Formula Systems’ 3D detection for elevator door protection offers new way of looking at safety.

by Cornelius Walls

This article was first presented at the 2019 International Elevator & Escalator Symposium in Istanbul. For more information on December 7-8, 2020’s event in Amsterdam and to participate, visit www.elevatorsymposium.org.

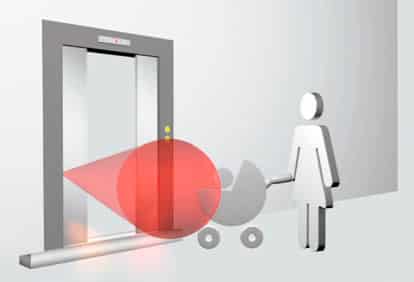

The main focus of this article is to give details on both current and upcoming code requirements and changes. Formula Systems’ Foresight 3D meets code and gives the industry a new way of looking at the safety of elevators. This technology focuses on 3D detection for elevator door protection using time of flight (ToF). This paper shows how it can be used to meet changes in the A17 code.

Current Door Protection Code: ASME 17.1

2.13.5: Reopening Device for Power-Operated Car Doors or Gates 2.13.5.1

Where required by 2.13.3.4 or 2.13.4, a power-operated car door shall be provided with a reopening device that will function to stop and reopen a car door and the adjacent landing door sufficiently to permit passenger transfer in the event the car door or gate is obstructed while closing. If the closing kinetic energy is reduced to 3.5 J (2.5 ft-lb) or less, the reopening device shall be permitted to be rendered inoperative. The reopening device used shall be effective for, substantially, the full vertical opening of the door (see 2.13.4.2).

The overall rationale for this code addition is that 80% of all incidents resulting in harm occur at the entrance. Of these, half are trip-and-fall; the other half is impact-by-doors. To eliminate as many of the door-impact incidents as possible, the ASME A17 Elevator and Escalator Standards Committee created an ad hoc committee to address the issue and provide proposals to improve safety.

2.13.5.3: Detection of Approaching Objects

The reopening device(s) shall be designed to detect one or more cylindrical target(s) approaching the entrance opening of the landing-side doors as required by 2.13.5.3.1. The cylindrical target(s) shall be oriented with the base parallel to the floor, with the height perpendicular to the floor and properties conforming to: a) diameter of 200 mm (8 in.), height of 1,000 mm (40 in.) and painted flat black per FED-STD-595C in the color range 37005-37050; b) diameter of 200 mm (8 in.), height of 1,000 mm (40 in.) and painted glossy white per FED-STD-595C in the color range from 17800 through 17999.

This target is a cylinder 200 mm (8 in.) in diameter and 1,000 mm (40 in.) tall. The illustration below shows three cylinders that simply represent three positions, where the one cylindrical target must be detected. This simulates a child approaching the detection zone.

Timeline for Code Changes

Code requirements of the 2019 edition of A17.1/B44 could come into effect as early as June. Adoption of the code is very often delayed, however — sometimes for years. Offsetting this delay is the tendency of the major companies to prefer to provide code compliance, regardless of the code adopted, to reduce risk. This means new elevator orders will likely be provided with 3D protection.

The existing technology allows for light curtains used as a door-mounted solution. This projects a 3D light into the hall about 18-24 in. into the walkway. This technology is very useful in places like hospitals and schools, where trip hazards are more common.

Formula Systems’ 3D Solution

Phase One: Door Mounting Solution Using Current Technology

- Each edge features 17 retroreflective sensor zones.

- There is continuous 3D protection from 25 mm to 1,785 mm.

- The 3D protection zone is 40° from the door axis (± 10°), protruding approximately 450 mm.

- Continuous 2D protection from 25 mm to 1,785 mm

- Maximum current consumption is less than 100 mA.

- Packaged in a 2,130-mm aluminum extrusion, which can be cut down to 1980 mm

- Full height protection where it’s required — along the leading edge of the landing doors

- Formula’s patented 47-beam 2D curtain included as standard

- Direct-to-operator (controllerless) connection capability (well-suited for OEM applications)

- Well-suited for refurbishment projects, using our standard universal interface

- Each door is independently protected, removing constraints with larger door openings.

- Edges automatically balance to compensate for changing ambient conditions.

- Designed for rapid installation

- Simple four-core cord capable of onsite adjustment and quick-fixing in case of damage

The Formula Systems 3D elevator-door light curtain offers a variety of innovative features designed to enhance the passenger experience, while reducing the potential for harm to both the individual and elevator. Some of these features include:

- 2D

- Sill Light, which utilizes high-contrast, low-level light sources to draw passenger attention to the floor sill zone, highlighting potential trip hazards.

- Beam Path Locator, a patented array of amber warning LEDs providing visual indication of the 2D beam path and confirmation of full system functionality.

- Adapt 3 “3D,” our 3D “adaptive” traffic-detection system, designed to enhance passenger comfort and protect doors from damage

Vision has been designed for direct connection to most current door-operator and controller designs. All it requires is a suitable low-voltage supply (18-30 VDC) with inputs switched to ground. Vision will also work with Formula Systems’ existing universal interface, and there will shortly be a new voltage- sensing Vision controller capable of managing all of Vision’s new features. This unit is driven by the latest 32-bit microcontroller devices, offering precise control and high system flexibility.

The Vision controller offers a variety of control options for each element, including changing light timings and determining various configurations for the two relay outputs. All features can be turned off, making the product a multifunctional unit to suit many elevator needs. In addition to the primary features of this product, Vision includes a simple “Eco-mode” function. This reduces power consumption by 30% when the elevator doors are closed.

Phase Two: Formula Systems’ ToF

A ToF camera is a range-imaging camera system that employs ToF techniques to resolve distance between the camera and subject for each point of the image by measuring the round-trip time of an artificial light signal provided by sensors.

Aiming to incorporate edge replacement and 3D into a single module, the 3D detection would be activated by a software switch. Thus, it becomes an option. The edge- replacement device would be either on the outside of the transom or hidden behind a glass window. Edges would no longer be necessary.

Data Analytics

Another feature of Vision, which goes beyond door protection, is that it will enable buildings to have a predictive- maintenance program. The unit will give the ability to assist in reducing normal wear-and-tear on the elevator doors. These features include:

- Predictive maintenance

- People counting

- Elevator optimization

- Automatic health checks

Summary

Formula Systems provides products with technology suitable for current code requirements. With future code modifications on the horizon, Formula Systems has taken an aggressive approach in identifying new technology to meet these changes. Aiming to incorporate edge replacement and 3D into a single module, this future technology will bring a new level of efficiency to elevator-door protection. Safety is always the ultimate concern. Understanding that, Formula Systems creates products with the aim to reduce the potential for harm to both the individual and elevator.

Get more of Elevator World. Sign up for our free e-newsletter.