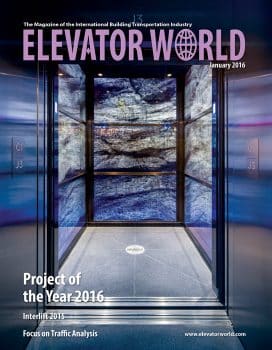

Elevator Modernization at Great Eagle Centre

Jan 1, 2016

Safety, ride comfort, performance, passenger experience and energy efficiency are brought up to the latest standards.

Hong Kong, China

submitted by Sherring Mak, Jardine Schindler Hong Kong

The 33-story Great Eagle Centre is an iconic office and retail building strategically located in the prime commercial district of Wan Chai, adjacent to the famous Hong Kong Convention & Exhibition Centre. Completed in 1983, the 146-m-tall building is owned and managed by the 40-plus-year-old Great Eagle Holdings Ltd., one of Hong Kong’s leading developers. The group’s corporate headquarters occupy the upper floors of the building.

Great Eagle had very specific targets in mind: to bring the building’s 32-year-old elevator system up to the latest standards of safety, ride comfort, performance, passenger experience and energy efficiency. The modernization work started in October 2013 and was completed in May 2015. Schindler Hong Kong modernized 14 elevators (12 passenger elevators and two service elevators) operating at speeds of up to 8 mps across three elevator zones.

Special Challenges

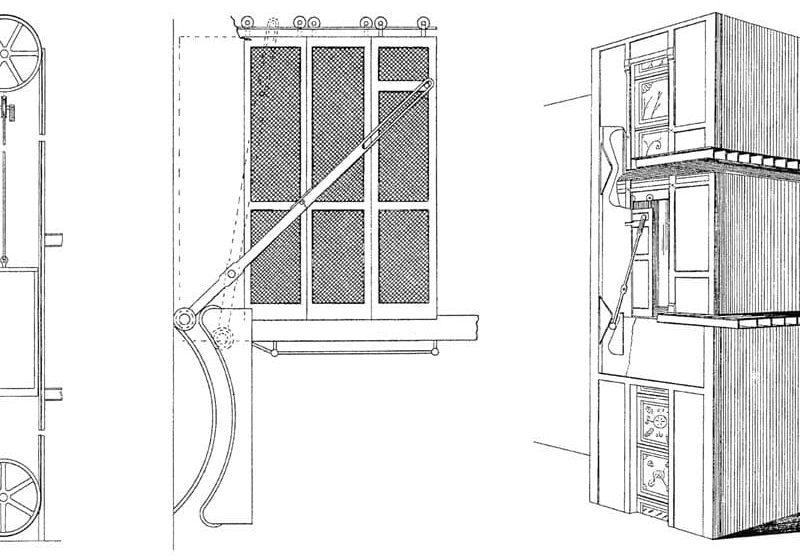

Schindler’s key challenge was to fit the elevators of this highly populated (more than 1,500) building with new elevator controllers, regenerative drives featuring Power Factor One (PF1) converters, an intelligent traffic-dispatch system, gearless machines and new door drives. The narrow access route to the machine room meant machines had to be dismantled for transportation and later reassembled in the machine room.

Change of Passengers’ Habits

The change from a conventional elevator system to a transit-management (or destination-control) system means a change in daily habits for the building’s tenants. The way the new elevator system worked had to be clearly communicated to them. Meetings were held with tenants a month before the changeover, a leaflet that showed how to use the new transit-management system was distributed, and an app for smartphones with the same purpose was deployed. The weekend before the changeover, the Schindler modernization project team conducted a series of tests to ensure the transition would be smooth and seamless.

Narrow Access to Machine Room

The challenge was that the route to the machine room was very narrow. This resulted in the need to dismantle the machines for transportation, then reassemble them in the machine room. The equipment had to be broken down into pieces and carried into the room. Schindler’s modular modernization method enabled it to solve this problem.

