Lubrication Innovation

Dec 1, 2020

In this Product Spotlight, your author discusses an automated system that saves time and money.

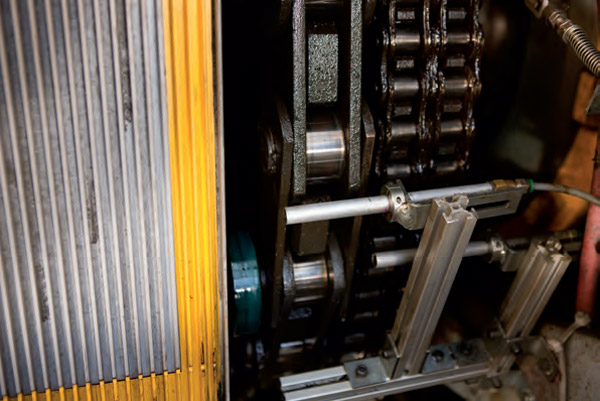

In recent years, technologies have emerged that have had a favorable impact on escalator maintenance, lowering both the costs involved and the burden on busy maintenance teams. One of these innovations is automated lubrication. In many high-traffic environments, escalators operate all day, every day, sometimes fully exposed to the elements. Central to the escalators’ motion is the step chain, and engineers and technicians are challenged with ensuring these chains receive adequate care and maintenance — often in tight windows — to maximize in-service time and minimize replacement costs. Replacing step chains can lead to extended downtime, depending on the availability of parts and labor.

Regular lubrication is a critical aspect of preventive maintenance, as this helps to keep the chain running smoothly and quietly, while greatly increasing the intervals between replacements. Conventional manual application requires the technician to take the escalator out of service, climb into the pit with a garden-style sprayer, then run the chains to apply lubricant. As an alternative, automated lubrication allows the escalator to remain in service, while lubricant is applied to the chain in a designed application, reducing the mechanic’s time in the pit, which contributes to safety.

The most common automated lubrication systems, which are often factory installed, have small reservoirs and brush systems that apply traditional mineral oil lubricants to the entire length of the chain. Chains, however, don’t wear evenly. In general, each link wears at its points of contact with adjoining links. This means that much of the lubricant in brush applicators is wasted on areas that don’t need protection. Additionally, mineral oil lubricants remain wet after application and can attract dirt and debris, which often accelerates breakdown of the lubricant and, ultimately, increases chain wear through abrasive action in what is referred to as a lapping effect.

In 2015, Castrol LubeCon, based in White Cloud, Michigan, adapted an automated lubrication system to escalators from the company’s experience with industrial applications, including automotive plants and steel foundries. The system combines a larger (1.5-55-gal.) reservoir, a programmable controller with four independent channels and shot-to-point application of dry-film lubricant. The system was first tested successfully in challenging commuter transit environments and has since been adopted by major airports, retailers, universities and mixed-use complexes, with installations on more than 250 escalators and moving walks.

The lubricant is specialized, designed to be applied only to wear points on the chains (pins, bushings, etc.) where metal-to-metal contact is concentrated. Its fluid is a fast-penetrating carrier, delivering protective formula materials to target surfaces and evaporating, leaving the chain essentially dry. It doesn’t attract debris, so the chains stay clean after application. Targeting only chain wear points leads to less lubricant usage and waste disposal, creating a positive environmental impact, while saving time and money.

In 2016, the Castrol LubeCon automated system was trialed for just over 11 months on a busy transit center escalator in Washington, D.C. The extraordinary escalators there are some of the longest in North America, rising nine stories from the train platform to the street surface. Castrol and transit authority mechanics measured the chain at the beginning and end of the trial and determined that the 400-ft chain had only stretched by approximately 5/16 in. As a result, the life expectancy of the very expensive set of chains went from a few years to greater than 10 years.

Regular lubrication is a critical aspect of preventive maintenance, as this helps to keep the chain running smoothly and quietly, while greatly increasing the intervals between replacements.

Just as importantly, the out-of-service time for preventive lubrication maintenance was reduced, as routine maintenance requires only that mechanics do a quick visual check on the reservoirs, check the alignment of the lube heads and close the pit back. With the Castrol LubeCon automated system, these massive escalators now only consume a few pails of lubricant per year. (Smaller, retail-environment escalators consume less than a pail a year.)

On high-traffic escalators in challenging environments, preventive maintenance is critical. Given the demands these machines place on busy maintenance staff, robust, effective automated lubrication offers a clear advantage over conventional practices.

Get more of Elevator World. Sign up for our free e-newsletter.