Warrenville, Illinois-based company details advantages of a tougher material in this Product Spotlight.

submitted by Plymouth Engineered Shapes

When an elevator is out of service, the minimum cost to replace a sill or repair the doors from a damaged sill will include the sill replacement cost; service cost of the local elevator service provider; and, most importantly, the ultimate cost for customers who no longer have the elevator available to them while it is being repaired. Additionally, how often does one have to replace a worn sill or work on the doors? Money can be saved on the installation by putting in a less-expensive sill, but is it worth it in the long run?

The solution is to install stainless-steel sills during initial construction or modernization and have the peace of mind that comes with them. Stainless-steel sills provide structural strength capable of withstanding heavy traffic and harsh/corrosive environments. Plymouth Engineered Shapes’ stainless-steel sills are used in high-wear and corrosive areas, including high-end properties, waterfront properties, municipality mass-transit lines, hospitals, airports and numerous other locations where quality and durability are a must. They are also being used because of the appealing look they offer, which can be improved with polishing. A building owner can have a sill that will match or complement its stainless-steel entrance and interior.

Some of their benefits include:

- The surface of stainless-steel extrusions minimizes or eliminates finishing. Standard mill finish is offered, but many choose to have their sills polished for a more refined look.

- High structural strength can withstand heavy traffic and harsh/corrosive environments.

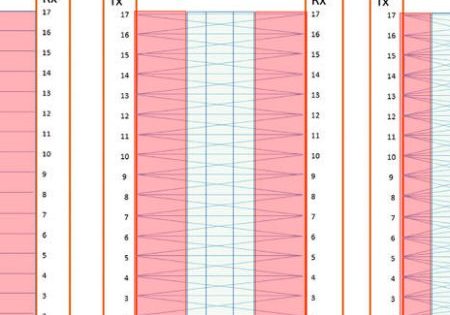

- Custom designs and shapes, as well as single- or double-speed options, are available, in both cab and hoistway configurations.

- Extruded stainless-steel elevator sills, sill extensions and thresholds can lower processing costs and reduce material waste.

- The maximum cross-section is 5-1/2 in. wide.

Plymouth Engineered Shapes, A member of Plymouth Tube Co., manufactures extruded stainless-steel sills, sill extensions, handrails, handrail hangers and other architectural components for the elevator industry. Plymouth prides itself in providing customized extrusions specific designs or offering standard sill profiles. While it manufactures sills with 304 and 316 stainless steel, it also offers 1018 carbon steel sills to replace cast iron ones.

www.plymouth.com/engineered-shapes-2

Get more of Elevator World. Sign up for our free e-newsletter.