China Shining

May 1, 2016

Despite slower growth, the world’s largest vertical-transportation market is still a land of opportunity.

Rapid urbanization created explosive growth for the vertical-transportation market in China in 2003-2013. Although that growth is slower now, with the new-equipment market declining approximately 5% in 2015, the market remains the world’s largest for the elevator/escalator industry. Most of the large OEMs are expecting another 5% decline in new-equipment sales in 2016, followed by stabilization in 2017. Major players continue to invest in infrastructure and personnel, and a new law promises to thin the herd of maintenance providers and give more business to the big OEMs.

Besides growth for the big players, the new regulations, part of the Law on Safety of Special Equipment, which went into effect on January 1, 2014, also promise to improve safety in China, which has seen its share of horrific accidents over the past several years. The new law holds property managers responsible for monitoring and fixing elevator problems. Going forward, property managers are more likely to turn to the OEMs or their subsidiaries for this work, rather than going with cheaper alternatives that could result in legal penalties or, even worse, accidents.

China’s maintenance-market outlook is strong, thanks to these changes. Lagging elevator intensity (number of elevators per square foot of new construction) compared with that of other parts of the world looks to keep new-equipment demand brisk.[1]

Daniel Safarik has lived in Shanghai for approximately a year as director of the Council on Tall Buildings and Urban Habitat’s (CTBUH) China Office and observes that, although people are less “spendy and extravagant” these days, China remains an exciting, dynamic market. He opines:

“Speaking generally about the tall-building market, if you take a look at the CTBUH Year in Review 2015, it is clear there is still a lot of building going on. China leads the world in terms of tall buildings, completing 62 of the 106 buildings of 200 m or taller in 2015 and marking another record number of completions (100) of supertalls (buildings taller than 300 m).

“Anecdotally, one hears negative reflections on the overall economy and the impact it will have on the [tall-building] industry, but you have to remember what we are comparing China’s economy to. In the sense of the world economy and the tall-building industry, ‘slowing down’ in China still looks pretty fast compared to everywhere else in the world.”

China has an installed base of approximately 4.67 million elevators and escalators, or approximately 23% of the global total. Rapid tall-building growth over the past decade laid the groundwork for a healthy maintenance-market outlook, which grew by 18% in 2014, 15.3 % in 2015 and an estimated 12.7% in 2016. By 2020, China is expected to be home to 40% of the world’s installed base.[1]

New-equipment orders in China have been dropping, but not precipitously, going from 63.1% (562,350 of 890,350) of the world market in 2014 to 61% (539,856 of 884,016) in 2015 to a projected 58.5% (512,863 of 876,055) in 2016.[1]

Industry Makeup

Nearly half of the vertical-transportation industry in China is controlled by big international players, such as Otis, KONE, Mitsubishi Electric and Hitachi Elevator. Another 25% consists of other large international and domestic players, such as Canny Elevator, SJEC Corp. and Shenyang Brilliant Elevator Co., Ltd., along with thyssenkrupp and Schindler. The remaining 25% is made up of more than 400-plus smaller companies.[1]

The service and maintenance industry is highly fragmented, highly populated (by more than 5,000 registered companies) and, until now, poorly regulated. The new safety law requires OEMs or entities commissioned by them to perform post-installation alteration or repair.[1] In response, OEMs are ramping up employment in China. Otis tells ELEVATOR WORLD it plans to add 1,000-1,500 mechanics each year for the next several years to support its growing maintenance network.

OEMs stress the importance of having large local footprints and back up such statements with action. Thomas Oetterli, at the time Schindler China CEO, went so far as to joke in summer 2015 that “it is a mistake that I’m here [in China],”[2] implying the position should belong to a Chinese person. Oetterli has since been named Schindler CEO. Daryoush Ziai, formerly Head of China Field Operations, succeeded him as of April 2016. In 2014, Schindler doubled its presence from the previous year, going from 100 to 200 offices. KONE has more than 500 locations; Otis has 300 and thyssenkrupp has 200.[1]

The past several years have seen companies making significant investments in R&D, testing and manufacturing in China. Safarik says he came away impressed by a visit to KONE’s 235-m-tall, 36-story test tower that opened in December 2015 adjacent to its engineering and R&D facility in Kunshan (EW, February 2016). He observes, “It’s quite an impressive building on its own and is connected to a very well-organized, clean factory that not only produces, but designs and tests, elevator components.”

Other recent physical expansions include:

- Formally welcomed on March 23, thyssenkrupp’s new 15,000-m2, 40-m-tall multipurpose facility in Shanghai, which brings project management, product development, manufacturing and training together under one roof. The facility also holds a multimedia showroom, the first of its kind for thyssenkrupp, which provides visitors an interactive, 360° look at the company’s latest innovations.

- thyssenkrupp’s 100,000-m2, Zhongshan Elevator Plant that includes a 248-m-tall test tower, under construction in Zhongshan.

- 120- and 100-m-tall test towers in Chengdu and Zhongshan, respectively, for which ground was broken by Canny Elevator subsidiaries in November 2015, and the addition of a 288-m-tall test tower to Canny’s existing 95-m-tall tower at its headquarters in Suzhou. The new tower topped out in November 2015.