Modernization Scope and Results

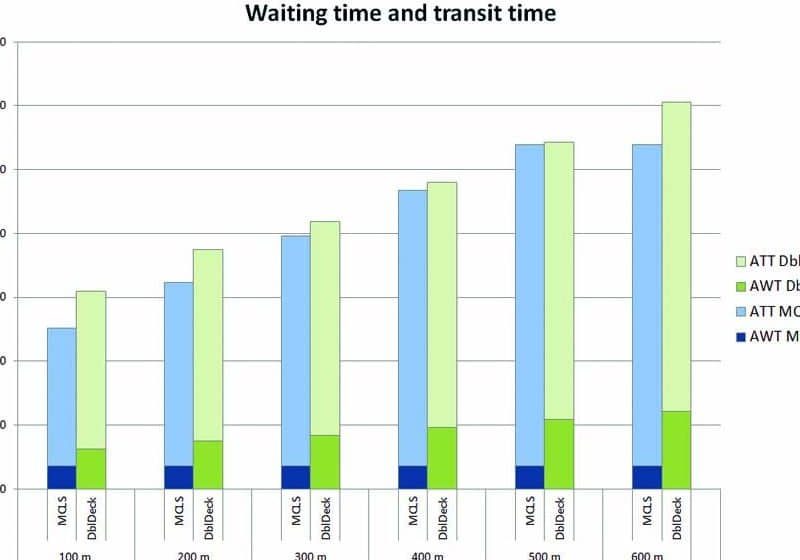

The project improved traffic performance thanks to the implementation of Schindler’s Personal Occupant Requirement Terminal (PORT) technology, which not only cut waiting times and destination times, but also brought numerous energy-saving and security features. PORT, powered by a sophisticated algorithm that manages the complexities of traffic patterns as they change throughout the day, notably groups passengers going to the same floors to ensure they are taken to their destinations in the shortest time possible. In Great Eagle, PORT decreased the average destination arrival time by approximately 10%. Meanwhile, Schindler’s latest elevator controls replaced the old Aconic elevator control system, resulting in improved elevator performance, ride comfort and reliability.

Schindler’s PF1 drives met the client’s requirement for an energy-efficient system. The regenerative devices enable energy regenerated by the elevators to be fed back to the building’s electricity grid, resulting in energy savings of approximately 35%. Great Eagle had also decided to replace the motor-generator sets with gearless machines to obtain the optimum combination of efficiency and energy regeneration. Safety features complying with the latest Hong Kong standards were incorporated, including ascending car overspeed protection and unintended-car-movement protection devices.

A newly equipped load-measuring device, the Distribution Management System, now guarantees smooth starts and stops. This device automatically recognizes the number of passengers in a car so the optimum motor speed can be applied during starts and stops. The car-doors drive was also replaced to achieve shorter opening and closing times and improved performance.

To minimize disturbance to the tenants, the elevators were modernized one at a time over an average period of 12 weeks each so that their overall operation was unaffected. In addition, Schindler was requested to build two additional sets of landing openings on the top floor. Strict time limitations imposed on the project execution, such as only allowing noisy work on Saturday afternoons and Sundays, made careful planning and frequent communication with the client essential to ensure that the modernization process was carried out smoothly. The project was completed in May 2015 with minimal disturbance to the building’s tenants and to the full satisfaction of the customer.

Why Modernize?

In a city crowded with high-rise commercial and residential buildings such as Hong Kong, buildings account for approximately 90% of total electricity consumption, while elevators and escalators account for 10-15% of each building’s total energy consumption. This makes enhancement of energy efficiency in buildings one of the quickest, cheapest and cleanest ways to address energy and environmental challenges. Modernization of elevators in older buildings is an investment in a sustainable future, since it can substantially reduce their environmental impact by decreasing their power consumption.

Credits

- Building developer: Great Eagle Holdings Ltd., Sino Land and Sun Hung Kai Properties

- Building owner: Great Eagle Holdings

- Building architect: Paliburg Development Consultants

- Transportation systems contractor: Schindler Lifts (Hong Kong) Ltd.

- Equipment manufacturer: Schindler Lifts (Hong Kong)

- Component supplier: Schindler Lifts (Hong Kong)

- Project consultants: Great Eagle Development and Project Management Ltd.

Also read: Elevator Modernization: When Is It Time?

Get more of Elevator World. Sign up for our free e-newsletter.