Prestige, Made in France

Oct 1, 2020

by Kaija Wilkinson

photos © Nicolas Swickel

Otis has been involved with the vertical-transportation (VT) system at Stade Roland-Garros tennis complex in Paris for more than 40 years. A tennis fan, Otis New Equipment Director Léopold Bernard tells your author his favorite tennis player is Switzerland’s Roger Federer, who won the men’s singles title at the French Open (a tournament also known as Roland-Garros)[1] — hosted by Stade Roland-Garros — in 2009,[1] and holds records for both the most total weeks at No. 1 in the world (310) and most consecutive weeks at No. 1 (237).[2] Federer and the Otis-Stade Roland-Garros relationship were born around the same time (1981 and 1979, respectively). “I know saying Federer is your favorite player isn’t very original, but he’s incredible. He makes it look so easy,” Bernard says.

What hasn’t been easy is the ambitious transformation of Stade Roland-Garros that began in 2011, the 120th anniversary of the French Open. The project aims to respond to new expectations on the part of players, the public, partners and the media.” Those expectations entail higher, wider and less-crowded facilities served by a VT system incorporating high-tech features — digital media displays and touchless operation, for example — and striking design. Otis describes the stadium as one of its “prestige sites.”

Otis has performed technical VT studies on Stade Roland-Garros for operator the French Tennis Federation (FTF) since 2013, providing support for the prime contractor and site architects. In 2015, VINCI was selected as prime contractor. “Our teams worked tirelessly for an entire year to provide the best possible response to the tender call and to the regulatory constraints for an existing site that was open to the public,” Otis states.

In 2016, Otis was awarded its latest Stade Roland-Garros contract to provide 27 units over five years throughout the complex and courts, culminating in outfitting the events area with two panoramic elevators.

Upon full completion, Otis will have installed 64 units including:

- Four panoramic, 1000-kg duplex and three panoramic, 1000-kg simplex elevators in glass shafts

- Five 2000-kg freight elevators

- 26 1000-kg Gen2® Stream elevators

The Team

Otis France assembled a custom team to handle work at the “prestige” Roland-Garros site. They are:

- Director of Sales, France: Franck Milward

- Director of Clientele, Major Projects: Quentin Martinez

- Heads of construction: Emilie Brillault and Aurélie Leprand

- Project engineers: Marika Chikh, Jérôme Aubourg and Valentin Paugam

- Site engineer: Guy Sanches

- Site supervisor: Joaquim Pereira

- Equipment mounting technicians: Florian Doré (lead), Nourredine Nait Amer and Jonathan Gbadjamo

- 17 630-kg Gen2 Life elevators

- Three dumbwaiters by SKG Metallschneider GmbH of Salzkotten, Germany

- Five disability platform lifts

- One 1000-kg elevator with reduced shaft height by seca of Hamburg, Germany

Suppliers for the Stade Roland-Garros project were ones “with whom Otis has been working for a long time, because of their seriousness and demanding standards.” The primary supplier for Stade Roland-Garros’ VT equipment, however, was Otis’ manufacturing facility in Gien, France, approximately 153 km south of Paris, Bernard observes. “Providing local solutions means optimizing a project’s timeline and execution,” he says. “We’re proud to have delivered a project that’s almost 100% ‘Made in France.’” Other than the three dumbwaiters and the seca unit, all elevators and components were fabricated in Gien.

The most striking Otis units on the site are the panoramic lifts. As part of the most recent work thus far, the company has installed five of them: four on the main tennis court — Philippe Chartier — and one in the entrance lobby. Two more are coming in 2021 to a new public reception area that will feature animations of the stadium’s transformation.

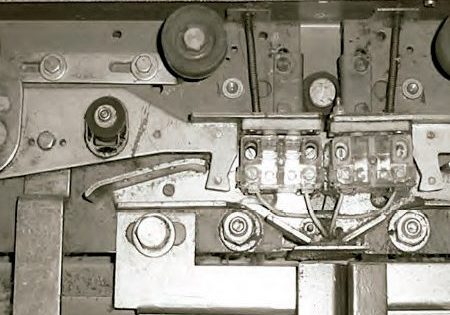

Most of the units installed over recent years are Gen2, which Otis describes as “an eco-designed and eco-efficient elevator and product line broad enough to meet all FTF requirements.” The units travel at 1 m/s between levels two and four in various structures on the site. Otis observes Gen2 optimizes dimensions and component weights and incorporates environmentally friendly materials such as lead-free paint and mercury- and cadmium-free circuit boards. They were key in Otis winning the work. Otis states:

“The technical components and the concern for environmental impact were among the strong points of Otis’ bids. The working methods and the expertise of our personnel also helped make the difference, since the project entails exceptional constraints (including its large scope and the need to deliver on each phase in order for the project to move forward).”

With a flat-belt system, gearless motor and compact machine, Gen2 incorporates reduced energy consumption, Otis states.

Gen2 Life, Stream and Stream High-Rise units — all of which serve Stade Roland-Garros — are classified “A” under the International Organization for Standardization Standard 25745. Otis observes:

“The strong point of our Gen2 units is ReGen drive technology. This system regenerates the energy produced by the elevator and returns it to the building’s electrical grid. It enables a reduction of up to 75% of the energy consumed by a standard hydraulic elevator. In this case, it enables compliance with BREEAM® certification, which is required by the FTF.”

