Designed to Deliver

Jul 1, 2021

Your author showcases IMEM’s new factory and commitment to R&D.

by Antonio Pérez Luzuriaga

IMEM is a company focused on the design, manufacturing, installation and maintenance of lifts since 1968, thus accumulating 53 years of experience in the lift sector. Family-owned and operated, it is one of the top ten lift companies in Spain. In addition, the company is one of the most active manufacturers in the European market. Its lifts are installed in more than 65 countries across five continents, transporting hundreds of thousands of people each day.

The company’s customers and collaborators include fellow lift companies of all sizes and their specialists, among other professional clients for whom they provide vertical transportation solutions, with an emphasis on engineering and technological innovation. With their accumulated knowledge, track record, technological expertise and experienced personnel, IMEM is confident it can always provide useful advice, lift design and manufacturing services, no matter how demanding or complex a project.

IMEM provides in-house design and manufacture of lift systems, with direct hands-on management of the value chain from start to finish. That means, according to the company, it controls the quality and lifecycle of their products in all stages and can offer customers fully comprehensive technical support.

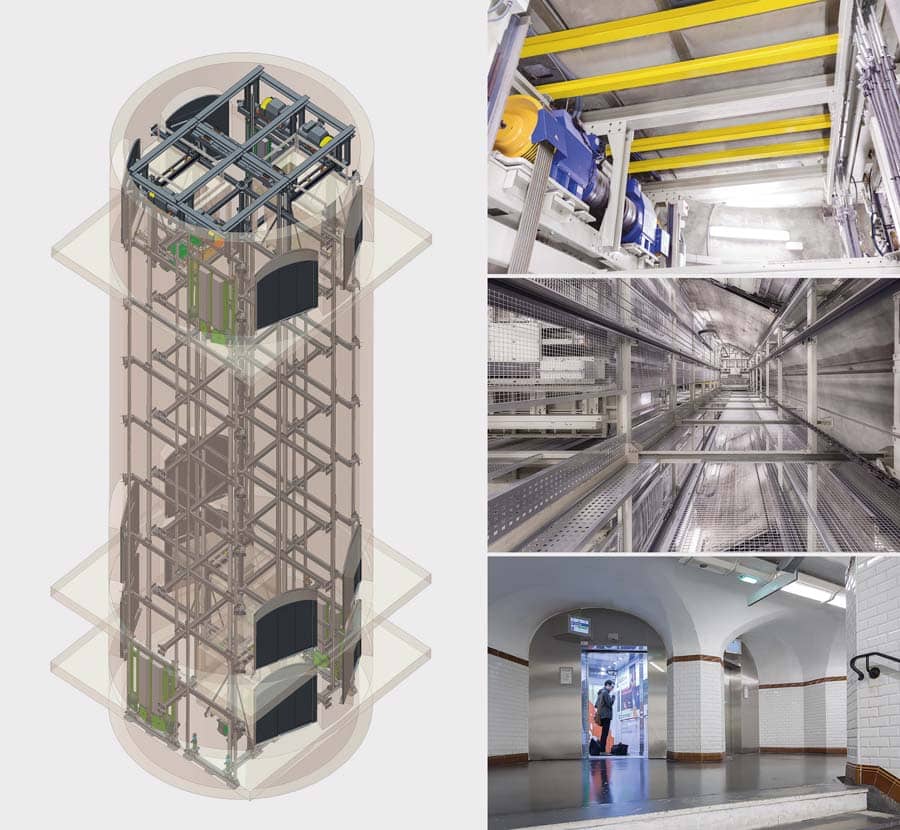

The New IMEM Lift Factory

In February 2020, IMEM completed its new factory in Santander, Spain, after more than two years of civil works. In 2014, IMEM undertook the first phase of this project by automating its original mechanical production plant, which positioned its factories among the most modern in Europe. This second phase involved construction of an electrical production plant attached to the mechanical plant, a new office building, renovation of the original offices, a new product showroom and thousands of m2 of warehouse space, as well as amenities such as parking facilities, dining rooms and gardens.

IMEM’s goal was to create a “state-of-the-art” work environment equipped with the latest technology for the design and manufacture of lifts, a friendly and warm environment for company employees and, above all, a memorable experience for all customers, suppliers and friends who visit.

Firm Steps For a Technological Leap Forward

IMEM has never been characterized by its comfort zone. In 1997, when the market was still focused on solutions from older technologies, IMEM became the second European company to develop a machine-room-less lift with a gearless permanent magnet traction machine. This made the company a leading manufacturer in this field.

Currently, IMEM has once again sought technological disruption in the elevator market, offering a world premiere of a new generation of lifts under the Silens Pro Revolution® brand. Although the company feels there are numerous technical and commercial advantages to this new range of lifts, most importantly, the brand introduces a significant change in concept. To illustrate this, IMEM offers the automotive industry as a comparable example.

A vehicle is no longer a mix of independently working components. It is a system that manages and has information about every movement, a mix of parts capable of driving itself even without oil because it is an intelligent system. Similarly, the Silens Pro Revolution is a fully intelligent, interconnected system. This not only refers to full integration, but each unit being based on a learning machine concept, thus able to learn from the traffic algorithms to improve the passenger experience.

Through the introduction of Programmable Electronic Systems in Safety Related Applications for Lifts (PESSRAL) devices, the Silens Pro Revolution lift range increases reliability and reduces production, installation, commissioning and maintenance costs, while increasing safety standards both for passengers and maintenance personnel. This way, the Silens Pro Revolution is a self-learning lift that eases commissioning by not requiring an installation engineer to be inside the shaft or on the car roof due to new shaft intelligent revolutionary elevator system (SIRES) technology.

AI is becoming more present in our daily lives: More and more devices interact with all of us while gathering data that is then used to make decisions. The Revolution range is able to gather data directly from the information in the system to make decisions. In addition to those already described, Silens Pro Revolution offers an array of advantages too broad to be fully explored in this article, but IMEM highlights its effort to design an elevator capable of increasing its nominal speed by 20% during the entire travel curve without increasing the nominal power rating of the gearless machine, thus achieving a faster lift able to reduce waiting times with greater energy efficiency and maximization of available space.

Get more of Elevator World. Sign up for our free e-newsletter.