Benefits of IoT Remote Lift Monitoring

Jul 1, 2021

DOPPLER solution keeps maintenance results accountable.

The extensive use of technology augments traditional maintenance, capturing data and insights that are not easily accessible with existing systems. The sensor-based maintenance includes common sensors that are being used in a way that upgrades the effectiveness of elevator maintenance.

DOPPLER’s clients benefit from the Internet of Things (IoT) Remote Lift Monitoring Solution (RLMS), which was recognized in the Greek “Health and Safety Awards” in the category “Innovative Application of Systems or Technology for QHS.” This solution was developed by DOPPLER software engineers to facilitate the processes and generate accountable results. It targets elevator installation and maintenance companies and facility-management companies, and is ideal for technicians, aftersales services and support teams.

Today’s Challenge: Existing Situation

Elevator service companies visit lift sites for both scheduled maintenance and unexpected malfunctions. The purpose of this first visit is to identify the situation and the elevator’s failures, so a second visit is, most of the time, requisite to solve the problem. Important factors to consider:

- Most elevator installation and maintenance companies have clients in many areas that may be geographically separated from one another.

- When the technician visits the lift site, he contacts either his own company team or the DOPPLER Aftersales Department, sometimes struggling to describe the situation he has to deal with and recognize the fault information, via photos/videos and/or phone communication.

- All of the above factors cause an expanded danger due to the multiple exposure at the premises, and require increased resources — time and cost — which are charged to the company and its clients.

At the same time, the COVID-19 pandemic has had an important impact on our personal and business/professional lives and has brought up the necessity of surface-contact avoidance. In an elevator, the landing and car operating panels are common surfaces that are being used by numerous passengers and tenants every day.

Technology Used: How It Works

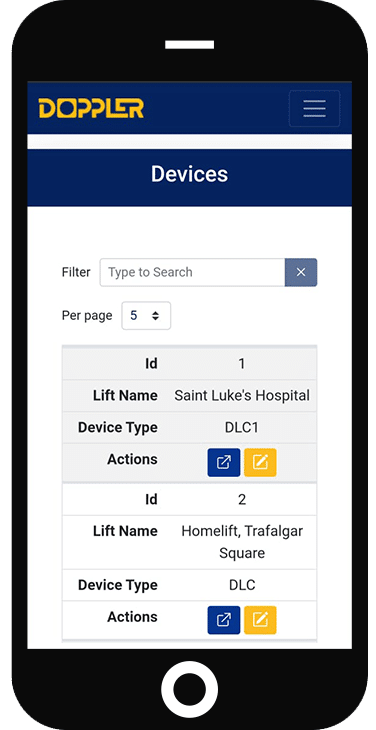

Guided by these market needs, DOPPLER developed the IoT RLMS, a device that offers the following capabilities:

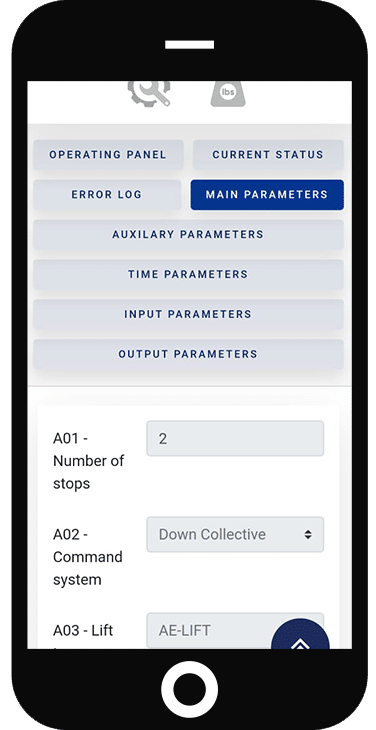

- Communication with the elevator board through RS232, enabling continuous extraction of information relevant to the actual operation status and scheduled parameters

