A call for a central worldwide data pool with all VT incidents in the hands of an independent authority

by M.J. Mohamed Iqbal, EW Correspondent

This article was first presented at the 2019 International Elevator & Escalator Symposium in Las Vegas. For more information on December 6-7, 2021’s event in Amsterdam and to participate, visit www.elevatorsymposium.org.

The first hoist with a safety gear became an elevator — or, at least, the predecessor of the modern-day elevator. We have come a long way from those elementary beginnings. The more we progress, the better our deliverances on vertical-transportation (VT) systems should be.

What has evolved along with elevators is the element of risk they present. While the risks to the end users and the public have been well addressed, there remains the perpetual sword of Damocles hanging over the system’s dormant, but ever-present, danger lurking to be unleashed.

The statistics on this topic are largely vague and have not been collated or documented by any systematic authorities. One would only have to Google the term “elevator accident,” and the search results would show that we are yet to have a body or qualified institutional authority on such data.

Improvements and corrective and preventive actions depend on data, analysis research and actions recommended based on these studies. In the absence of a dependable authority to perform this activity, the onus of elevator safety lies with the individual manufacturers. This narrows the data and activity field of every manufacturer to the incidents relating to its own area of operation and products focusing on in-house issues, and the rectifications, analysis and results may not be passed on to the global elevator/escalator community.

We need to have a central data pool with all possible incidents recorded on a global level, and this, in turn, should be in the hands of an independent authority that is mandated, authorized and recognized worldwide. For example, the National Transportation Safety Board in the U.S. is well-relied-upon and is the go-to agency for any air-safety investigation. We need an equivalent of that in VT systems, the intent of which is to nudge the best minds in the field to think and act in terms of the safety of the end user, as well as the operator, technician or engineer who installs and maintains the elevator.

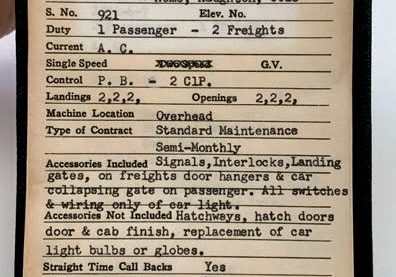

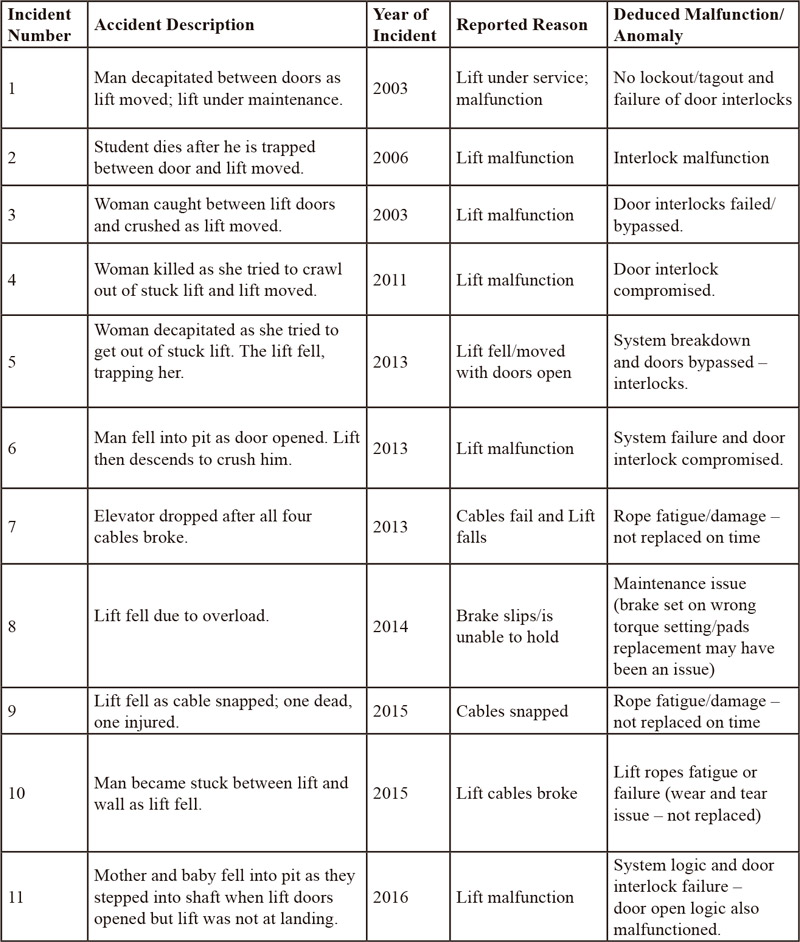

Many VT incidents also victimize the installers or maintainers. Let us consider a few accidents reported over the years to help show the repeated nature of elementary issues that lead to avoidable loss of life (Table 1). An analysis of these accidents shows the major reasons for them are:

