Making Dreams Come True

Jun 1, 2024

Company prides itself on a product for difficult designs.

Eng. Marco Santel (MS), owner and technical director, C.O.A.M., shares insights with your author (SSP) about the company’s entry into India with BESCO, market expectations and future plans.

SSP: How did your collaboration with Branded Elevator Solutions Company (BESCO) start off? Why did BESCO join hands with C.O.A.M.?

MS: The BESCO team had observed C.O.A.M. Italy and its products in the global market and were enthusiastic about it. So, they started off by buying one container of material and installing it. They were so happy there were no problems that they decided to formalize the relationship with C.O.A.M. That’s how we met BESCO Director Mr. Arun Narang and got to know about his company, as well.

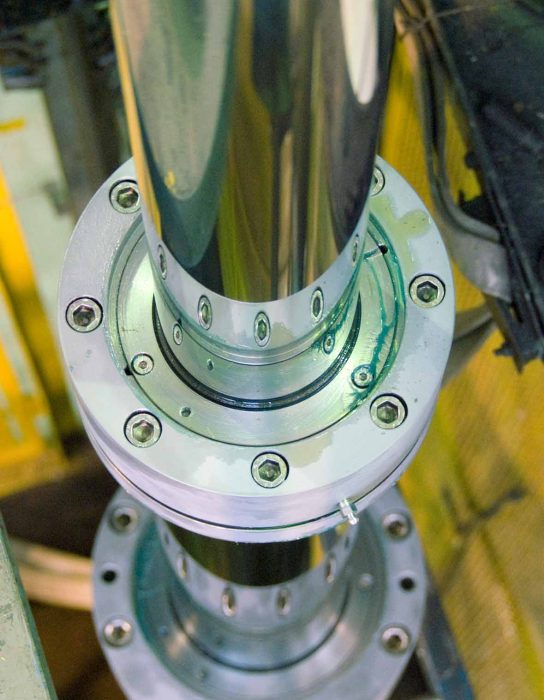

The reliability of the product is good everywhere, in any case. Once you put the hydraulic piston inside the shaft, you don’t want to take it out; it’s difficult. So, this is why Arun likes the product. He puts it in, and then he forgets it.

As a company, C.O.A.M. Italy has always been focused on quality. We also love to work on special projects, and the quality product we make is the right one to fit the needs of architects that design difficult structures or constructions. They need something that works and that is reliable, and that is where we find our place. The reliability of the product matters, so this is why Arun likes the C.O.A.M. brand and products.

SSP: What are your expectations from the collaboration?

MS: Arun is transforming the market to work in a certain way. He is training customers and teaching them the value of quality, the value of finding the right product and the good feedback that comes from installing good material. The cost you pay in the beginning will pay you back many times in the future, and this way of working is developing our market. I foresee a good response from customers.

I like to not just do only business; my mission is to provide opportunities for architects and customers to create something unique and creative. This is something we achieved with our German clients: They have been doing it for many years with very special elevators and good customers in Dubai and the Middle East with unique buildings. And I know that, in India, there are customers that are eager to build this kind of stuff, and I think it’s possible.

But, there is the need for architects who know it is possible to do strange things, beautiful things, without too much hanging on the walls, something slim. The architects need someone who backs them up because they can make drawings, but when there is nobody who can do the job, the drawing stays there. They want to make it real. And to make a dream come true, you need someone, some technician, some technology, some people who can do the job.

And what is not yet ready in India is the elevator technician, in my humble view. You have a lot of good people, intelligent people, but the hydraulic is not known enough. We are developing this knowledge.