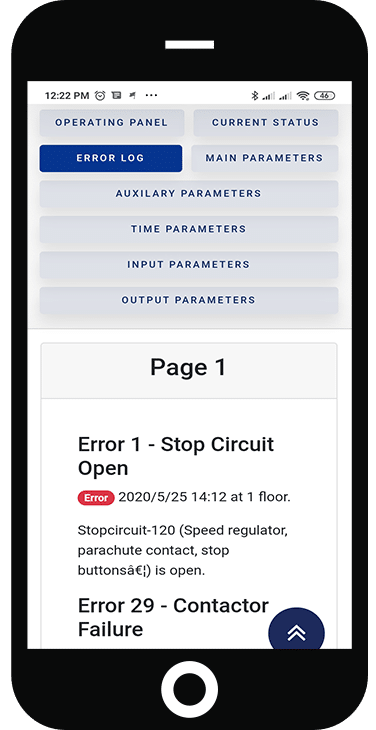

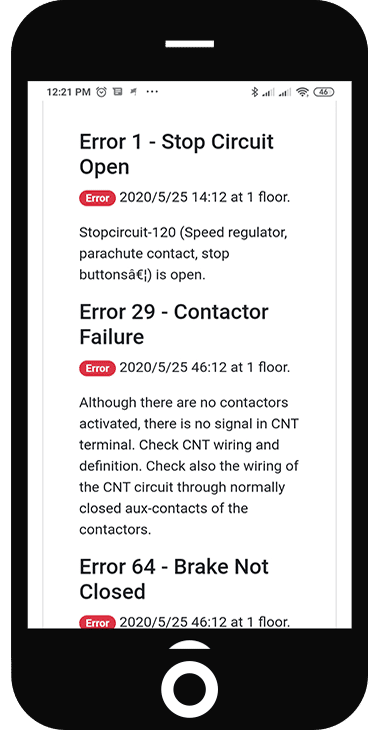

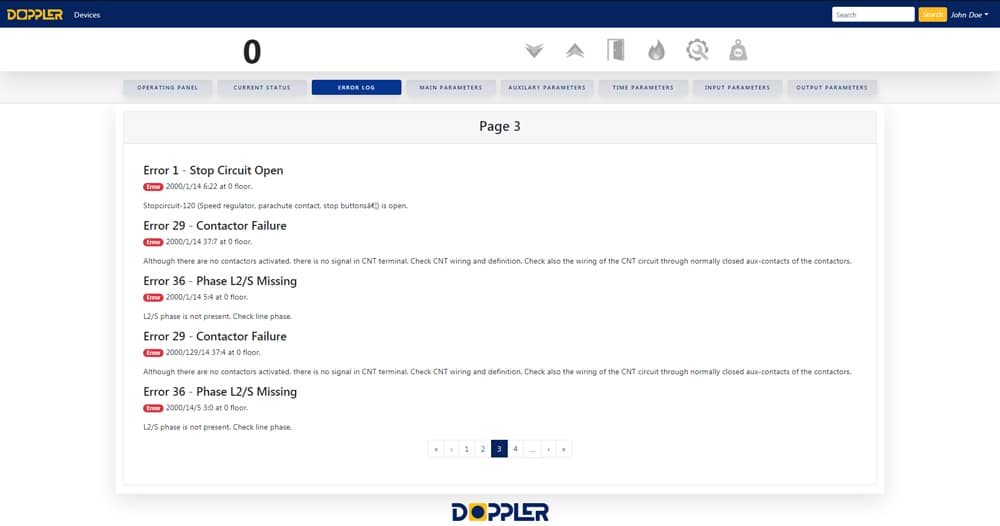

- Collecting and forwarding the board data to a laptop, tablet or mobile phone in real time

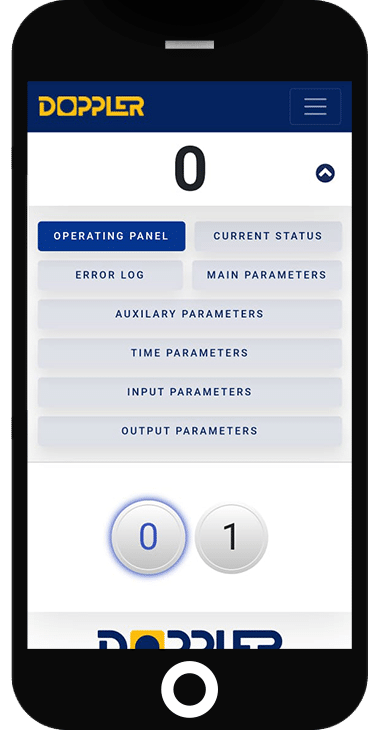

The IoT RLMS is an electronic device installed on the elevator board, allowing remote monitoring of the elevator via serial communication. The communication is being established by GSM, Wi-Fi or ethernet and is insured with safety certificates.

