iwalk – The Newest Moving Walk by ThyssenKrupp Elevator

Jun 1, 2011

ThyssenKrupp Elevadores of Brazil recently launched the iwalk, an innovative moving walk, in São Paulo Metro.

The São Paulo Metro is the stage where the iwalk, an innovative moving walk, was recently launched by ThyssenKrupp Elevadores of Brazil. This new means of transportation was conceived and built in Spain as a solution to facilitate the assembly, transportation and installation of conventional moving walks. It is a green model that follows a sustainable concept and adds passenger comfort. Six iwalk units were installed to link two São Paulo metro stations, ultimately improving the travel of thousands of subway users in the congested metropolis.

Within the framework of the city’s metro expansion, ThyssenKrupp Elevator added the iwalk to its escalators and elevators to contribute to the swift movement of passengers (ELEVATOR WORLD, August 2008). Your reporter got a firsthand experience riding the iwalks during a recent visit to the new stations, which also feature glass gates on the platform edges: a shiny transparent tunnel that protects riders during the arrival of driverless trains.

Technological/Green Solution

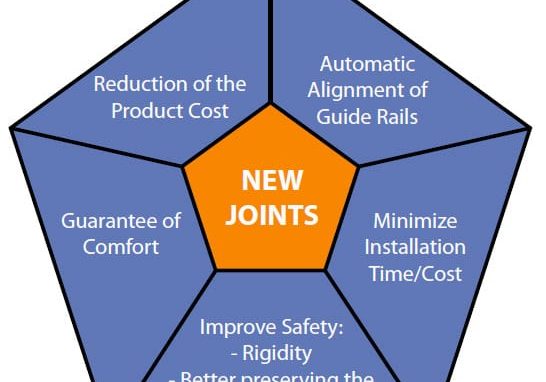

The iwalk is a global novelty that offers solutions for heavy-duty transportation systems. It features techno -logical developments and bears a green “i” in its name to indicate its sustainable principles.

The new equipment was installed in the metro to link two stations – Consolação in Green Line 2 and Paulista in Yellow Line 4.

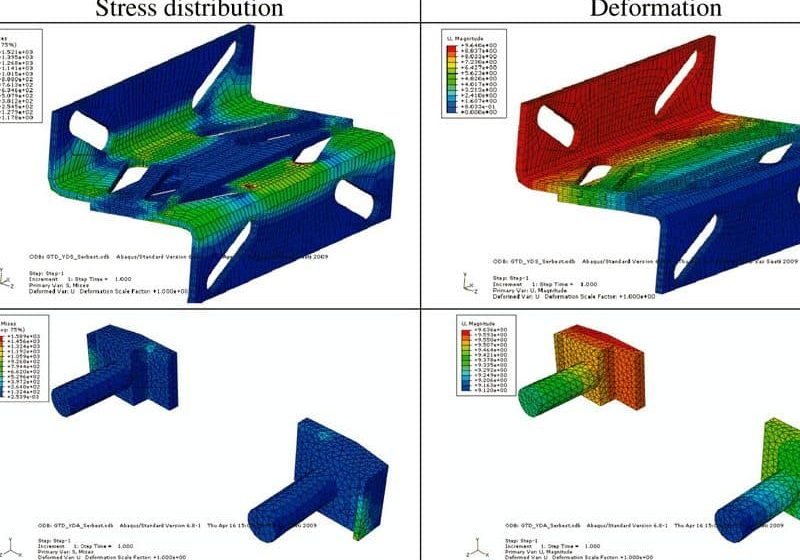

There are six heavy-duty moving walks located at the end of the platform at the Consolação station. They run along a 120-m tunnel to reach the top of the escalators that will take the passengers in both directions to the recently opened Paulista station. The original moving walk is equipped with new improvements. The comb plate height has been significantly reduced to 7 mm (compared to the 40 mm of standard models). This provides an easier walk on its surface and a safer passage between the fixed and mobile sections of the equipment for passengers pulling wheeled items over the combs. The iwalk claims to be the only moving walk that offers this characteristic on the international market.

The iwalk was designed to be environmentally friendly. Its driving system minimizes lubrication by oil drops (the pallets do not need lubrication) and reduces the number of components, as well as the power consumption of the machine. The moving walk remains in standby position when not in use. With ThyssenKrupp Energy Control intelligent technology, the speed increases gradually only when the rider treads on the iwalk. This system is also used in conventional moving walks supplied by the company.

Easy Installation/Flexible Transportation

Another convenient characteristic of the iwalk is the system’s division into modules, which makes manufacture and installation easier and more flexible. The reduced number of components includes transportation advantages and facilitates assembly at the jobsite. As a compact product, it can be transported in containers sparing some of the room usually needed to store regular moving-walk components at building sites. With this new concept, it is possible to install moving walks where they were once unfeasible. Moreover, the fewer components used, the faster the assembly. The practice of complete assembly in the factory has been replaced by a serial production of the central sections that are assembled to the entrance and exit platforms at the jobsite.

The iwalk does not require a special structure, since it can be installed on existing floors. This is possible because it is self-contained in its own guide rails where the palettes run, avoiding costly guide-rail adjustments that are necessary in traditional installations. This moving walk requires only a 380-mm-deep pit, whereas the conventional models need an approximately 1.15-m-deep pit.

Attractive Design/Added Comfort

The design of the iwalk had to be in accordance with the simple, yet elegant architectural trends of today. With this aim, the balustrades and handrails follow curving lines with no edges, complemented with the use of glass panels rendering a slim, transparent and light structure. The installation of a moving walk to connect two stations intends to provide the subway users with a faster and more comfortable passage through the tunnel. At a speed of 0.65 mps, it takes 3 minutes to reach the opposite end.

The comb plate design facilitates improved accessibility for those using wheelchairs or similar wheeled items.

Traveling in the São Paulo Metro Network

In 2008, your reporter discussed the overall figures regarding the extension and modernization program by the Companhia do Metropolitano de São Paulo that involved an estimated investment of BRL21 billion (US$12.3 billion). During this visit, ThyssenKrupp Elevadores and the metro company’s representatives accompanied your reporter on a ride from the new Faria Lima to Paulista metro stations, both located in Yellow Line 4. This is among the first lines in Latin America to feature glass partitions to separate the platforms from the rails in all the stations. The gates open with those of the trains, avoiding accidents and other operating complications. The illumination system is efficient with electronic reactors, high-performance reflectors and fluorescent lamps.

The Faria Lima station is equipped with four stainless-steel ThyssenKrupp machine-room-less (MRL) elevators for accessibility and 10 escalators. Your reporter observed how the metro employees were trained on the use of the elevators so that they could instruct passengers with special needs. The recently opened station uses new driver-less trains manufactured by Hyundai in South Korea. Their automatic operation is safer, and the speed is always kept within the permitted ranges according to need. The trains are not divided into separate wagons; they are a long, articulated corridor so that passengers can circulate freely between the sections. Passengers have a full view of the whole train and can see it traveling into the tunnels.

Once the group and your reporter arrived at Paulista station, we went up the escalators, then directly onto the iwalks that took us along the passageway to flow into Consolação station. In Paulista station, in addition to the six connecting iwalks, there are six panoramic elevators and 18 escalators (also supplied and installed by ThyssenKrupp Elevadores).

ViaQuatro is responsible for the operation and maintenance of Line 4. This private/public partnership will invest more than US$2 billion in the line. When it is finished, it will cover 12.8 km with 11 stations.

Acknowledgments: Journalist Isabel Munhoz Silvares and photographer Dario de Freitas.

Get more of Elevator World. Sign up for our free e-newsletter.