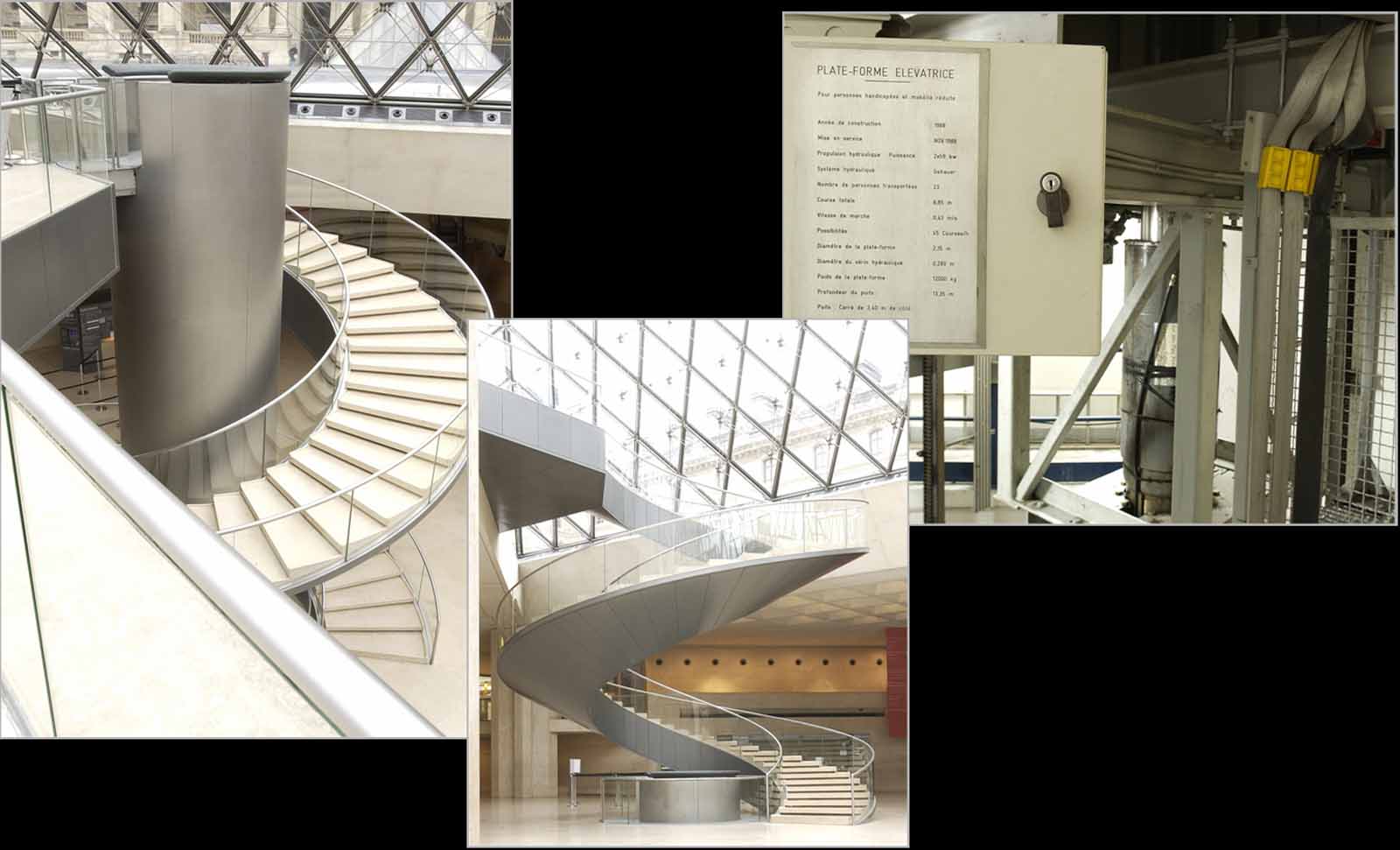

We have done many things of which we are proud, like the elevator in the Louvre Museum in Paris. We also helped the designer of the lift finalize the drawings. I provided the technology to do that. There are other, very nice lifts done with C.O.A.M.

In Spain, there is a lift with pistons that travels 37 m because there is no roof. There was no way to hang anything on the top, so the architect decided to make it with a central direct piston. We designed the piston from scratch for that. If an architect has something crazy in mind, they come to us. We cooperate with some specialized customers that are capable of doing such things, but it would be better to have companies directly in India to do the job.

SSP: How did you enter hydraulics, and what are the advantages?