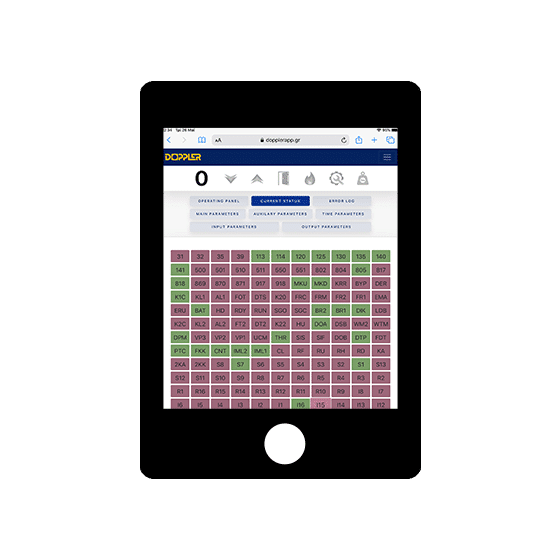

The monitoring is being completed by web software that was developed by DOPPLER software engineers especially for this reason. Whenever a fault occurs, the device sends a signal to the software application, and a notification with additional details is visualized on the screen.

Installation Options

The Remote Lift Monitoring Device can be used in the following ways:

- As an aftersales service tool, the device is being installed by the technician when he visits the lift, enabling direct communication with the DOPPLER Aftersales Department in a faster and more accurate way. In this scenario, the IoT device is not permanently installed on the board, but placed just for a limited time.

- As a permanent monitoring device, it is installed on the elevator board allowing a continuous connection with the control center of the installation company or the facility manager of the building. In this case, the control center communicates directly with the elevator and monitors its operation status and/or any occurring faults.

- As a monitoring device in connection with DOPPLER’s cloud service center, it is permanently installed on the elevator board. In this case, both the control center of the installation company and the DOPPLER Aftersales Service Department have a continuous and direct communication with the elevator, monitoring its operation status and any faults. When required, the DOPPLER Aftersales Department offers consulting services. Additionally, DOPPLER monitoring software retains statistical data of the operation, facilitating creation of an effective maintenance plan. These data can also indicate replacement of spare parts that have exceeded their usage limit.

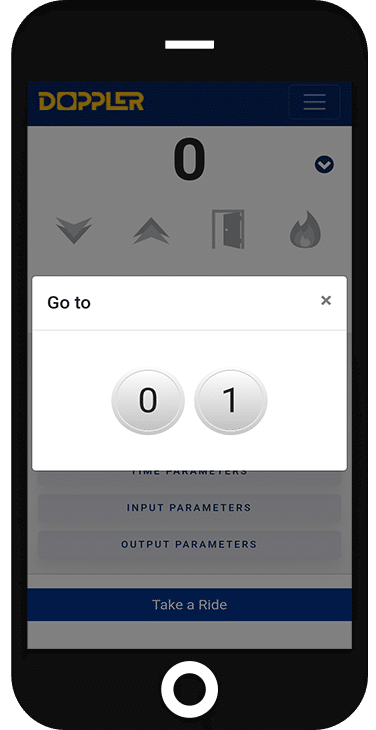

- Communication with the elevator through a mobile phone connected to the dedicated DOPPLER app. In this case, the user can see the COP in his screen, watch the operation status and call the elevator remotely. This feature can be offered to building tenants who use the elevator as a hygiene solution, so they could avoid any surface contact in the lift.

Benefits for Stakeholders

With the IoT RLMS, benefits for the installation and maintenance company are significant:

- It helps reduce required lift visits since it eliminates the need of an identification visit.

- It reduces the visit time since the technician can now be well prepared to solve the problem prior to the visit at the premises.

- It offers an upgraded communication with the DOPPLER Aftersales Department, as both companies can see the application’s screen and identify the same problem.

- It contributes to maintenance transparency.

- It offers valid data for operational planning and decision-making procedures.

- It allows remote calling of the lift.

- It is a customized solution, offering ongoing development.

Building owners and managers could also benefit from using the RLMS:

- Immediate access to information and data

- Real-time monitoring of all equipment status across sites

- Alignment of the costs with their customers’ needs and their business plans

- Improvement of the passenger experience with reduced unplanned elevator downtime

- Improved business efficiency

- Savings generation and reduced overheads

- Consequently, the RLMS boosts a company’s productivity and efficiency, increases the safety and the availability of the lift and upgrades the tenant experience.

Conclusion: What’s Next?

The elevator maintenance industry is changing dynamics, and IoT technology is gaining ground day by day. Their combination offers significant advantages over traditional methods. Using IoT technology in a human-centric way is DOPPLER’s priority and motivation for ongoing development.

Get more of Elevator World. Sign up for our free e-newsletter.