- Freefall due to rope or cable breakage

- Unexpected movement out of control due to interlocks not in place

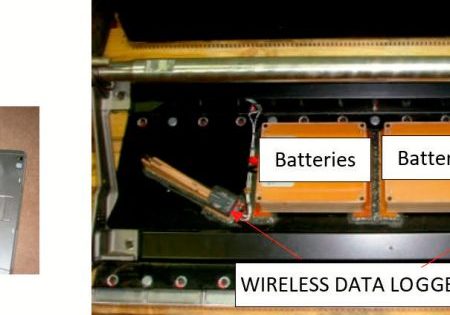

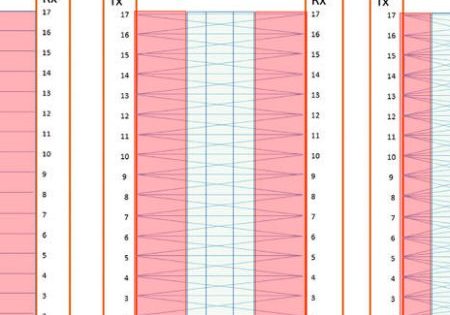

The major incidents that stand out are freefall and movement with the doors open — a direct pointer to either rope damage in case of freefall or a gate circuit malfunction, which is a basic interlock for riding safety. The direct reasons can be attributed to the lifecycle management negligence of the ropes that would have been replaced by the OEM or if there existed a comprehensive inspection agency required by law. While statutory laws and bylaws depend on regions and governments, the negligent bypassing of safety interlocks can be traced to a faulty maintenance system lacking checks and balances on regular planned preventive maintenance (PPM).

Bypassing Maintenance; Compromising Safety

There is a greater risk to elevator safety in the desire to economize maintenance costs. While appealing on a short-term basis, the long-term costs of substandard maintenance and associated risks are many. Maintenance is often interpreted as a breakdown rectification or a knee-jerk repair function in response to specific overt manifestations of a long-term hidden malaise.

There can be no substitute for well-planned and well-addressed PPM that periodically attends to all VT systems. OEMs are well organized in this with respect to their own equipment, but the degradation starts when the maintenance is sought and carried out by non-OEMs. The focus automatically shifts to trouble-free operation, rather than a planned inspection/verification and adjustment or replacement of components as dictated by the manufacturer.

Unregulated Maintenance

The unregulated maintenance of elevators done by non-OEMs, while appearing cost-effective, leads to additional costs, and risks life and limb in the long run. Non-OEM maintenance starts with a purely profit-oriented business model aimed at augmenting revenues and cash flow. There is a disconnect of ownership in this arrangement where the units would not be serviced as effectively as they would be by an OEM.

There have been many glaring examples of large-scale projects that have gone this route and ended with the creation of risky situations — some ending in avoidable accidents. Most of these get back to the OEMs and require wholescale replacements far costlier than the short-term savings.

End-User Awareness and Education

Many incidents are caused by the lack of awareness or as a result of a panic reaction by the public using the elevators. We all need to take a step back and see if at any point the manufacturers interact with the end users on a planned, regular basis. This needs to be done not as a simple “Dos and Don’ts” advisory, but in a more interactive and educative manner. This interaction program should be part of a customer-interaction program and not limited to any facility, but it can encompass a wide range of audiences and participants, from students in schools and colleges, to the general public and emergency-response services, such as the local police.

Specific incidents, facility-specific awareness, comprehensive user awareness, “Dos and Don’ts” and emergency responses should form part of the material that should be conveyed during these programs. These need to be consistently updated and refreshed in all areas for any manufacturer. This would raise awareness levels, prevent panic responses and elevate the safety levels of VT systems.

Conclusion

It is incumbent upon us, the manufacturers and all authorities concerned, to incorporate a self-regulative attitude that does not compromise on maintenance, tolerates zero bypass of interlocks and mandates the timely replacement of critical components, such as ropes, safety gears and

brake systems.

Summarizing our efforts at achieving 100%-accident-free elevators, we urge a comprehensive authority to investigate and analyze or collate details on every major elevator/escalator incident around the globe. This would facilitate a database references, which would form the basis for corrective/preventive actions by all concerned. We also request an introspection on the non-OEM-led business models that have limited revenue streams but result in more damage and loss of not only money, but also life and limb, in the long run. Should we, as professionals, concentrate on short-term revenue streams or long-term safety? Which checks and balances should the system have to provide effective maintenance solutions for the long term without compromising the safety of the users?

While we are all aware of the emergency procedures of how and what to do while traveling in an aircraft or a train, how many elevator users or passengers know what to do in an elevator emergency? Let us plan to create this awareness among one and all, for we all use elevators more often than we fly. It should be the right of the end user to be provided with this potentially lifesaving information.

Get more of Elevator World. Sign up for our free e-newsletter.