MS: I have been working with C.O.A.M. since 1994 and was trained at Schindler. I, personally, have worked with some 30-t freight lifts at Paddington and the freight elevator of the British Museum, a five-story truck lift 25-mt long. It pops out of the ground at street level.

Hydraulics provide structural advantages, which make them good for architects — you don’t need to hang anything; everything is on the ground. It’s safe against earthquakes and easy to calculate, as all the weight is at the bottom of the shaft.

You can move the power wherever you like. There are lifts where the power units are 30 m away. It’s easy to put a cabinet beside the door and control the lift from there — small solution cabinet controllers with power unit included in the shaft and valve outside. That is for the power unit to separate from.

Hydraulic lifts are friendly in case of a power outage, so there is a red button on the power unit — if you turn it, the lift will come down. So, if you are aware of this, you enter the lift more easily. For geared or gearless machines, you need to call someone who operates the brakes and turns the lever to take you up and down; whereas in the case of hydraulics, it’s easy. Anyone can operate it. In case of failures, it’s easy to operate and is reliable.

Hydraulic lifts last for 30 years; here I am not talking about the controller that can be broken, but the power unit and piston are reliable. So, we have reliability, safety and structural solutions in the case of existing buildings. Here in India, it’s very easy to make a hydraulic lift with little headroom and pit, something good in case of existing buildings.

SSP: In which segments can hydraulics be implemented in India?

MS: Public structures, like train stations and airports, are a very important segment. These are usually taken by the multinationals, but they are not prepared to create unique things. They are not ready to do freight lifts or glass elevators. Independent companies can enter in those cases. There is a need for industrial warehouse production facilities to move loads up and down. I don’t see a problem of space here. There is a need for a solution for loading the trucks and moving loads up and down.

SSP: What kind of technology is required for making hydraulics sustainable for public transportation in India?

MS: I am a key supplier of Bucher Hydraulics; they have a wonderful product often used in subway train stations in England. The product moves the lift up and down using the inverter. When the lift comes down, the energy goes through the motor to the braking resistor or, in some cases, when it is allowed directly to the net, it has energy-saving solutions.

But in those cases, the architects know very well that the first thing to put in is an escalator. The escalator is the solution for moving a lot of people. The elevator is needed when you have a wheelchair, luggage and weights. There is always an elevator beside an escalator, and it can easily be a hydraulic solution.

SSP: Which are some of the unique creations you have observed made with your materials?

MS: I have seen lifts made with my material in the Armani store in Milan and the Lübeck museum in Lübeck, Germany. In some private houses in Switzerland, there are very beautiful elevators made without guides. Everything is brought up and down by the piston. There is only a tube of glass and a glass cabin. Everything is moved by something under the cabin, and there is a hole in the roof with glass. So, when the sun is out, the entire house is lit by the sunlight. It is a really beautiful project.

About C.O.A.M.

C.O.A.M. Italy, established in 1962, has cultivated extensive expertise in designing and manufacturing hydraulic components for lifts. C.O.A.M. is renowned for its “Smooth Ride” pistons and exclusively collaborates with industry leaders in the hydraulic elevator space.

In the realm of challenging projects, architects, designers and installation company managers of hydraulic lifts and elevators find invaluable support in the innovative prowess and seasoned experience of C.O.A.M.’s engineering division, led by Santel.

Originally focused on special and large systems, the company has expanded into a diverse array of products and solutions tailored to varied needs and applications. Its core competencies encompass not only design and manufacturing prowess but also timely delivery, adherence to quality standards certified by globally recognized organizations and adaptability to market dynamics and customer demands.

About BESCO

BESCO, short for Branded Elevator Solutions Company, is a premier provider of branded components and solutions to elevator companies throughout India. With a commitment to excellence and innovation, BESCO plays a pivotal role in the elevator industry by offering high-quality products and comprehensive solutions tailored to meet the evolving needs of its clients. The mission at BESCO is to empower elevator companies across India with top-notch branded components and solutions, enabling them to elevate their businesses and deliver exceptional experiences to their customers.

Get more of Elevator World. Sign up for our free e-newsletter.