:

- Broken, bent or sprung members

- Structural defects

- Missing or worn guide shoes

- Damaged or missing toe guards

- Missing fire lintels (pass-type doors)

- Missing vision panel glass and grille

- Damage and corrosion

- Binding or catching

- Doors creeping apart (moving by themselves): if this is observed, check for missing panel parts (fire lintel, toe guard or balance weights).

Maintenance

- Replace missing or damaged parts as needed.

- Full panel replacements are recommended if a panel is beyond repair or has been punctured.

- Doors manufactured prior to 1955 should be replaced with completely new doors.

Car Door (Gate) Panels

Door panels on a freight elevator, even when maintained properly, sometimes need to be replaced due to damage, misuse, abuse, environmental factors, etc. It is not always obvious what to look for when assessing panels for replacement, but the assessment should go beyond the electrical and mechanical components. Openings, if any, in the car door (gate) panel must reject a 50-mm ball. Additionally, look for:

- Broken, bent or sprung members

- Structural defects

- Missing or worn guide shoes

- Missing vision panel glass and grille

- Damage and corrosion

- Smooth operation

- Panels that open fully and close fully

- Panels that do not creep open

Maintenance

- Replace damaged panels.

- If panels creep open, adjust car door (gate) counterweight.

Retiring Cam and Interlock Sequence

To move the elevator, the following sequence must take place:

- Car door and landing doors must be closed at all floors (GC and DC circuits closed).

- The elevator controller initiates retiring cam (RC). Then, the retiring cam lifts away from the roller (landing door locked and DI circuit closed).

Car Door (Gate) Contact

Contact remains made when activated by the counterweight cam. Move and shake the counterweight and car door (gate) panel (in closed position) and use a continuity tester. Check that the car door (gate) contact opens (stops the running elevator) when the car door (gate)/car door panel is lifted 50 mm from the car floor. Also look for:

- Excessive play in the counterweight as the car door (gate) contact is activated by the counterweight

- Missing covers

Maintenance

- Adjust the cam and contact to ensure the contact remains made while the car door (gate) is closed.

- Replace the counterweight guide shoes if the counterweight is loose or floppy.

- Replace covers.

- Clean contacts using alcohol swabs.

Controllers

The elevator industry has a long and proud history of innovation. Vertical sliding doors have progressed from having relay-logic controllers to programmable logic controllers (PLCs) to wireless controllers, each with unique maintenance needs. Sometimes, the control system and components they drive can be maintained to provide proper performance; when the controller has reached the end if its lifecycle, the best solution is upgrading to current technology.

Jumpers are not recommended, but if they are present, remove all lock jumpers before putting the elevator back into normal operation. Hoistway- and car-door bypass switches on the controller must be open before putting the elevator back into normal operation per A17.1/B44 Section 2.26.1.5.

Wireless VVVF Door and Car Door (Gate) Controllers

Replace missing covers on wireless variable-voltage, variable-frequency (VVVF) door and car door (gate) controllers as necessary and tighten any loose terminals.

PLC Door and Car Door (Gate) Controllers

The fuse connectors in programmable-logic-controller (PLC) door and car door (gate) controllers in humid, hot, salty environments should be checked carefully. Hoistway wires that are very old or not covered in plastic should be considered for replacement, especially inside pipes.

Relay-Logic PLC Door and Car Door (Gate) Controllers (Prior to 2002)

- The fuse connectors in PLC door and car door (gate) controllers in humid, hot, salty environments should be checked carefully. Hoistway wires that are very old or not covered in plastic should be considered for replacement, especially inside pipes.

- The TP 3-min timer protects the retiring cam motor and serves as a backup protection timer for the 30-s door/car door (gate) motor timer.

- If the TP timer circuit needs to be reset, check the interlock keeper hook position. The keeper hook might be caught “nose-to-nose” against the interlock ratchet, allowing the door operator motors to run for 3 min and trip the TP timer. Neither the door/car door (gate) motors, nor car will operate. With the doors closed, the keeper hook should be reset 6 mm above the interlock ratchet by adjusting the chains/chain rod. Do not move the vertical position of the interlock.

- If a 10-A fuse is blown, a short-circuit other than a door/car door (gate) motor is usually the cause. Any short must be corrected, and the fuse must be replaced to resume normal operation.

- Check at least once a month: reversing starters (Peelle #07628 power contactors) should be carefully examined with the power off. They are mechanically interlocked with moving nylon pivots that might wear out. Some nuts on the contactor microswitches might be loose. Check openings at the top of each contactor for foreign material. Check the silver contacts. The retiring cam relay (Peelle #07623) also has silver contacts. If it is necessary to clean the contacts, turn the power off and clean with contact cleaner and a clean cloth. Do not file contacts. Vacuuming is OK, as there are no printed circuit boards present.