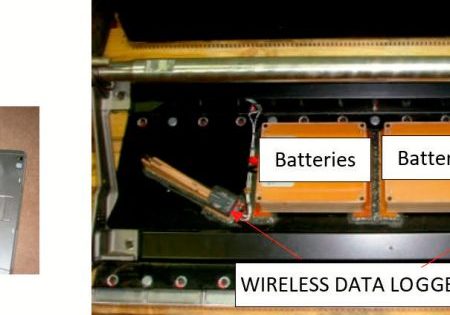

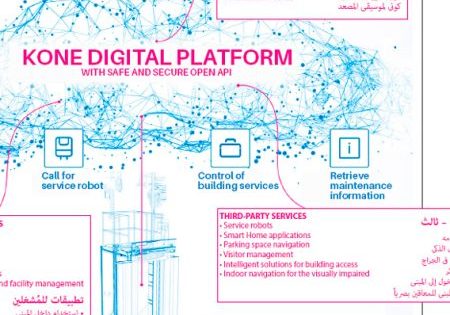

All Gen2 units at the stadium are outfitted with technologies including the Pulse automatic-surveillance system, REM remote surveillance and Elite remote-diagnostic system. Fifty percent of the units are outfitted with eViewTM screens, which provide “customized information to passengers, enriching their trip by sending information in real time.” eView also allows direct video communication with Otis technicians. All units can be connected to Otis ONE, an IoT solution that enables predictive maintenance.

Open, Airy and Green

Ahead of the 2019 tournament, at which Spain’s Rafael Nadal emerged victorious,[3] 80% of the main (Philippe Chartier) court was demolished and replaced with a more expansive, open structure, Otis observes. Now with a retractable steel and canvas roof, the court area was heightened from 18 to 26 m and widened from 85 to 105 m. Bleachers were widened from 8 to 10 m, but capacity— 15,000 — remains the same. This is a welcome change, especially in light of the COVID-19 pandemic.

More breathable space fits into the FTF’s overarching pursuit of “revegetating” the complex, part of its corporate social responsibility effort that boosts both oxygen levels and aesthetics. “The 2019 edition of the emblematic Parisian tournament promoted how important it is to cherish nature and biodiversity inside the stadium grounds,” the FTF observes, “because going to Roland-Garros is a bit like going for a stroll in the country.”[4]

Landscape architect Michel Corajoud drew inspiration from the nearby Bois de Boulogne public park for a plan that includes a “central walkway transformed into a contemporary green belt” and the new semi-sunken Simonne-Mathieu Court cradled within four greenhouses housing plants from five continents. The new court comfortably seats 5,000 spectators and is intended to illustrate FTF’s goal of the alliance of sports and nature.[4]

Working During the Pandemic

VT work continued at Stade Roland-Garros throughout the pandemic. “This site is one of the rare ones where security measures were adopted and put in place from the start of confinement in order to continue work with a reduced workforce,” Otis states. Starting in March, only 10 VT professionals, four of whom were Otis technicians, were permitted onsite. Six subcontractors performed associated tasks such as metalwork, masonry and cleaning, while the Otis technicians assembled, adjusted and conducted test runs on the units.

It took the team only four months to install 27 units, which meant a heavy workload that included nights and weekends. “We needed to adapt in order to deliver high-quality work in a very short time and within a gigantic overall project,” Otis states, continuing:

“Roland-Garros is a very big project and a very important showcase for Otis. The site is being managed with an extreme high demand for quality. It’s a huge source of pride for our teams to be a part of it. It’s a benchmark site that we want to hold onto by continuing to supply and maintain units to a very high standard.”

At press time, the FTF planned to host the 2020 French Open on September 27-October 11, with pandemic-related adjustments in place.

About Stade Roland-Garros

Named for a famous French aviator, Stade Roland-Garros was built in Paris in 1928 and today is considered a premier worldwide sporting venue that hosts the French Open, one of the four tennis tournaments that make up the Grand Slam. Before it was built, early tennis championships were held at the Racing Club de France, then the Stade Francais. Known for its red-clay courts, Stade Roland-Garros originally covered 4.25 ha (8 acres) and had five courts. In 1968, the Internationaux de France became the first “open” tournament of the Grand Slam.

The first extensions date back to the 1980s. Since then, the stadium has undergone several major transformations, giving it a total area of 8.5 ha (21 acres) with 20 courts, including the two central ones, Philippe Chatrier and Suzanne Lenglen. Reported by Otis France with information from the French Tennis Federation

References

[1] wikipedia.org/wiki/Stade_Roland_Garros

[2] wikipedia.org/wiki/List_of_ATP_number_1_ranked_singles_

tennis_players

[3]wikipedia.org/wiki/2019_French_Open_%E2%80%93_

Men%27s_Singles

[4]rolandgarros.com/en-us/article/roland-garros-2019-goes-

green

Get more of Elevator World. Sign up for our free e-newsletter.