The goal of great companies is to build industrywide platforms to bring together a broad ecosystem of partners.

by Onur Artıkoğlu

This article was first presented at the 2019 International Elevator & Escalator Symposium in Las Vegas. For more information on December 6-7, 2021’s event in Amsterdam and to participate, visit www.elevatorsymposium.org.

Can “technology” and “sustainability” even be used in the same sentence? In other words, shall today’s companies provide sustainable technological solutions for their customers?

In today’s changing world, “technology” companies have taken the lead from the legacy industry leaders. These companies were established as startups, but they easily penetrated to end users’ minds via their user-friendly products or connected services or internet platforms that make people’s lives easier or more fun. Then, the question, “Are the solutions they provide ‘sustainable’?” arose. If the strategy is adhered to strongly enough, and if you build trust with more freedom, the answer is clearly “yes.” The promise of internet platforms is to harness the information of millions of individuals without relying so much on corporations, which can take advantage of their positions to serve their own interests. With digital platforms tapping into the wisdom of crowds, we can have the best of both worlds: a system based on individuals and voluntary choices that also harnesses more information than has been historically available to any individual or company.

Great companies don’t just try to build great products or services, especially in technology-driven markets. Their goal is usually to build industrywide platforms to bring together a broad ecosystem of partners engaged in complementary product and service innovation, as well as in related marketing, sales, service and distribution. First, they build trust; then, with the support of collaboration, they transform this to efficiency with their specialized products. So, apart from the “startups,” giants like Intel, Apple and Microsoft did it well and managed their transformation properly to provide sustainability. I call it “continuous change management.”

The vertical-transportation (VT) industry is one of the most interesting, with a unique impact to its final consumers. With its history, and in terms of product/service/technology perspectives, technology progress seems quite slow when compared to that of other industries. Lately, the trend is moving in the opposite direction. Industry leaders competing with their Internet of Things (IoT)/artificial-intelligence/connectivity solutions started to satisfy their final customers. The main change here is not the unstoppable developments in the technology; it is to hear what the customer needs. Steve Jobs, founder of Apple, had a famous saying regarding this: “It’s really hard to design products by focus groups. A lot of times, people don’t know what they want until you show it to them.” Jobs always targeted the “non-existing need.” He wanted to be the one who created “the need.” But, Apple never underestimated the feedback from the customer. With these two factors combined, Apple transformed into a sustainable technology-driven company.

When Otis started the “urbanization era” with the help of safe elevators’ innovation, the company also pioneered predictive-maintenance efforts years ago, before we ever heard of IoT. Back in the 1980s, Otis created the Remote Elevator Monitoring (REM) initiative, collecting data, like fault codes and the number of times a door opens, from more than 300,000 of its elevators. Otis collected that data once a day from those remote sites at baud-modem speeds. Now, the company can use those 40 years’ worth of REM data and insights as part of its predictive analytics program.

Why do companies collect data? Especially for an industry like VT, what would be the triggering point for Otis to have started to collect data almost 40 years back? Is the collected data even usable? It certainly must be convertible and usable in its final phase. Within a connected digital ecosystem, information is gathered directly from the elevators and escalators via smart-sensor technology, sent wirelessly to the cloud, analyzed and optimized through the connected platforms and delivered to the dedicated service team. Finally, it is delivered to the final consumer as a “sustainable product.”

This intelligent connectivity not only ensures the systems are up and running more often, delivering a better experience for riders, but also delivers faster service and greater cost savings to the business (industry). In short, whereas REM was for that day, IoT is for life. When the industry leaders with their strong strategists invest in the technology to start “the new era” for sustainable urbanization, it will create more and more happy end-users to shorten the return-on-investment period more than ever.

Today, Otis works to predict problems on the more than 2 million elevators it manages before those problems happen. This is the first part of the company’s digital transformation. In essence, Otis can proactively repair many elevators before they go out of service. This move decreases the carbon-emission values with fewer call-backs to Otis technicians, increasing efficiency in all areas.

For instance, Otis technicians now have a new app on their company iPhones, Tune, which predicts maintenance needs based on the sounds an elevator is making as it travels from the bottom to the top of its route. That’s something longtime maintenance professionals could detect with their experienced ears. In creating Tune, Otis relied on machine learning, using audio data to train the algorithm, while not underestimating the true impact of pure experience. It was a way to level up via the latest tools without leaving the core human experience. Remote monitoring can listen for the sounds that, when taken to the next step, can predict a future problem and dispatch a field technician with the right tools and parts to fix it before a service interruption occurs.

Elevators today are equipped with several sensors that can detect everything from noise, to vibration, to weight thresholds, to atmospheric pressure. That data is then sent via gateways enabled by WiFi or mobile data back to the cloud. All these efforts are to create a target: what the final consumer will need. Once this is identified, it is created. This can have three outcomes: a transparent, predictive and/or proactive approach to products and services.

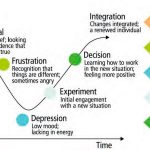

To create value and provide sustainability, as repeatedly executed by companies like Apple or Microsoft, there should be a very strong “change management” plan in place. Adopting all digital tools to daily operations is not easy and will go through stages (Figure 1).

Although most companies and executives know how crucial it is to evolve with technology and create digital processes and solutions, putting this into action is a different story. Many companies have endeavored to undertake digital transformations, only to hit roadblocks. Understanding what went wrong with some companies can provide guidelines of things to avoid and point future digital transformations in the right direction.

Lessons learned:

- Focus on quality, not quantity: General Electric Co. tried to do too much without a real strategic focus in any area. The company was simply too large to transform all at once, especially without a true vision of what it was trying to achieve. Digital transformations are often done best with a handful of passionate people leading the charge, instead of thousands of employees.

- Integrate digital transformation efforts with the rest of the company: In this case, digital transformation is less of an actual transformation and more of a pivot into a new business area. To be successful, digital transformation needs to be integrated into the levels of the company. Efficient and trust-making internal communication is the key to achieve this.

- Look at the competition: The return on investment for a widespread and expensive digital transformation was small, especially with signs of an economy on the brink, for Procter & Gamble Co. The company likely could have seen more success if it had focused on smaller digital efforts more targeted to its existing products and processes. It failed to look at what was going on in the industry to see it was already ahead of competitors and what was going on with the economy. A digital transformation for transformation’s sake won’t be effective. It must consider all outside factors and be tightly tied to strategy.

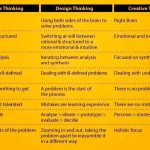

- Design-thinking mindset: In the VT industry, due to its historical characteristics, companies are led by more business-thinking mindsets. Completely opposite ones, like technology-based startups, were led by more and more creative-thinking mindsets. To be able to provide more and more sustainable services to final consumers, elevator companies need to combine the two and must lead by a design-thinking mindset (Figure 2).

A digital transformation is a complicated and risky endeavor. When done correctly, it can lead to amazing, futureproof results and start “new eras” with 100%-satisfied end-users. Otis, with its forward-thinking plan, in execution since the 1980s, now starts “the new technological era” in the industry, after starting the urbanization one in 1852. This is what the industry needs — moreover, what the customer will need — that increases satisfaction, availability and continuous performance improvement.

- Figure 2

- Figure 2

Get more of Elevator World. Sign up for our free e-newsletter.