- A door controller manufactured before 1969 should be upgraded with a new, replacement controller to reduce motor burnout instances. The cost of a new controller is less than that of several motor replacements.

How to Clean and Disinfect

- Wear disposable gloves.

- Clean surfaces using soap and water to reduce the number of germs, dirt and impurities on the surface, then use disinfectant to kill germs on surfaces.

- Practice routine cleaning of frequently touched surfaces.

- More frequent cleaning and disinfection may be required based on the level of use.

- Surfaces and objects in public places, such as shopping carts and point-of-sale keypads, should be cleaned and disinfected before each use.

Disinfecting Painted and Stainless-Steel Panels

Using Environmental Protection Agency (EPA)-registered household disinfectants is recommended for both these surfaces. For stainless-steel panels, isopropyl alcohol is also recommended. Follow the instructions on the label. Many products recommend keeping the surface wet for a period. Keep in mind precautions such as wearing gloves and making sure you have good ventilation during use of the product.

Peelle recommends the use of isopropyl alcohol or any EPA-registered household disinfectant. Follow the instructions on the label. Many products recommend keeping the surface wet for a period of time. Keep precautions such as wearing gloves and making sure you have good ventilation during use of the product in mind.

Finishing Shine

- Use recommended stainless-steel cleaning product Sheila Shine or equivalent.

- Follow manufacturer instructions for best cleaning results.

Staff Considerations When Cleaning

- Regular cleaning staff can clean and disinfect community spaces.

- Ensure they are trained on appropriate use of cleaning and disinfection chemicals.

- All involved in the cleaning process (including handling trash) should wear disposable gloves and gowns.

- Additional PPE might be required based on the cleaning/disinfectant products being used and whether there is a splash risk.

- Gloves and gowns should be removed carefully to avoid contamination of the wearer and surrounding area.

- Wash your hands often with soap and water for 20 s immediately after removing gloves and after contact with a person who is sick.

- If soap and water are not available, and hands are not visibly dirty, an alcohol-based hand sanitizer that contains at least 60% alcohol may be used. However, if hands are visibly dirty, always wash hands with soap and water.

New York Local Maintenance

Peelle’s New York operation provides maintenance service in the Local 1 elevator market, including parts delivery, emergency shutdown response service, repair service, routine maintenance on freight doors and gates, installation, modernization and field survey assistance.

Learning-Reinforcement Questions

Use the below learning-reinforcement questions to study for the Continuing Education Assessment Exam available online at www.elevatorbooks.com or on p. 124 of this issue.

- Proper maintenance of biparting doors ensures more elevator uptime. What percentage of elevator shutdowns are predominately door related? Why?

- What are the appropriate timeframes for proper elevator maintenance of vertical sliding door components? Keep in mind that this schedule is a recommendation; based on usage, the maintenance technician might decide frequent attention is required.

- Both door and gate panels offer many years of service. However, what are the signs that indicate the need for their replacement?

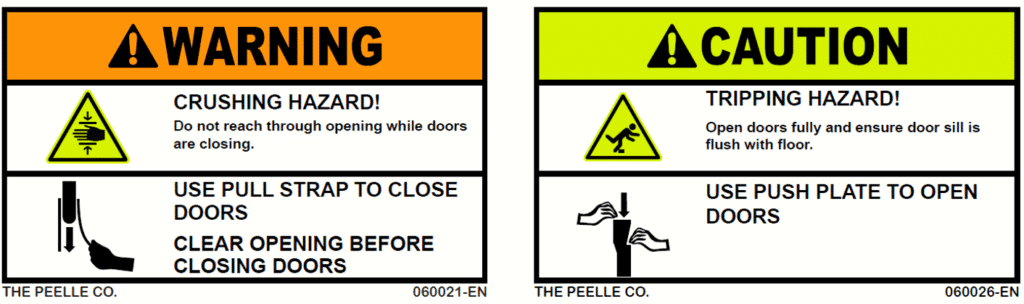

- Because freight elevators with vertical sliding doors are not mainstream, which type of signage is available to the maintenance company to educate the end user and operator on proper operating procedures?

- In a post-COVID-19 world, which options are available for door panel design to mitigate the spread of germs and bacteria? How and by whom may these be cleaned and sanitized?

Get more of Elevator World. Sign up for our free e-newsletter.