- A new Schindler manufacturing facility in Shanghai’s Jiading Industrial Zone, which opened in May 2014 (EW, August 2014)

- A Mitsubishi Electric US$6.5-million, 6,400-m2 elevator equipment factory in Shanghai, which opened in July 2014, part of a larger US$21-million plan to add another 25,000-m2 factory, development/engineering center and test tower in an effort to double capacity to 20,000 units per year (EW, November 2014)

- A Wittur components factory in Suzhou, which was welcomed in May 2013, designed to be flexible in terms of design options, as well as environmentally sustainable. Wittur Elevator Components (Suzhou) Co., Ltd. Managing Director Li Shaohua proclaimed the factory “a big success” (EW, September 2014).

Big Cities, Big Technology

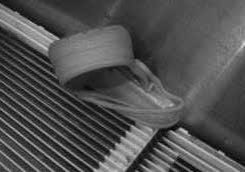

China has 14 cities with populations in excess of 5 million, including Shanghai with 22 million people.[3] It is here that companies debut their most impressive innovations, such as Mitsubishi Electric’s first-in-the-world spiral escalator in the Daimaru department store. Safarik says that throughout China, there are considerably more energy-efficient features, such as escalators outfitted with sensors that make them shut off when no one is using them, than there are in the U.S.

Growth has slowed in major urban centers such as Shanghai, Safarik observes, but second- and third-tier cities in the Chinese interior are seeing a frenzy of construction activity. There are many wealthy provinces that have dense populations and not enough elevators to serve them. China’s average elevator/escalator density (number of units per 1,000 people) is 2.2, compared with 6 in Japan and 4 in Russia.[1]

In some cases, developers in China have been overly optimistic, as evidenced by eerie photo essays and stories one sees about China’s “ghost cities.”[4] And, Safarik notes, questions swirl in Western media about the veracity of China’s official numbers.

Those in business in China acknowledge the market has matured following the decade of dizzying growth. From late 2014 to early 2015, the Chinese economy entered a “new normal” as a result of a lackluster property sector, says Perry Zheng, president of Otis China. “The changing market landscape has posed challenges to many industries, and the elevator industry is no exception,” he states.

Still, Otis continues to win major jobs. The company announced numerous significant infrastructure contracts recently, including one to supply nearly 400 escalators to 39 stations within Tianjin Metro Line 6. It also secured significant metro work in Chengdu, Wuhan, Changsha, Shanghai, Kunming and Shenzhen, to name a few.

Otis’ notable high-rise work includes the 660-m-tall PingAn Finance Center in Shenzhen, China’s new tallest building, and the under-construction Dongguan Huijing Hilton Hotel in Guangdong, China, which will be the largest hotel in Asia (in terms of number of guest rooms). Otis equipment is also going into the:

- 290-m-tall Nanjing International Commerce Center

- New Bund World Trade Center, a multiple-tower development that will form a new business district in Shanghai

- Guiyang Huanguoyuann, a 347-m-tall twin-tower complex that will be the tallest in western China

Oetterli said that Schindler’s sales and profits in China are growing faster than the Chinese economy and its appetite for further growth is strong. He projects Schindler employment in China to double from approximately 10,000 currently to 20,000 in the next several years.[2]

The Chinese market is very different from that of other parts of the world, Oetterli noted. Typically, half of sales are generated by new equipment and half by maintenance/modernization. In China, new equipment has accounted for more than 90% of Schindler’s sales thus far. “China is our biggest market and accounts for two-thirds of our total business,”[2] Oetterli added.

Schindler China’s R&D center in Shanghai rivals that of its Switzerland headquarters, Oetterli noted, and the balance could very well shift even further soon: earlier in 2016, Schindler announced plans to downsize staff at its headquarters in Switzerland from 200 to 80 by the end of 2017 as its focus shifts to Asia (EW, May 2016).

Overall, companies’ faith in China remains strong. Upon opening its new Shanghai multipurpose facility in March, thyssenkrupp stated:

“For the past two decades, thyssenkrupp has spared no effort in keeping its promise to China, developing together with the country by implementing its far-sighted strategy, gradually increasing its investment in the country, and carrying out various R&D projects. Additional innovations and technologies will be introduced into China to support urbanization.”

thyssenkrupp Elevator AG Chairman of the Executive Board Andreas Schierenbeck reiterated the importance of the new Shanghai facility:

“Merging our expertise and wealth of global experience with the immense local talent here in China, I am certain that this facility will secure a top spot on thyssenkrupp Elevator’s global map.”

Acknowledgements

ELEVATOR WORLD extends special thanks to Credit Suisse analysts Andre Kukhnin and Tiantian Li, who provided many of the facts and figures used in this report in their Global Elevators & Escalators study, published in 2014 and updated in December 2015, and EW China Correspondent Peng Jie.

References

[1] Credit Suisse Equity Research, Global Elevators & Escalators, August 28, 2014.

[2] Wenqian, Zhu, “Chinese Market Lifts Schindler to Success,” China Daily USA, July 13, 2015.

[3] Wikipedia, “List of cities in China by population and built-up area” (en.wikipedia.org/wiki/List_of_cities_in_China_by_population_and_built-up_area).

[4] Raposa, Kenneth, “What Will Become of China’s Ghost Cities?” Forbes, July 20, 2015.

[5] CIA World Factbook (www.cia.gov/library/publications/the-world-factbook/geos/ch.html).

Get more of Elevator World. Sign up for our free e-newsletter.